E6581697

F-51

6

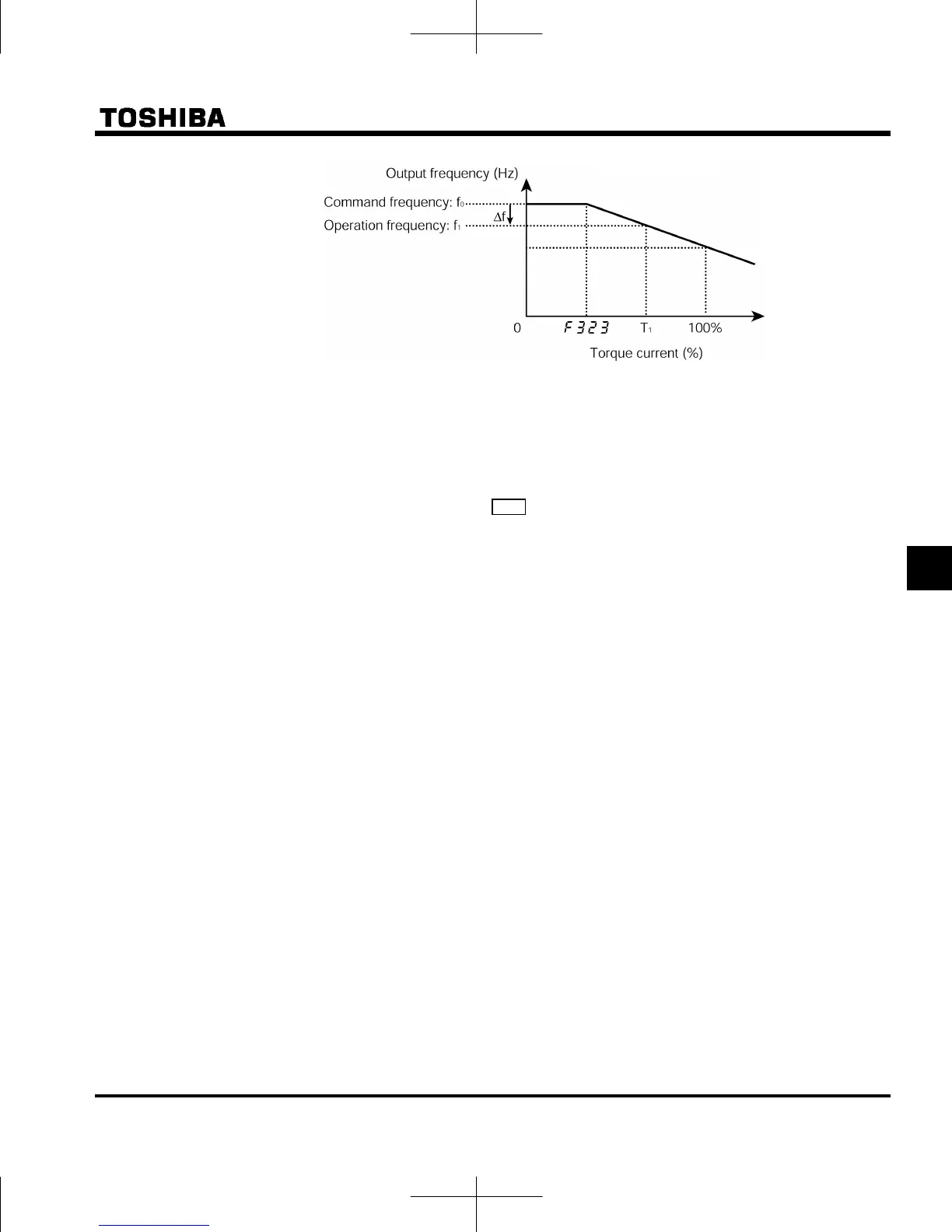

, The droop control function refers to the function of operating the power-running motor at operating

frequency f

1

(Hz) that is lower than command frequency f

0

(Hz) by droop frequency Δf (Hz) when the

torque current is T

1

(%). (See the above figure.)

The droop frequency Δf can be calculated, using the following expression.

Droop frequency Δf (Hz)=base frequency

vl × f320× (Torque current T

1

- f323)

When the torque current is above the specified droop insensitive torque band (f323), the frequency is

reduced during power running or increased during regenerative braking. The above figure shows an

example of the operating frequency during power running. During regenerative braking, control is

performed in such a way as to increase the frequency.

The droop function is activated above the torque current set with f323.

The amount of droop frequency Δf varies depending on the amount of torque current T

1

.

Note: If the base frequency

vl exceeds 100Hz, count it as 100Hz.

Control is exercised between the starting frequency (

f240) and the maximum frequency (fh).

[An example of calculation]

Parameter setting: Base frequency

vl=60 (Hz), droop gain f320=10 (%)

Droop insensitive torque band

f323=30 (%)

Droop frequency Δf (Hz) and operating frequency f

1

when command frequency f

0

is 50 (Hz) and torque

current T

1

is 100 (%) are as follows.

Droop frequency Δf (Hz)=

vl × f320 × (T

1

- f323)

=60 (Hz) × 10 (%) × (100 (%) - 30 (%))

=4.2 (Hz)

Operation frequency f

1

(Hz) = f

0

- Δf = 50 (Hz) - 4.2 (Hz)=45.8 (Hz)

Power running

Loading...

Loading...