23/68

7. OPERATION

7.1. Safety instructions for operating the product

• A damaged or malfunctioning machine must never be used. If damage or

malfunctions are discovered during pre-operation inspection or function tests,

themachine must be tagged and removed from service.

• The operator should wear safety glasses, hearing protection, safety shoes and

safety gloves when using or maintaining the solid tyre press.

• To prevent burns, fire and explosion, regularly check all pipes, hoses and

tubes. Never bend or crush the pipes! Have damaged pipes or hoses repaired

immediately.

• Prevent an unexpected and/or incorrect start-up of the solid tyre press at all times.

• Never use the solid tyre press when the workplace is damp or wet.

• Never use the solid tyre press in the rain.

• Prevent oil leakage or spillage at all times to avoid the risk of slipping.

• Do not wear loose clothing so that the clothing cannot get caught in the solid tyre

press.

• Only people who work with the solid tyre press may be in the vicinity of the device.

Other people must keep a minimum distance of 3metres.

• Provide additional lighting if visibility is restricted in the work area.

• Pneumatic tyres cannot be fitted using the solid tyre press.

• Tyres and tools weighing more than 25kg must be lifted by two persons.

• Make sure you have a full view of the work area.

• Never allow the oil pressure to exceed 230bar.

7.2. Operating instructions

Please see chapter8 for the daily maintenance schedule.

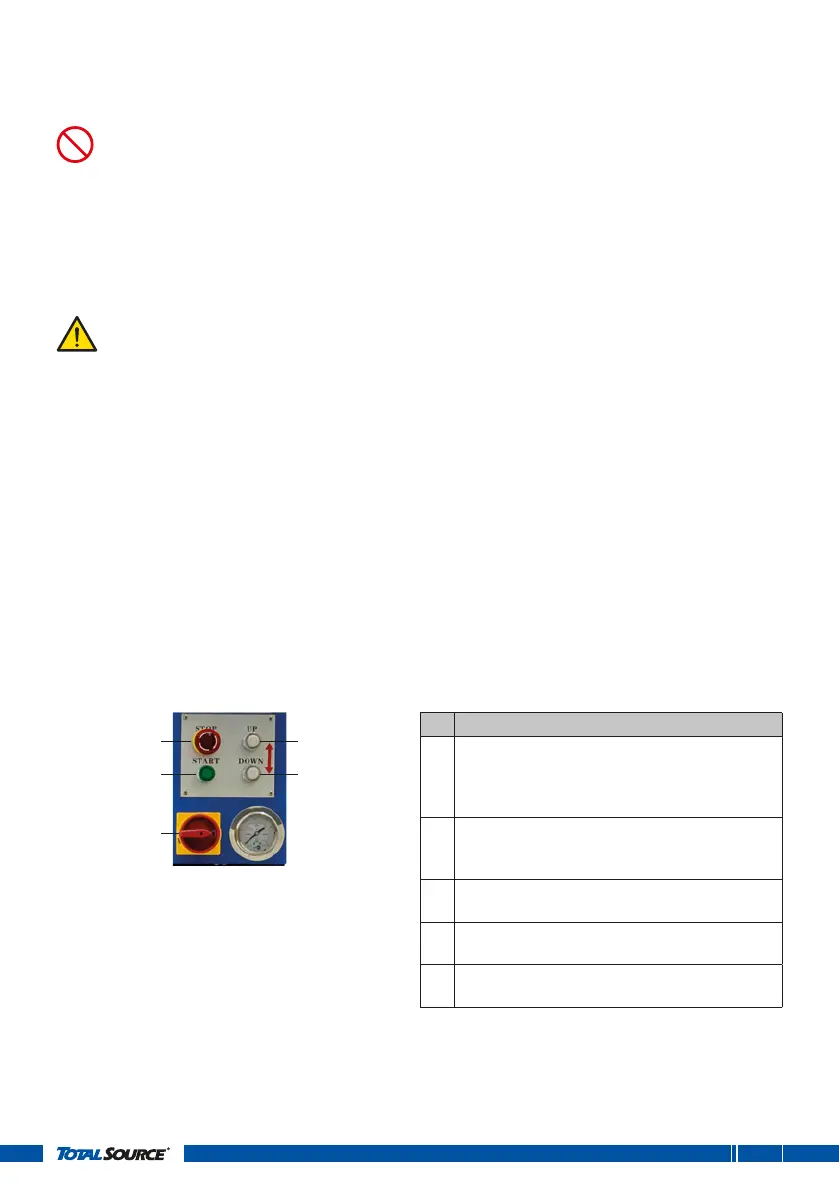

1. Controls

N° Explanation

1 EMERGENCY STOP SWITCH + STOP button:

1. Turn this knob a quarter turn to switch

the unit off completely in an emergency

2. Press to stop the tyre press

2 START button: Press and hold this button

until the green light comes on to start the

motor

3 UP button: Press and hold the button to raise

the piston

4 DOWN button: Press and hold the button to

lower the piston

5 MAIN SWITCH: Turn the knob a quarter turn

to start the device

Loading...

Loading...