5-1

f:tec\manuals\Service\SERVICEv5.indd - V6-0615

Valve Removal

Close all manual wheel end valves to prevent loss of tire pressure during rebuild and drain wet tank.

Label each Y-fi lter as to position on valve box.

Disconnect coupler between Y-fi lter and 90

o

pipe fi tting on right side of box.

CAUTION - Air line will be pressurized. Bleed line slowly until pressure is depleted.

Remove 90

o

pipe fi tting from box assembly (see page 5-4)

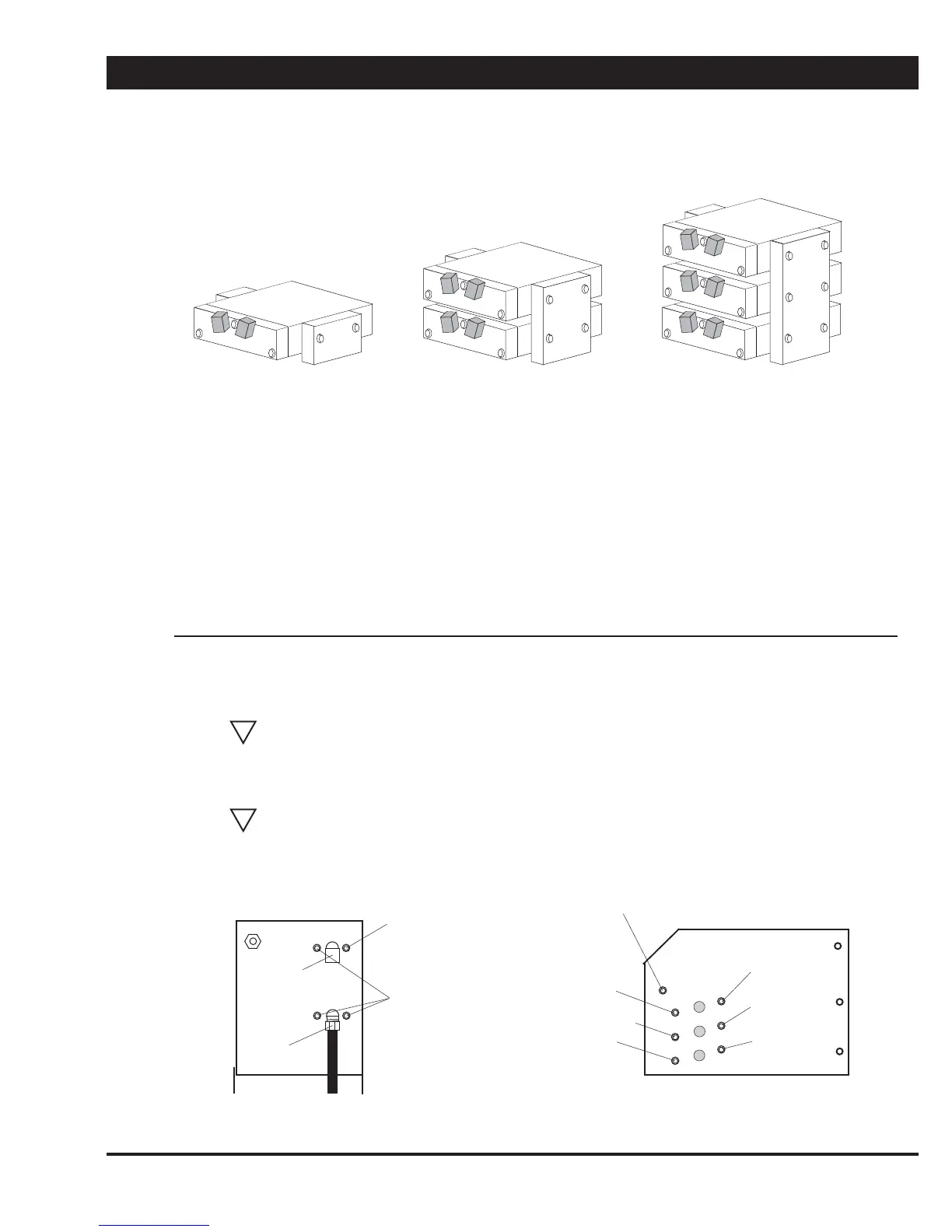

On bottom of box, remove 1/4” bolt to right of exhaust outlet and remove exhaust outlet. (See diagram

below). Then disconnect 5/8” air supply line and remove 90

o

fi tting.

NOTE - It is recommended to turn a bushing into exhaust fi tting to avoid crushing

during removal

Remove remaining 1/4” bolts as shown

Remove

Remove

(if equipped)

Remove

(if equipped)

Remove

Remove

(if equipped)

Remove

(if equipped)

EXHAUST

OUTLET

AIR

SUPPLY

This bolt will have to

be removed prior to

removing Exhaust

Outlet

Remove after remov-

ing Exhaust Outlet and

Air Supply fi ttings

BOTTOM OF BOX RIGHT SIDE OF BOX

TIREBOSS

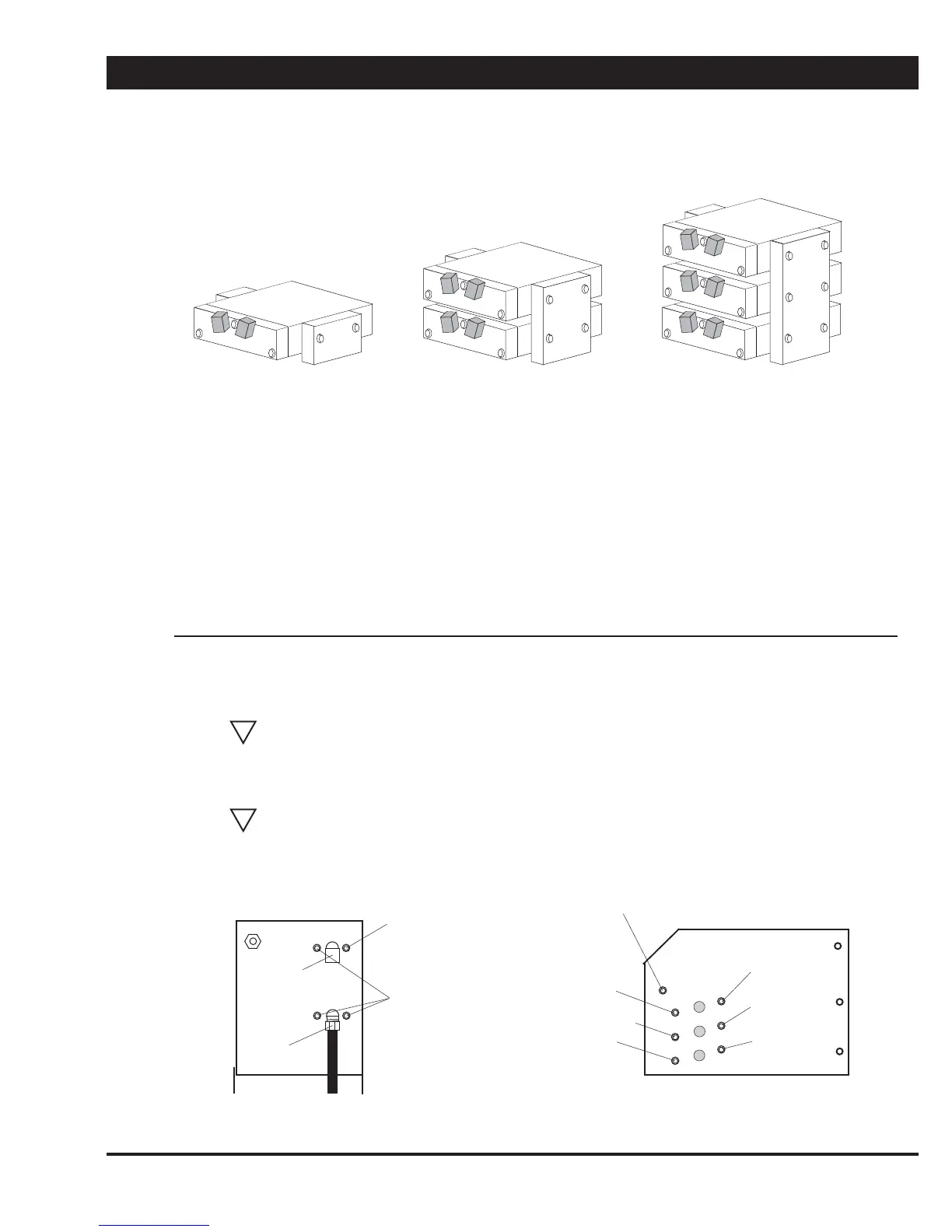

TM

Tire Pressure Control

ONE ZONE SYSTEM

(Eg. drive tire

control only)

TWO ZONE SYSTEM

(Eg. drive and steer or drive

and trailer tire control)

THREE ZONE SYSTEM

(Eg. drive, steer and

trailer tire control)

TIREBOSS

TM

Tire Pressure Control systems have either 1, 2 or 3 valve bodies depend-

ing upon the application. The following pages are the rebuild procedures for a single valve

body. Repeat the process for each valve body if required. When working with more than one

valve body ensure all cable harness’s and air lines are returned to the original position when

reassembling the valve bodies. NOTE - One VALVE PACK MAINTENANCE KIT is required

for each valve in the TIREBOSS

TM

system.

Note.. On three zone systems only, the two front

bolts and lock nuts supporting the Valve Control Module

Bracket will have to be removed in order to tilt bracket to

allow room for valve assembly removal.

VALVE REBUILD PROCEDURE

!

!

Loading...

Loading...