5-2

f:tec\manuals\Service\SERVICEv5.indd - V6-0615

Valve Disassembly

CAUTION - Systems with valve heaters only- Do not damage valve heater and foil on bottom

of valve. Do not submerse in cleaning fl uid as this will damage heater.

Remove solenoids from valve and discard O-rings.

See parts BREAKDOWN DRAWING #1.

Remove 3 - 1/4” bolts to disassemble face plate from valve body and discard rubber o-rings

Pull valve cartridges from valve body, using needle nose vice grips on centre allen screw, and put aside for

cleaning at a later stage

Remove 1/4” manifold bolts on side of valve body and discard o-rings

Remove inlet check valve and 1/4” air line fi tting using a 6 point socket only.

CAUTION - Use caution when removing these fi ttings. Do not damage push-to-lock.

Remove paper gaskets from valve body

Clean valve body and manifolds. Blow air through all passages. Ensure all passages are free of debris and

completely free of any cleaning materials before reassembly begins.

Valve Cartridges

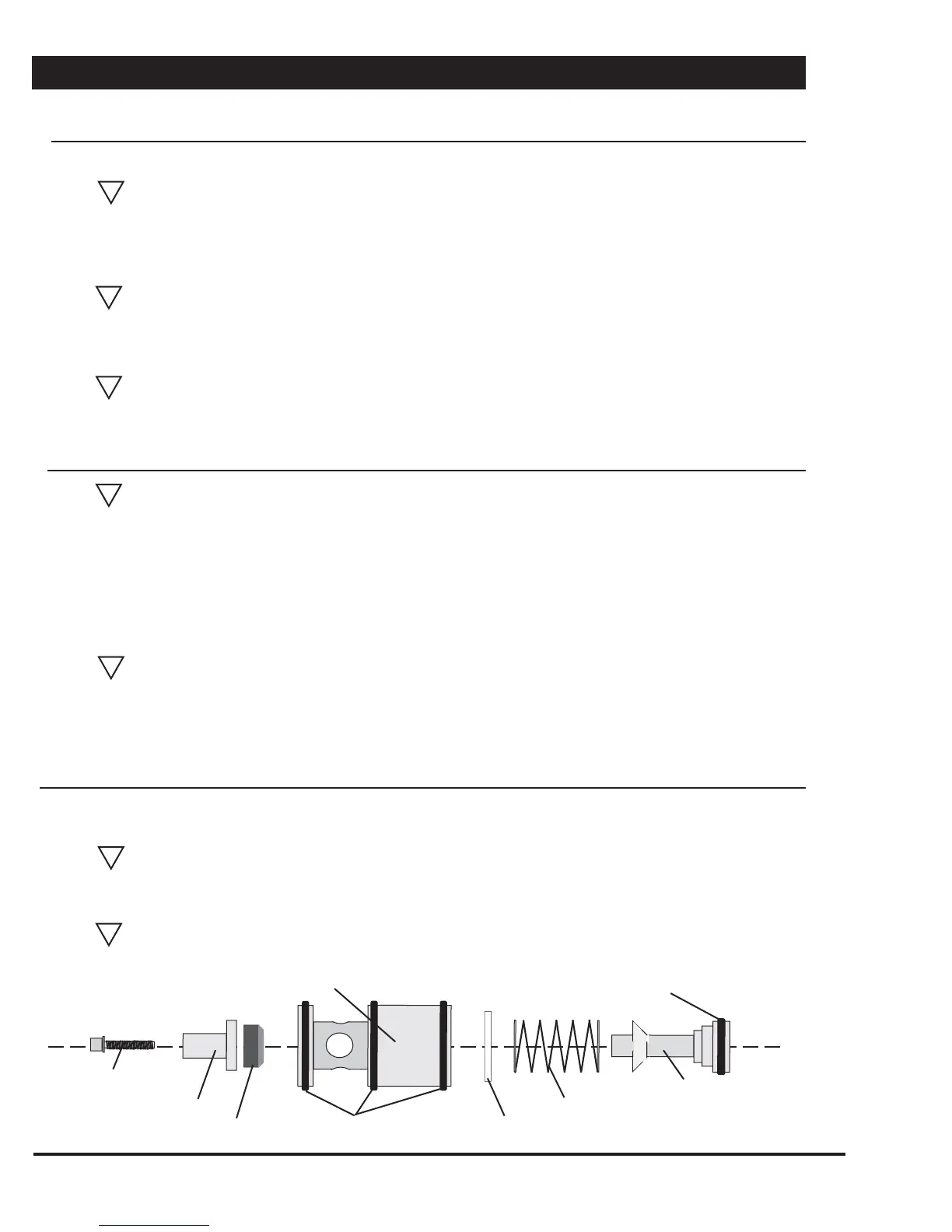

Using two allen wrenches (for old style) or allen wrench and two 1/4”bolts (for new style), disassemble

valve cartridges. Clean all parts. See parts BREAKDOWN DRAWING #3.

NOTE - Do not soak rubber components in varsol or strong cleaners. Rubber will swell and

deteriorate

Assemble valve cartridge with new O-rings (four in total) replacing valve seat poppet. If valve seat or

body is damaged, replace the entire valve cartridge (part #16750).

CAUTION -Take care not to over tighten allen head screw as damage to valve piston

shaft may occur.

VALVE REBUILD PROCEDURE con’t

Disconnection inside box

Remove 1/4” plastic airline from valve

NOTE - It may be necessary to remove line from static tank fi rst to allow enough movement

to disconnect from valve

-Systems with valve heaters only- Cut tie strap from wire bundle and un-plug heater harness

Turn valve body sideways in box to allow access to solenoids. Mark solenoid cables and harness posi-

tions to ensure they are reinstalled in original position during re-assembly.

NOTE - (Red/Green lead on left side and Black/white lead on right side)

Remove solenoid harness’s by removing mount screws.

-Systems with valve heaters only- Remove Robertson #2 screw on thermistor to detach from valve body

Remove valve assembly from box.

NOTE -On three zone systems only, the two front bolts and lock nuts on the Valve Control

Module Bracket will have to be removed in order to allow room to remove valve assembly.

(see page 1)

Replace O-rings

Valve Piston Shaft

Spring

Allen Screw

Brass End Cap

Valve Seat Poppet

Cartridge Body

Spring Washer

Replace O-ring

!

!

!

!

!

!

!

Loading...

Loading...