Installation

WSHP-SVX01L-EN 59

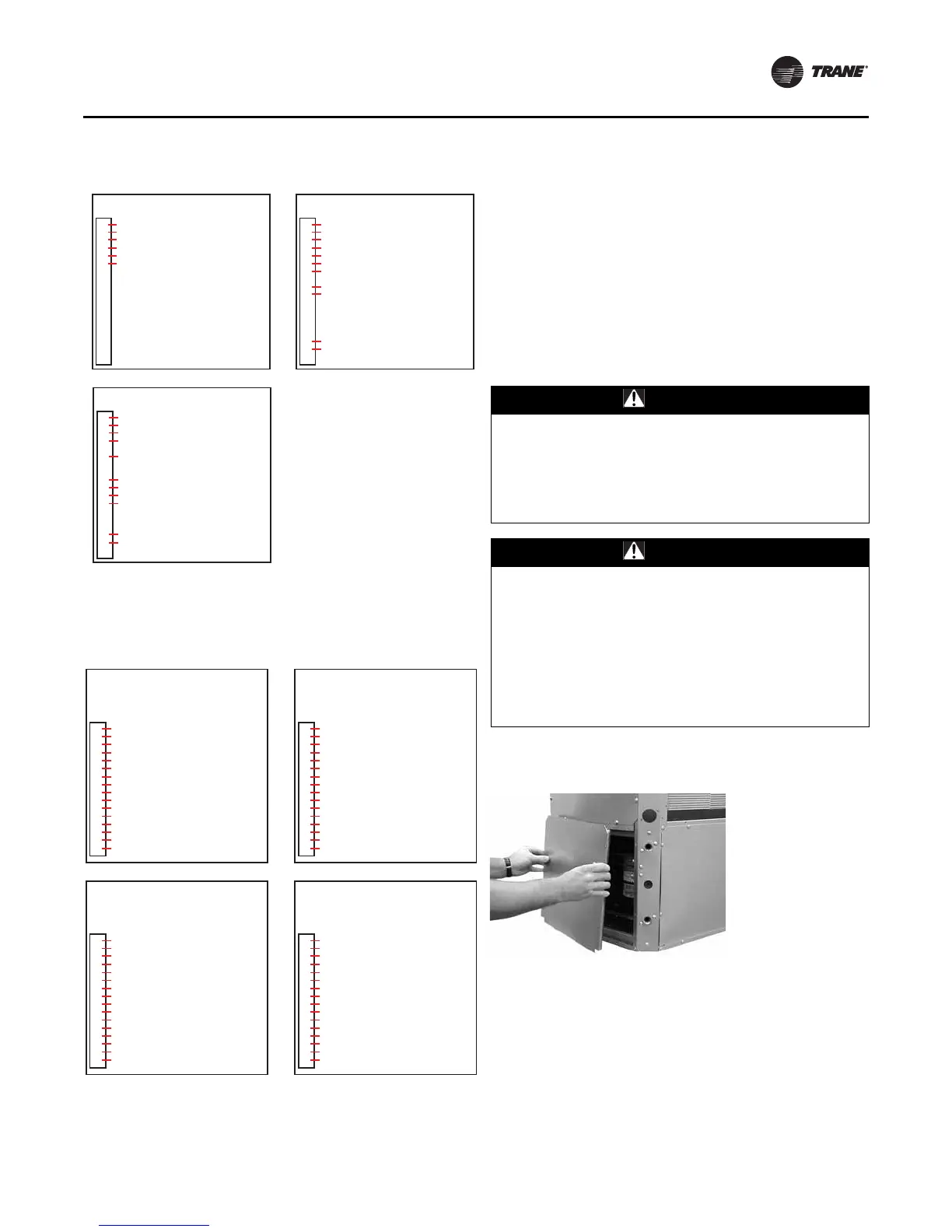

Low-voltage connection diagrams for basic and deluxe 24

V control packages mounted on ½-5 ton equipment sizes

are shown in Figure 58, p. 59.

Low-voltage connection diagrams for deluxe 24V control

packages for these thermostats mounted on 6-25 ton

equipment sizes are shown in Figure 59, p. 59.

For controls using DC analog input/outputs, see

appropriate installation, operation and diagnostic

manuals for connection. WSHP-IOP-2 (ZN510) and WSHP-

PRB002-EN (ZN524).

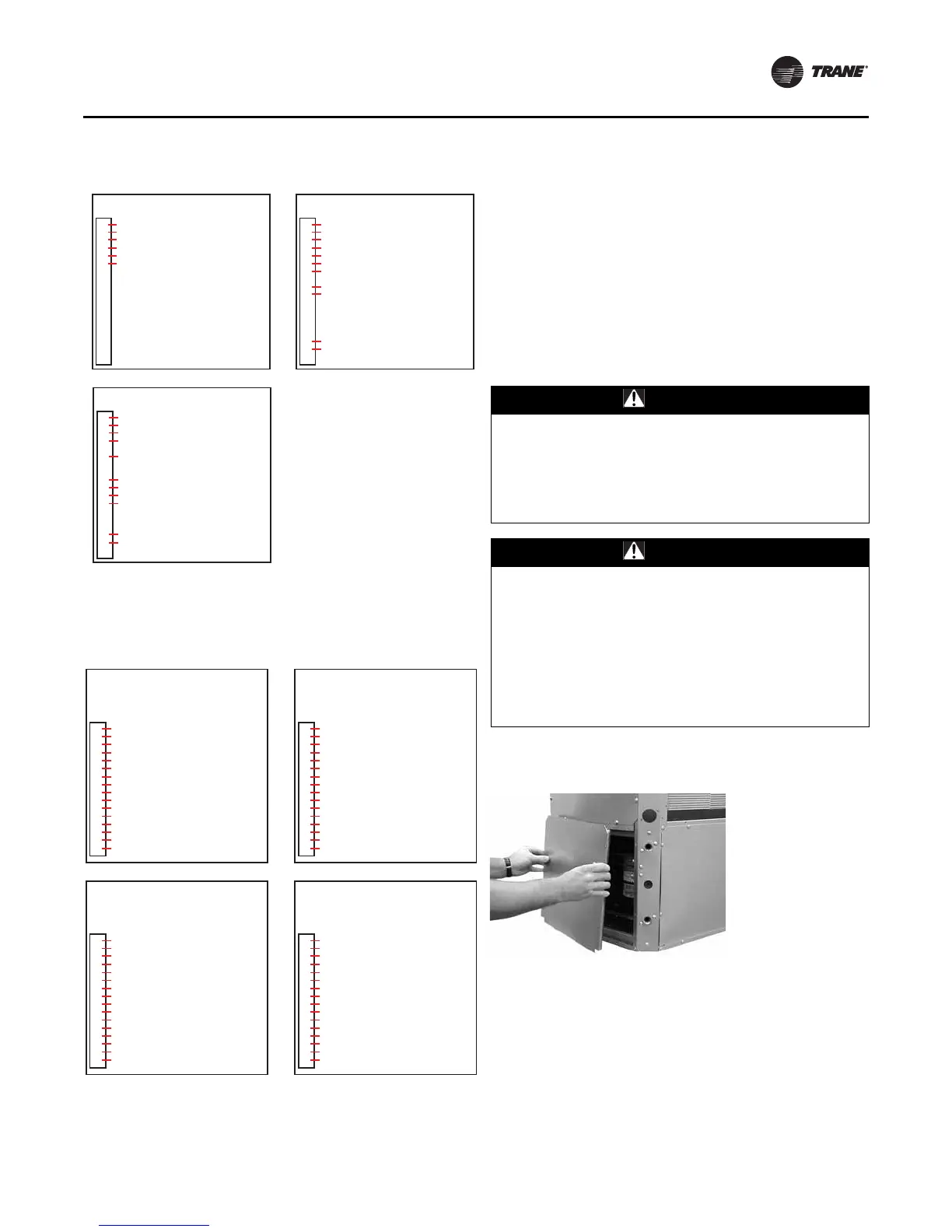

Blower Motor Speed-Tap Retrofit

Note: For GEH/V ½-5 ton units only.

Motors installed in the unit include 4-speed and 3-speed

configurations. All voltages include a 4-speed

configuration, with the exception of 380V, 415V, 460V

which contain a 3-speed arrangement and 575V which

contains a 2-speed arrangement. To modify the rpm of the

motor, the following steps must be followed.

1. Remove service access panel at the unit front.

Figure 58. Low-voltage connection (GEH/V ½-5 ton and

EXH/V 1½-6 ton equipment)

Figure 59. Low-voltage connection (GEH/V 6-25 ton)

Basic Controls Wall Mounted Thermostat

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1TB1

24 VAC

FAN

REVERSING VALVE (COOL)

COMPRESSOR & VAR SPD PUMP SOLENOID

24 VAC GENERAL ALARM OUTPUT

24 VAC COMMON & VAR SPD PUMP SOLENOID

Deluxe Controls Wall Mounted Thermostat

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1TB1

24 VAC

FAN

REVERSING VALVE (COOL)

COMPRESSOR & VAR SPD PUMP SOLENOID

24 VAC COMMON & VAR SPD PUMP SOLENOID

ELECTRIC HEAT (COOL ONLY W/ ELEC HT UNIT)

24 VAC COMPRESSOR DISABLE INPUT

24 VAC COMPRESSOR DISABLE INPUT

ALARM CONTACT OUTPUT

ALARM CONTACT OUTPUT

Deluxe Controls With Reheat

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1TB1

24 VAC

FAN

REVERSING VALVE (COOL)

COMPRESSOR

24 VAC COMMON & VAR SPD PUMP SOLENOID

24 VAC COMPRESSOR DISABLE INPUT

24 VAC COMPRESSOR DISABLE INPUT

HUMIDISTAT

VAR SPD PUMP SOLENOID

ALARM CONTACT OUTPUT

ALARM CONTACT OUTPUT

Deluxe Controls with

-all Heat Pump Units w/ Reheat

using X13511090010 (T8511)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1TB2

24 VAC (R)

FAN (G)

COMPRESSOR 1 (Y1)

COMPRESSOR 2 (Y2)

REVERSING VALVE (0) & HUMIDISTAT

24 VAC COMMON (C) & WATER ISOLATION VA

COMPRESSOR DISABLE

COMPRESSOR DISABLE

ALARM

ALARM

ELECTRIC HEAT

ELECTRIC HEAT

HUMIDISTAT

WATER ISOLATION VALVE

3RD STAGE HEAT (W3)

NOT USED

Deluxe Controls with

-all Heat Pump Units w/ Reheat

using X13511091010/X13511092010 (T7300)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1TB2

24 VAC (R)

FAN (G)

COMPRESSOR 1 (Y1)

COMPRESSOR 2 (Y2)

REVERSING VALVE (0) & HUMIDISTAT

24 VAC COMMON (X) & WATER ISOLATION VA

COMPRESSOR DISABLE

COMPRESSOR DISABLE

ALARM

ALARM

ELECTRIC HEAT

ELECTRIC HEAT

HUMIDISTAT

WATER ISOLATION VALVE

3RD STAGE HEAT (W1)

NOT USED

Deluxe Controls with

-all Heat Pump Units without Reheat

using X13511090010 (T8511)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1TB2

24 VAC (R)

FAN (G)

COMPRESSOR 1 (Y1) & WATER ISOLATION VA

COMPRESSOR 2 (Y2)

REVERSING VALVE (0) & HUMIDISTAT

24 VAC COMMON (C) & WATER ISOLATION VA

COMPRESSOR DISABLE

COMPRESSOR DISABLE

ALARM

ALARM

ELECTRIC HEAT

ELECTRIC HEAT

HUMIDISTAT

NOT USED

3RD STAGE HEAT (W3)

NOT USED

Deluxe Controls with

-all Heat Pump Units without Reheat

using X13511091010/X13511092010 (T7300)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1TB2

24 VAC (R)

FAN (G)

COMPRESSOR 1 (Y1) & WATER ISOLATION VA

COMPRESSOR 2 (Y2)

REVERSING VALVE (0) & HUMIDISTAT

24 VAC COMMON (X) & WATER ISOLATION VA

COMPRESSOR DISABLE

COMPRESSOR DISABLE

ALARM

ALARM

ELECTRIC HEAT

ELECTRIC HEAT

HUMIDISTAT

NOT USED

3RD STAGE HEAT (W1)

NOT USED

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the power can not be

inadvertently energized. Failure to disconnect power

before servicing could result in death or serious injury.

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow codes could result in death or serious injury.

Figure 60. Service access panel

Loading...

Loading...