Unit Start Up

130 RT-SVX36K-EN

Evaporative Condenser Startup

Important: Water treatment by a qualified water

treatment expert is required to ensure

proper equipment life and product

performance. Dolphin Water Care is an

option offered byTrane that is NOT a

substitute for regular water treatment by a

qualified water treatment professional. If a

water treatment system is not operating on

the unit, do not proceed.

Startup for evaporative and air-cooled condensers is

initially the same. In addition, the following is required for

evaporative condensers prior to startup:

• All water and drain connections must be checked and

verified

• Evaporative condensers will ship with a fan support

bracket to reduce damage caused by vibration during

shipment.The shipping support brackets must be

removed prior to unit startup. See “To remove

shipping brackets,” p. 130 and Figure 85, p. 131 for

removal instructions.

• Verify that inlet water pressure is 35-60 PSIG, dynamic

pressure (measured with the valve open)

• Verify that drain valve is set to “drain during power

loss” or “hold during power loss” per job specification

• Upon a call for cooling, the sump will fill with water.

Verify that the sump fills to a level within the slot on the

max float bracket as shown in Figure 86, p. 131.

To remove shipping brackets

Important: Remove fan shipping brackets before

startup. Failure to remove brackets could

result in fan damage.

Evaporative condensers are shipped with fan shipping

brackets to reduce damage caused by vibration during

shipment.The fan shipping brackets must be removed

prior to unit startup.

To remove the shipping brackets start from the side

opposite to the drain actuator:

1. Loosen the screw for the bracket that holds the inlet

louvers below the door side.

2. Remove inlet louvers and set to the side.

Note: Service technician may need to step on the

horizontal surface of FRP coated base.

Step with care.

3. Unscrew the bolt in the middle of the door. Keep the

bolt in a safe place.

4. Lift one door with handle until it touches the top.

Swivel bottom of door to remove it from the door

opening and set it to the side.

5. Slide and remove the middle mist eliminator section

so that the shipping bracket is visible.

6. Use screw gun to unscrew the two screws that hold the

fan shipping bracket.The bracket should drop down

but still remain engaged with a hook on the bracket.

7. Go to the other side of the unit and follow the

procedure for inlet louver and door removal

(see steps1-6).

8. Hold the bracket with one hand and remove remaining

two screws.

9. Remove the bracket and all the removed screws from

the unit.

Important: Make sure there are no screws remaining in

the coil area.

10. Reinstall inlet louvers, mist eliminators and louvers.

11. Check that the direction of arrow on the inlet louver is

correct.

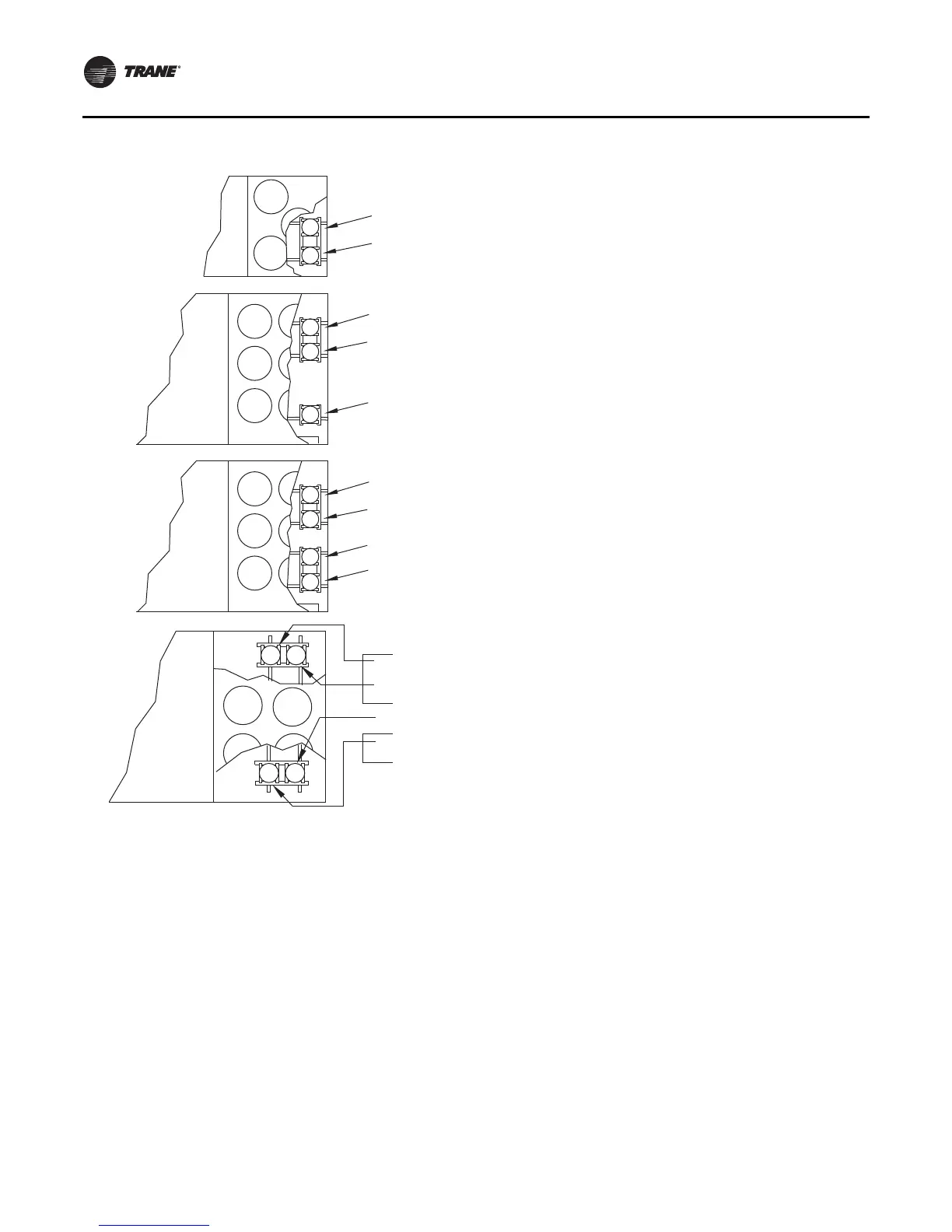

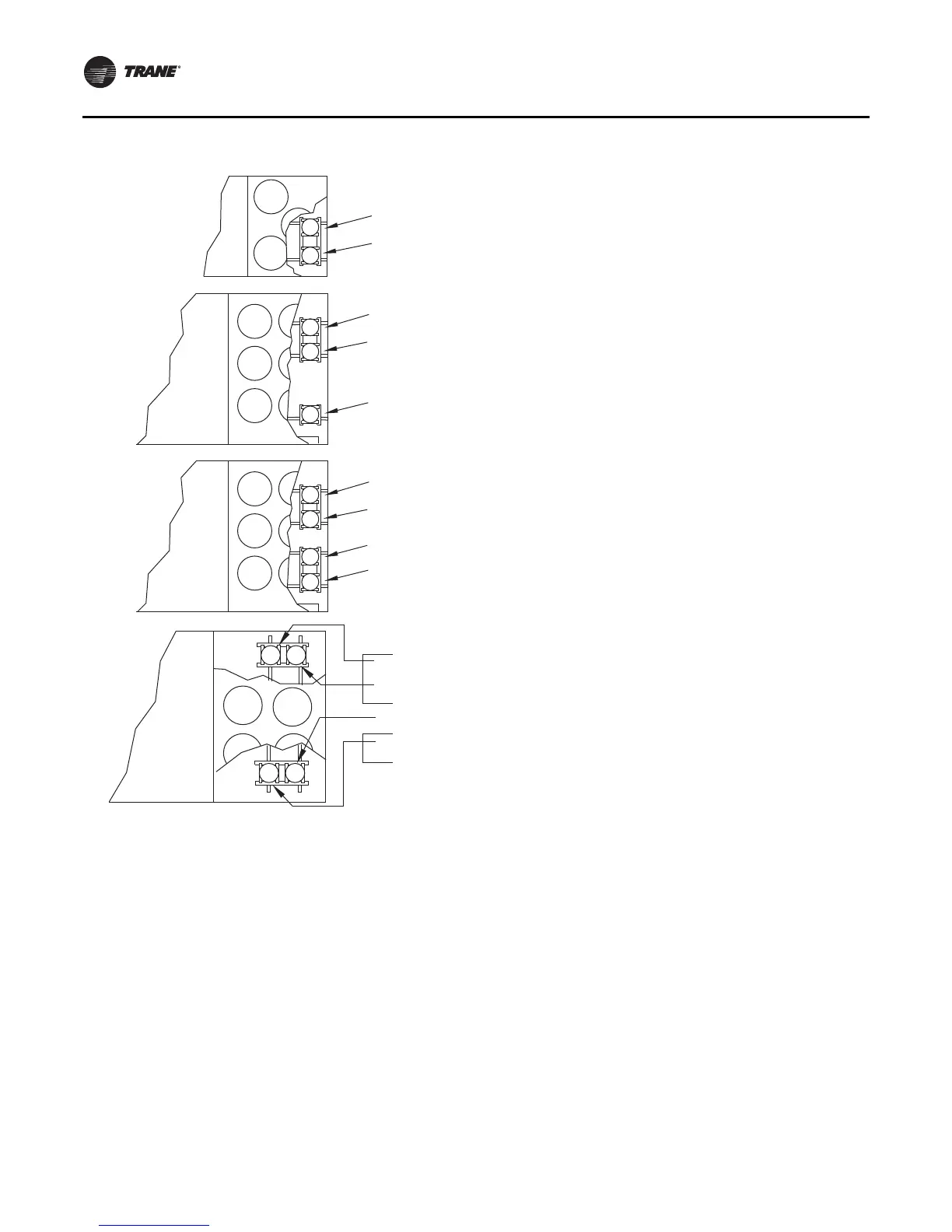

Figure 84. Compressor locations

20-36 Ton

40-89 Ton

Compressor A

HI Designator “K10”

Compressor B

HI Designator “K11”

Compressor 2B

HI Designator “K4”

Compressor 2A

HI Designator “K3”

Compressor 1A

HI Designator “K11”

Compressor 1B

HI Designator “K12”

40-70T

variable speed

compressor

Compressor 2B

HI Designator “K4”

Compressor 2A

HI Designator “K3”

Compressor 1A

HI Designator “K11”

Compressor 1B

HI Designator “K12”

Compressor 2B

HI Designator “K4”

Compressor 2A

HI Designator “K3”

Compressor 1A

HI Designator “K11”

90-130 Ton

Loading...

Loading...