Installation

52 RT-SVX36K-EN

4. Install a “Gate” type valve in the supply branch line as

close as possible to the hot water main and upstream

of any other device or takeoff.

5. Install a “Gate” type valve in the return branch line as

close as possible to the return main and down stream

of any other device.

6. Install a strainer in the hot water supply branch as

shown in Figure 35 and Figure 44.

7. Install the 3-way valve in an upright position, piped for

valve seating against the flow. Ensure that the valve's

location lends itself to serviceability.

8. TheType “W” hot water coil used in SLHL units is self-

venting only when the tube water velocity exceeds 1.5

feet per second (fps). If the tube velocity is less than 1.5

feet per second, either:

a. install an automatic air vent at the top of the return

header, using the tapped pipe connection;

or,

b. vent the coil from the top of the return header down

to the return piping. At the vent connection, size the

return piping to provide sufficient water velocity.

9. Install a“Globe” type valve in the Bypass line as shown

in Figure 35, p. 53 and Figure 44, p. 72.

Steam Heat Units (SSH_)

Steam heating coils are factory installed inside the heater

section of the unit.The coils are pitched, within the units,

to provide the proper condensate flow from the coil.To

maintain the designed degree of pitch for the coil, the unit

must be level.

Once the unit is set into place, the steam piping and the

factory provided two way modulating valve must be

installed.The valve can be installed inside the heater

section or near the unit. If the valve is installed in a remote

location, use field supplied wiring to extend the control

wires from the heater section to the valve.Two access

holes are provided in the unit base as illustrated in

Figure 15, p. 29.

Following the guidelines listed below will enhance both

the installation and operation of the “wet heat” system.

Figure 37, p. 54 and Figure 38, p. 54 illustrate the

recommended piping configurations for the steam coil.

Table 27, p. 62 lists the coil connection sizes.

Note: The valve actuators are not waterproof. Failure to

protect the valve from moisture may result in the

loss of heating control.

1. Support all field-installed piping independently from

the heating coil.

2. Use swing joints or flexible connectors adjacent to the

heating coil. (These devices will absorb the strains of

expansion and contraction.)

3. Install the 2-way valve in an upright position. Ensure

that the valve's location lends itself to serviceability.

4. Pitch the supply and return steam piping downward 1"

per 10' of run in the direction of flow.

5. All return lines and fittings must be equal to the

diameter of the “outlet” connection on the steam

coil(s). If the steam trap connection is smaller that the

coil “outlet” diameter, reduce the pipe size between

the strainer and the steam trap connections only.

6. Install a 1/2” 15 degree swing-check vacuum breaker at

the top of the return coil header using the tapped pipe

connection. Position the vacuum breaker as close to

the coil as possible.

Note: Vacuum breakers should have extended lines from

the vent ports to the atmosphere or connect each

vent line to the return pipe on the discharge side of

the steam traps.

7. Install a “Gate” type valve in the supply branch line as

close as possible to the steam main and upstream of

any other device.

8. Install a “Gate” type valve in the return branch line as

close as possible to the condensate return main and

downstream of any other device.

9. Install a strainer as close as possible to the inlet of the

control valve and steam trap(s).

10. Steam trap selection should be based on the

maximum possible condensate flow and the

recommended load factors.

11. Install a Float-and-Thermostatic (FT) type trap to

maintain proper flow.They provide gravity drains and

continuous discharge operation. FT type traps are

required if the system includes either;

a. an atmospheric pressure/gravity condensate

return;

or,

b. a potentially low pressure steam supply.

12. Position the outlet or discharge port of the steam trap

at least 12" below the outlet connection on the coil(s).

This will provide adequate hydrostatic head pressure

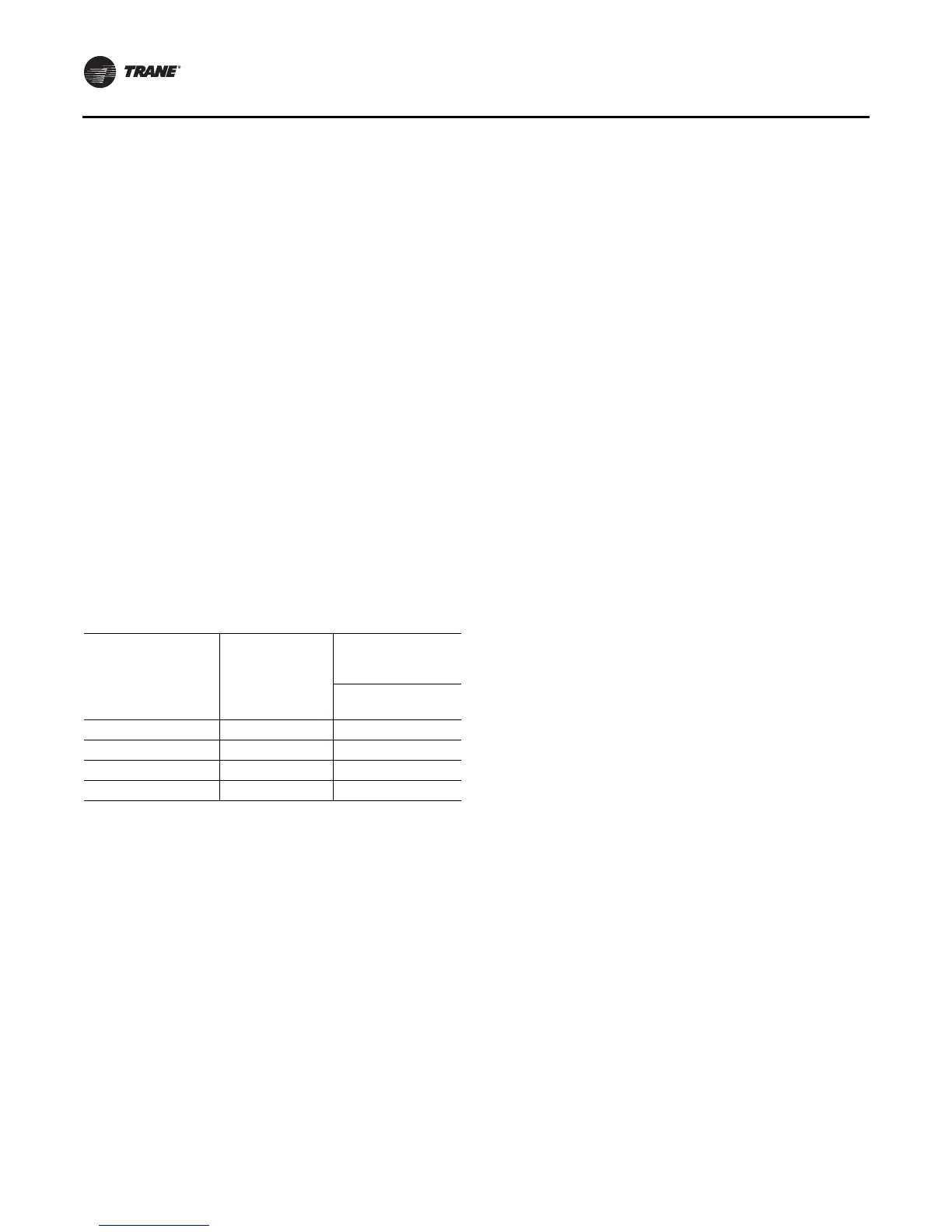

Table 21. Connection sizes for hot water and steam

coil

(a)

(a)Type W coils-with center offset headers-are used in SLH* units; Type

NS coils are used in SSH* units

Coil Connections

(diameter in

inches)

Unit Model and Size

Heat Section

Capacity

(b)

(b)See Digit 9 of the unit model number to determine the heating capacity.

Supply Return

SLH*-20 to 130 High or Low Heat 2-1/2" 2-1/2"

SSHL-20 to 36 High or Low Heat 3" 1-1/4"

SSHL-40 to 89

(c)

(c) SSH* - 40 to 89 Ton units have multiple headers.

High Heat Low Heat 3" 1-1/2"

SSHK-90 to 130 Low Heat(c) 1-1/2” 1”

Loading...

Loading...