Unit Start Up

RT-SVX36K-EN 127

Use Table 58, p. 127 to select the appropriate crank arm

hole configuration based on the;

a. specific unit

b. operating CFM

c. and return static pressure.

Compressor Start-Up (All Systems)

1. Ensure that the “System” selection switch at the

remote panel is in the “Off” position.

2. Before closing the disconnect switch, ensure that the

compressor discharge service valve and the liquid line

service valve for each circuit is back seated.

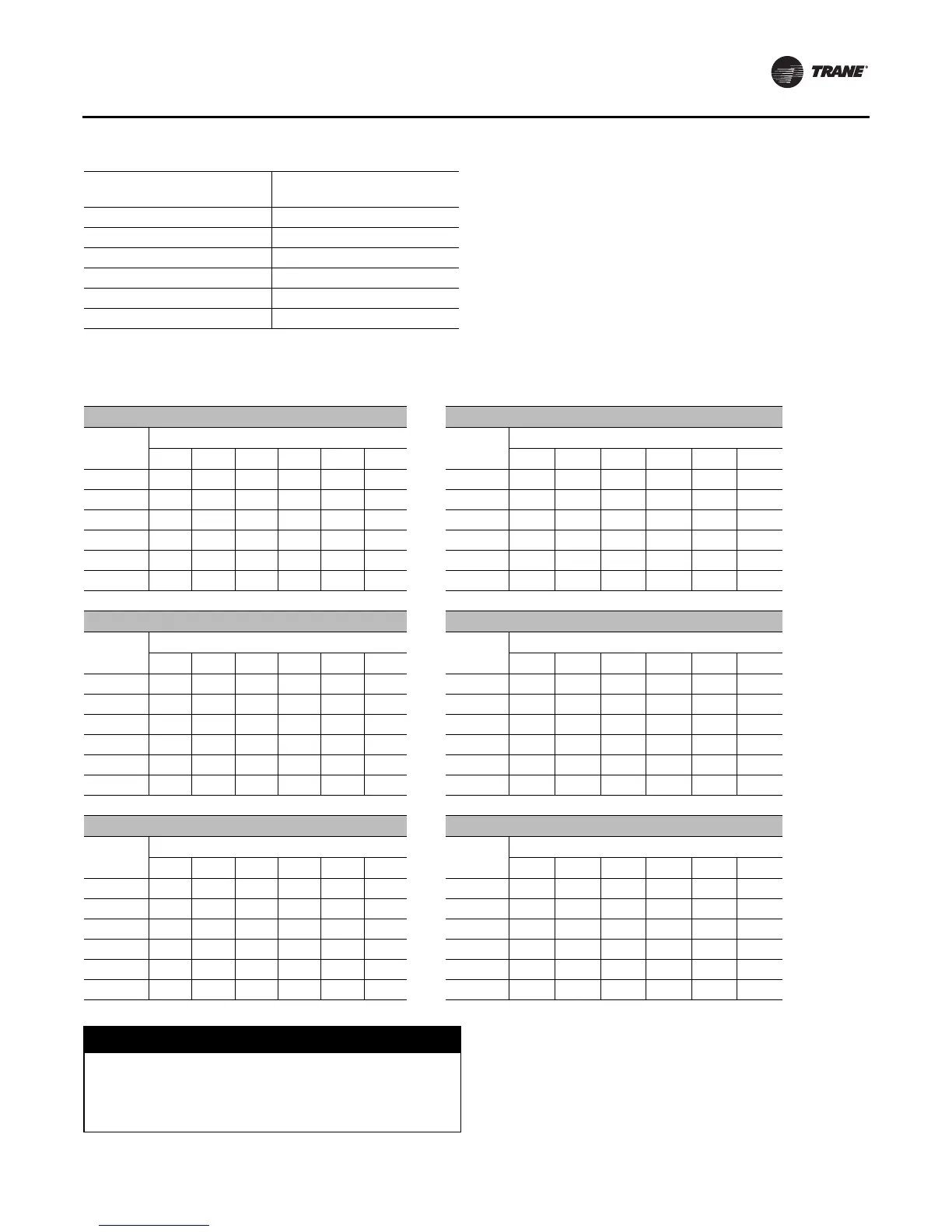

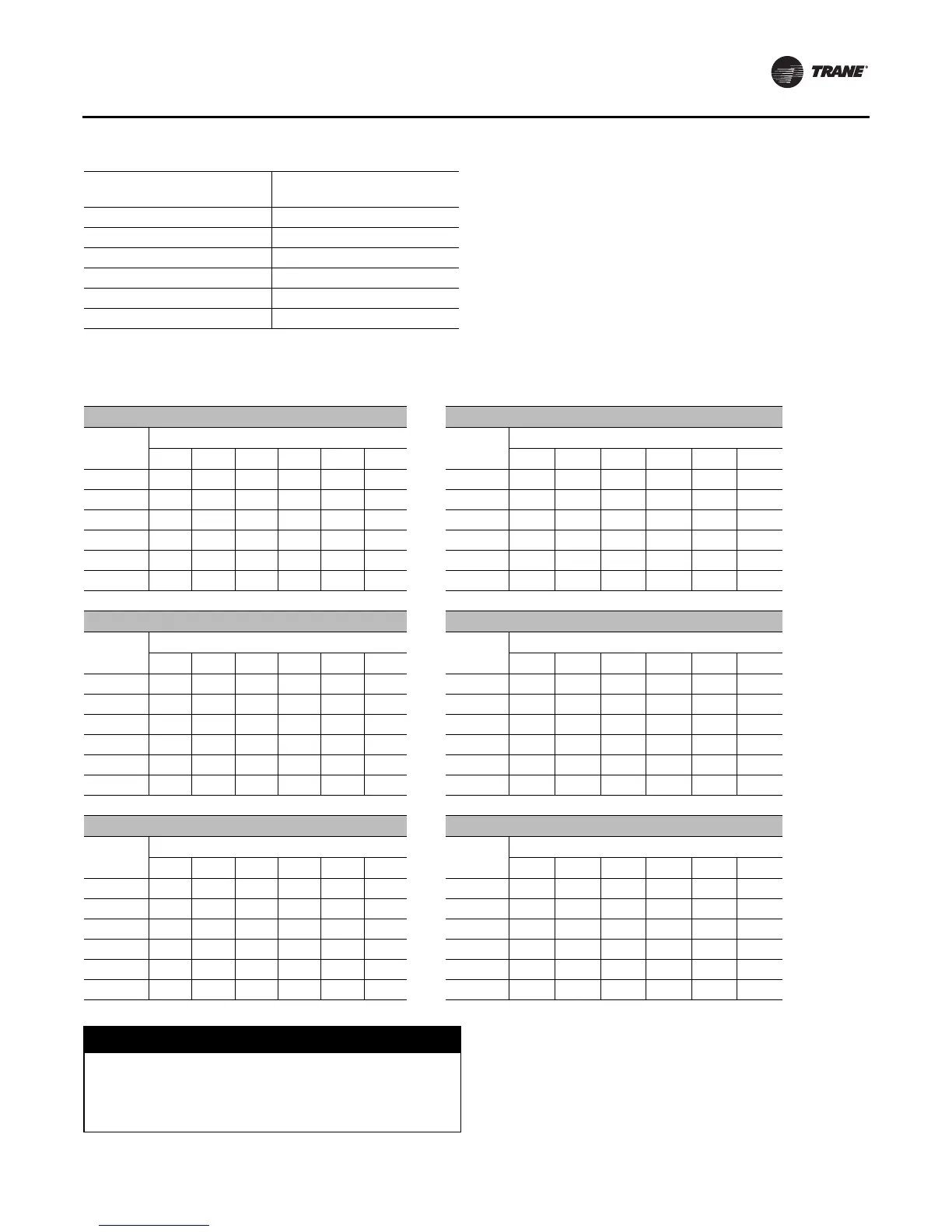

Table 57. F/A Damper travel adjustment

Position of Connecting Rod

(Figure 81, p. 117)

Damper Crank Arm Hole

Configuration

Position #1 2 - 3

Position #2 2 - 4

Position #3 2 - 5

Position #4 2 - 6

Position #5 1 - 8

Position #6 1 - 7

Note: As shipped from the factory, the connect rod is installed in Position

#1.

Table 58. Outside air damper pressure drop (inches w.c.) — Air-Cooled and Evaporative Condensing

(20, 25 Ton and 24, 29 Ton) Units (50, 55 and 59 Ton) Units

CFM

Damper Position

CFM

Damper Position

#1 #2 #3 #4 #5 #6 #1 #2 #3 #4 #5 #6

4000 0.03 0.04 0.06 0.13 0.16 0.33 10000 0.03 0.04 0.09 0.18 0.23 0.55

6000 0.03 0.04 0.10 0.20 0.30 0.90 14000 0.09 0.12 0.20 0.35 0.50 1.36

8000 0.19 0.21 0.32 0.52 0.75 1.75 18000 0.31 0.36 0.50 0.79 1.10 -

9000 0.30 0.35 0.48 0.76 1.08 2.40 20000 0.45 0.51 0.70 1.05 1.57 -

10000 0.45 0.51 0.70 1.05 1.57 - 22000 0.58 0.66 0.75 1.30 1.95 -

11000 0.62 0.71 0.95 1.42 2.15 - 24000 0.75 0.88 1.10 1.75 2.50 -

(30, 36 Ton) Units (60, 70, 75 Ton and 73, 80, 89 Ton) Units

CFM

Damper Position

CFM

Damper Position

#1 #2 #3 #4 #5 #6 #1 #2 #3 #4 #5 #6

6000 0.03 0.04 0.07 0.15 0.20 0.43 14000 0.03 0.04 0.12 0.25 0.35 1.05

8000 0.03 0.05 0.11 0.21 0.30 0.90 18000 0.19 0.21 0.32 0.52 0.75 1.75

10000 0.15 0.19 0.26 0.43 0.62 1.50 22000 0.45 0.51 0.70 1.05 1.57 -

11000 0.20 0.25 0.37 0.60 0.85 1.85 26000 0.70 0.80 1.02 1.58 2.30 -

12000 0.31 0.36 0.50 0.79 1.10 2.40 28000 0.88 1.03 1.30 2.20 - -

13000 0.42 0.48 0.62 0.97 1.42 - 30000 1.05 1.22 1.55 2.65 - -

(40, 48 Ton) Units (90 - 130 Ton) Units

CFM

Damper Position

CFM

Damper Position

#1 #2 #3 #4 #5 #6 #1 #2 #3 #4 #5 #6

8000 0.03 0.04 0.08 0.16 0.21 0.52 27000 0.31 0.36 0.50 0.79 1.10 2.40

10000 0.03 0.05 0.11 0.21 0.30 0.90 32000 0.55 0.64 0.72 1.25 1.88 -

12000 0.10 0.13 0.21 0.38 0.55 1.40 36000 0.75 0.88 1.10 1.75 2.50 -

14000 0.20 0.25 0.37 0.60 0.85 1.85 40000 1.00 1.18 1.50 2.50 - -

16000 0.41 0.46 0.60 0.94 1.38 - 43000 1.20 1.42 1.92 - - -

18000 0.56 0.65 0.74 1.28 1.92 - 46000 1.40 1.58 2.29 - - -

NOTICE:

Compressors Failure!

Unit must be powered and crankcase heaters energized

at least 8 hours BEFORE compressors are started. This

will protect the compressors from premature failure.

Loading...

Loading...