Installation

RT-SVX36K-EN 37

Note: To assure proper condensate flow during

operation, the unit (and curb) must be as level as

possible.The maximum slope allowable for

rooftop unit applications, excluding SSH_'s, is 4"

end-to-end and 2" side-to-side. Units with steam

coils (SSH_'s) must be set level!

If the unit is elevated, a field constructed catwalk around

the unit is strongly recommended to provide easy access

for unit maintenance and service.

Recommendations for installing the SupplyAir and Return

Air ductwork joining the roof curb are included in the curb

instruction booklet. Curb ductwork must be fabricated and

installed by the installing contractor before the unit is set

into place.

Note: For sound consideration, cut only the holes in the

roof deck for the ductwork penetrations. Do not cut

out the entire roof deck within the curb perimeter.

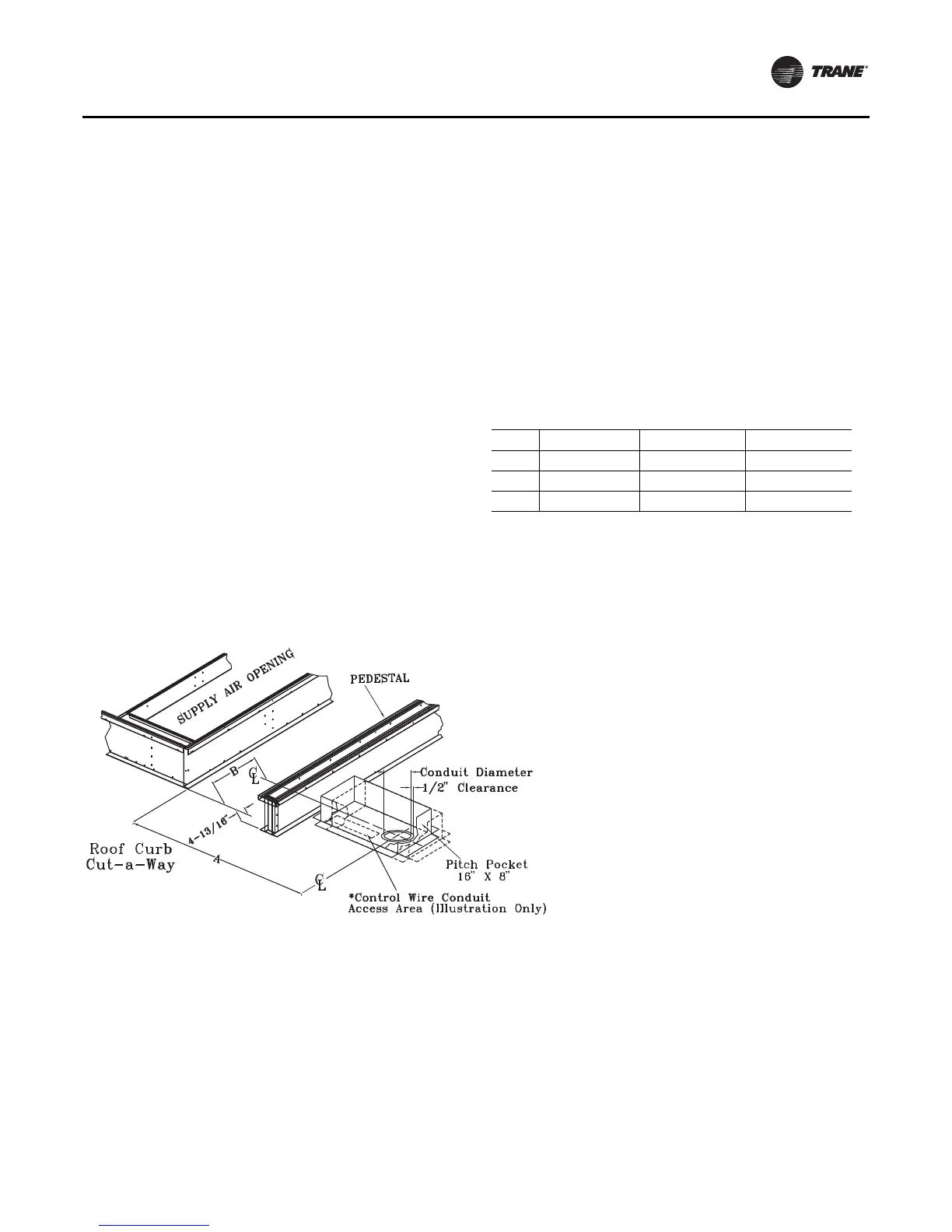

Pitch Pocket Location

The location of the main supply power entry for S_HL 20

through 89Ton rooftop units is located at the bottom right-

hand corner of the control panel.

Figure 14 and Figure 15 illustrate the location for the

electrical entrance through the base in order to enter the

control panel. If the power supply conduit penetrates the

building’s roof beneath this opening, it is recommended

that a pitch pocket be installed before the unit is placed

onto the roof curb.

The center line dimensions shown in the illustration below

indicates the center line of the electrical access hole in the

unit base when it is positioned on the curb, ±3/8 inch.The

actual diameter of the hole in the roof should be at least 1/

2 inch larger than the diameter of the conduit penetrating

the roof.This will allow for the clearance variable between

the roof curb rail and the unit base rail illustrated in

Figure 19.

The pitch pocket dimensions listed are recommended to

enhance the application of roofing pitch after the unit is set

into place.The pitch pocket may need to be shifted as

illustrated to prevent interference with the curb pedestal.

If a Trane Curb Accessory Kit is Not Used:

a. The ductwork can be attached directly to the

factory-provided flanges around the unit’s supply

and return air openings. Be sure to use flexible duct

connections at the unit.

b. For “built-up” curbs supplied by others, gaskets

must be installed around the curb perimeter flange

and the supply and return air opening flanges.

Notes:

• If a “built-up” curb is provided by others, keep in mind

that these commercial rooftop units do not have base

pans in the condenser section.

• If this is a REPLACEMENT UNIT keep in mind that the

CURRENT DESIGN commercial rooftop units do not

have base pans in the condenser section.

• Trane roof curbs are recommended. If using a non-

Trane roof curb with right-angle return airflow

approaches to a return fan inlet, a rigid, solid flow

baffle wall should be installed across the full width of

the roof curb return airflow path in the position shown

in Figure 20, p. 38 to reduce potential airflow

Table 16. Pitch pocket dimensions

Unit Tonnage “A” Dimension "B" Dimension

S*HL 20, 25 & 30 4' 5-9/16" 5-9/16"

S*HL 24, 29, & 36 6' 9-11/16” 5-1/2”

S*HL 40 - 89 9' 5-11/16" 5-1/2"

* = All unit functions (SAHL, SEHL, SFHL, SSHL, SLHL and SXHL)

Notes: For design special evaporative-cooled condensing units, please

see the curb installers guide for proper pitch pocket locations.

Figure 19. Pitch pocket location

Loading...

Loading...