Unit Start Up

RT-SVX36K-EN 147

Thermostatic Expansion Valves

The reliability and performance of the refrigeration system

is heavily dependent upon proper expansion valve

adjustment.Therefore, the importance of maintaining the

proper superheat cannot be over emphasized. Expansion

valves are preset at the factory. In typical applications, field

adjustment should not be required unless the valves are

replaced or damaged.

On air-cooled units, the expansion valves shipped

installed were factory set to control between 14-18°F at the

ARI full load rating conditions (approximately 45°/125°F

saturated suction/discharge).

On evaporative condenser units, the expansion valves

shipped installed were factory set to control between 18-

22°F at the ARI full load rating conditions (approximately

45°/105°F saturated suction/discharge). At part load,

expect lower superheat. Systems operating with lower

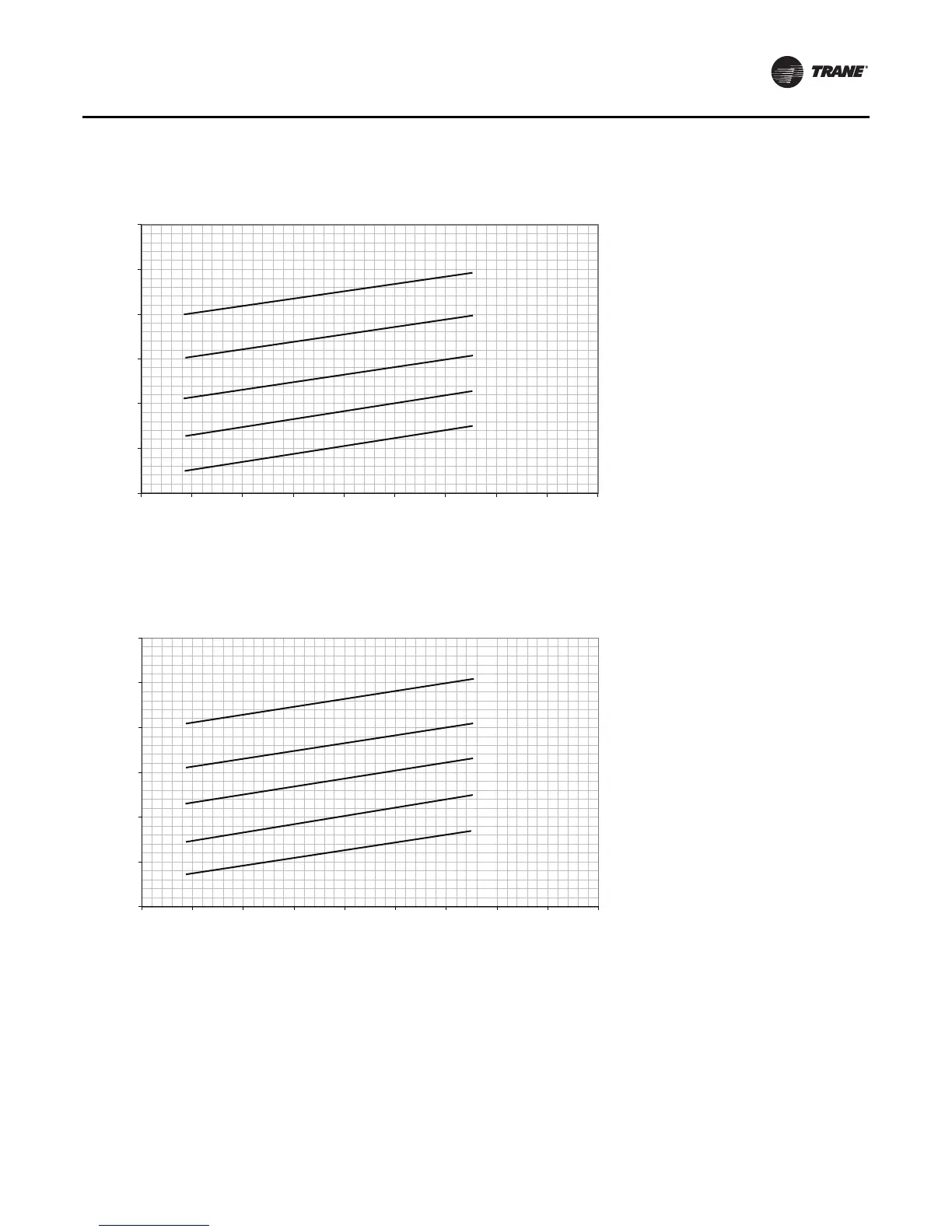

Figure 117. 115 ton high operating pressure curve (all compressors and condenser fans “On”)

COOLING CYCLE PRESSURE CURVE

105 Ton High Capacity

250

300

350

400

450

500

550

90 100 110 120 130 140 150 160 170 180

COOLING CYCLE PRESSURE CURVE

115 Ton Standard Capacity

95 °F Ambient

85 °F Ambient

65 °F Ambient

105 °F Ambient

250

300

350

400

450

500

550

90 100 110 120 130 140 150 160 170 180

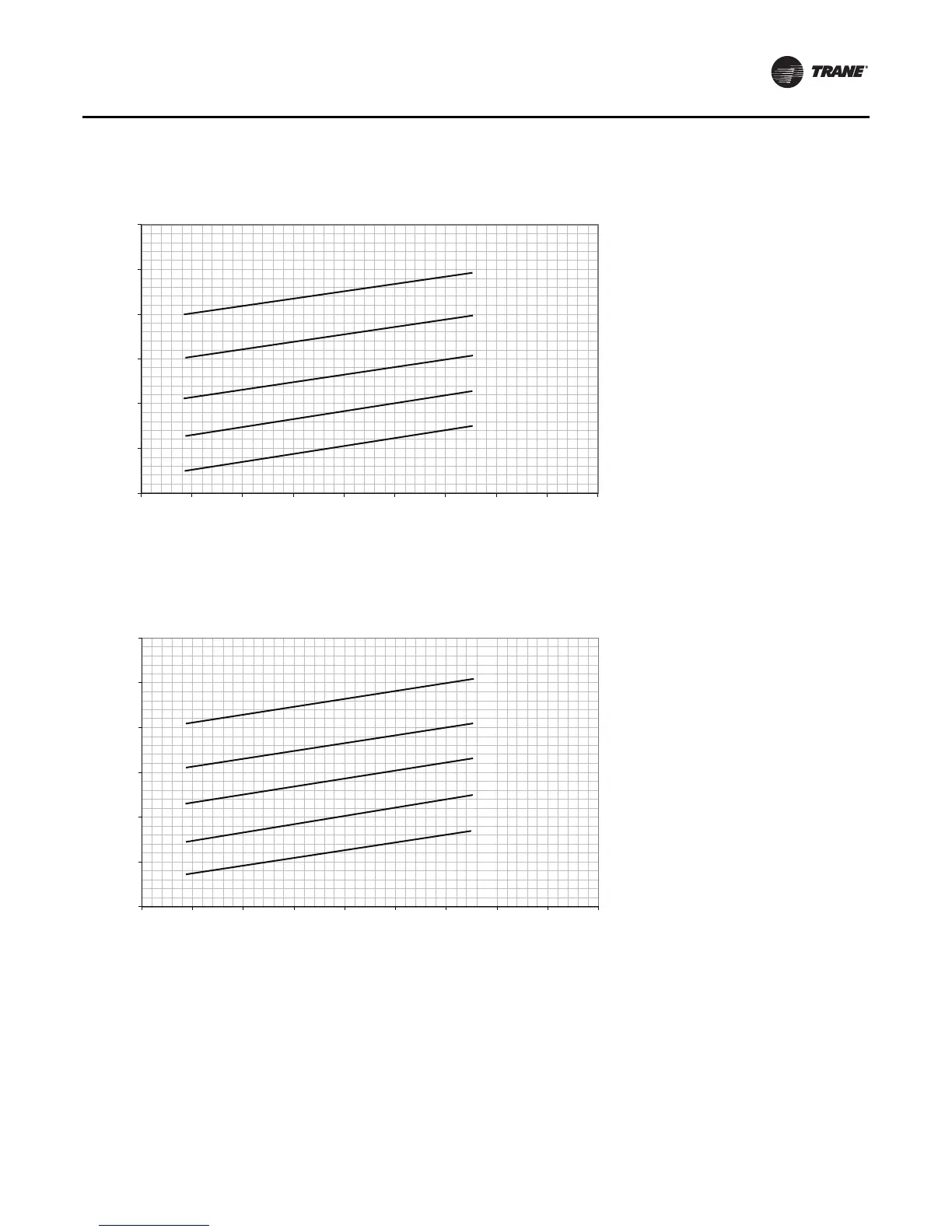

Figure 118. 130 ton high operating pressure curve (all compressors and condenser fans “On”)

COOLING CYCLE PRESSURE CURVE

105 Ton High Capacity

250

300

350

400

450

500

550

90 100 110 120 130 140 150 160 170 180

COOLING CYCLE PRESSURE CURVE

115 Ton Standard Capacity

250

300

350

400

450

500

550

90 100 110 120 130 140 150 160 170 180

COOLING CYCLE PRESSURE CURVE

130 Ton Standard Capacity

95 °F Ambient

85 °F Ambient

75 °F Ambient

65 °F Ambient

105 °F Ambient

250

300

350

400

450

500

550

90 100 110 120 130 140 150 160 170 180

Loading...

Loading...