Installation

RT-SVX36K-EN 51

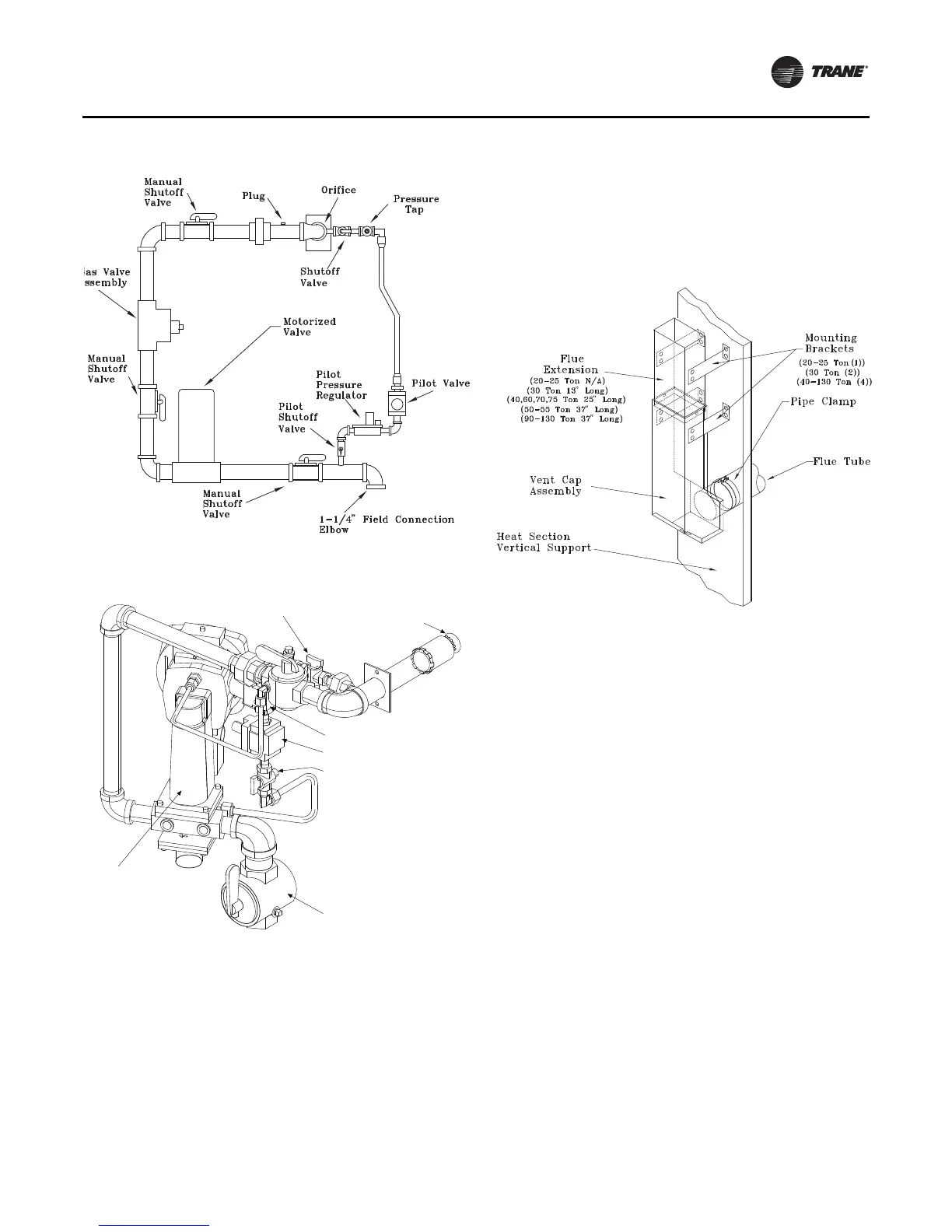

Flue Assembly Installation

1. Locate the flue assembly and the extension (refer to

Figure 34 for extension usage) in the ship with section

of the unit.

2. Install the flue extension onto the flue assembly as

shown in Figure 34.

3. Slide the pipe clamp onto the heater flue tube located

inside the heater compartment.

4. Insert the tube on the flue assembly into the hole

located in the vertical support for the heat section.

5. Butt both flue tube sections together and center the

pipe clamp over joint.

6. Using the pre-punch holes in the flue assembly,

extension, and the vertical support, install the

appropriate number of mounting brackets. Refer to

Figure 34 for details.

Hot Water Heat Units (SLH_)

Hot water heating coils are factory installed inside the

heater section of the unit. Once the unit is set into place,

the hot water piping and the factory provided three way

modulating valve must be installed.The valve can be

installed inside the heat section or near the unit. If the

valve is installed in a remote location, use field supplied

wiring to extend the control wires from the heater section

to the valve.Two access holes are provided in the unit base

as illustrated in Figure 15, p. 29.

Following the guidelines listed below will enhance both

the installation and operation of the “wet heat” system.

Figure 35, p. 53 and Figure 37, p. 54 illustrate the

recommended piping configuration for the hot water coil.

Table 27, p. 62 lists the coil connection sizes.

Note: The valve actuators are not waterproof. Failure to

protect the valve from moisture may result in the

loss of heating control.

1. Support all field-installed piping independently from

the heating coil.

2. Use swing joints or flexible connectors adjacent to the

heating coil. (These devices will absorb the strains of

expansion and contraction).

3. All return lines and fittings must be equal to the

diameter of the “outlet” connection on the hot water

coil.

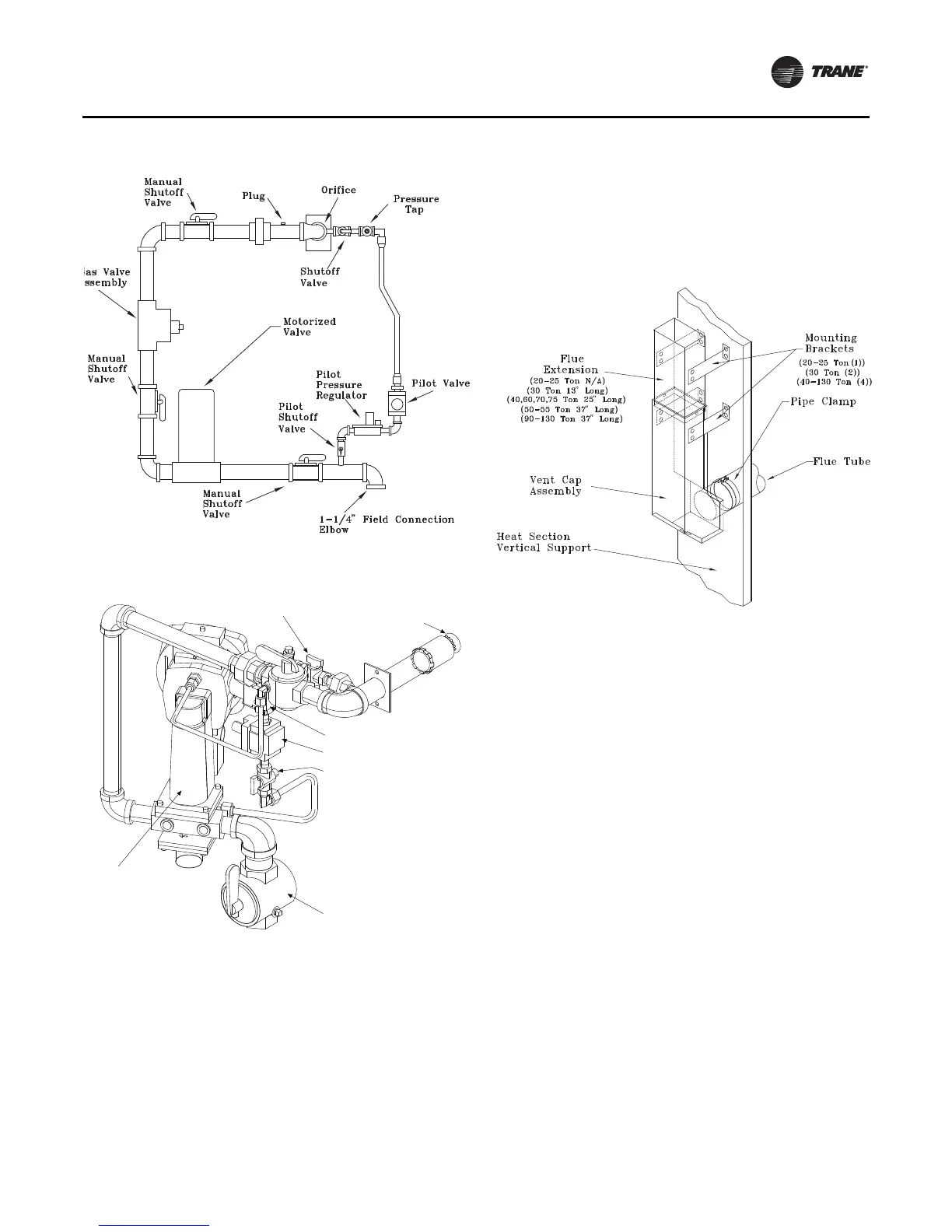

Figure 32. Unit gas trains (natural gas) 1000 MBH

Figure 33. Modulating 500 - 1000 MBH

Burner Nozzle

Pilot Shutoff Valve

Pilot Solenoid Valve

Pilot Regulator Valve

Pilot Shutoff Valve

Modulating Gas Valve

Shutoff Valve

Figure 34. Flue Assembly

Loading...

Loading...