Installation

50 RT-SVX36K-EN

Table 20. Gas heating capacity altitude correction factors

Altitude (Ft.)

Sea Level - 2000 2001 - 2500 2501 - 3500 3501 - 4500 4501 - 5500 5501 - 6500 6501 - 7500

Capacity

Multiplier

1.00 .92 .88 .84 .80 .76 .72

Note: Correction factors are per AGA Std. 221.30 - 1964, Part VI, 6.12. Local codes may supersede.

Notes:

1. If more than one unit is served by the same main gas supply, consider the total gas input (cubic feet/hr.) and the total length when determining the

appropriate gas pipe size.

2. Obtain the Specific Gravity and BTU/Cu.Ft. from the gas company.

3. The following example demonstrates the considerations necessary when determining the actual pipe size.

Example: A 40' pipe run is needed to connect a unit with a 500 MBH furnace to a natural gas supply having a rating of 1,000 BTU/Cu.Ft. and a specific gravity of 0.60

Cu.Ft/Hour = Furnace MBH Input

Gas BTU/Cu.Ft. X Multiplier (Table 23)

Cu.Ft/Hour = 500

4. Table 24 indicates that a 1-1/4” pipe is required.

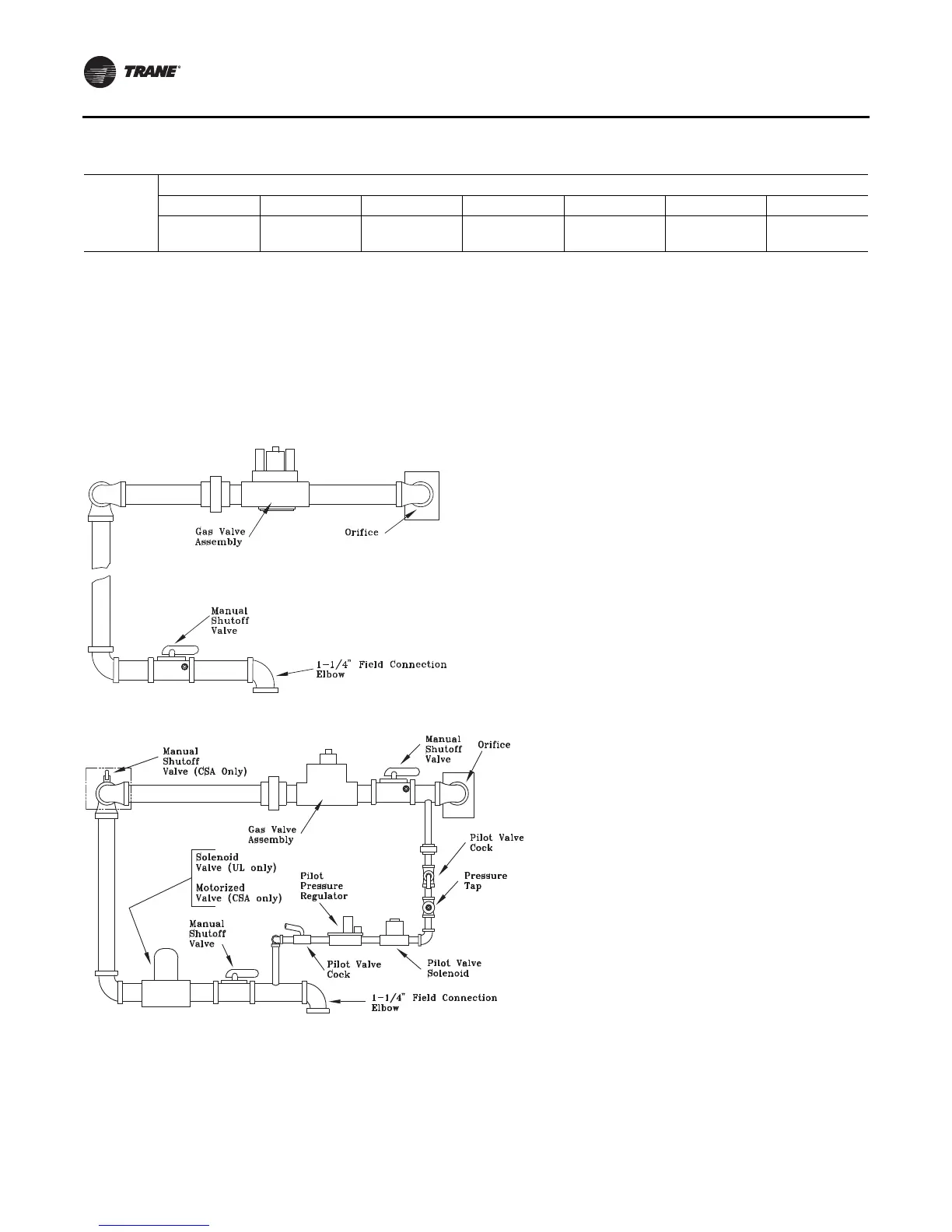

Figure 30. Unit gas trains (natural gas) 235, 350 MBH

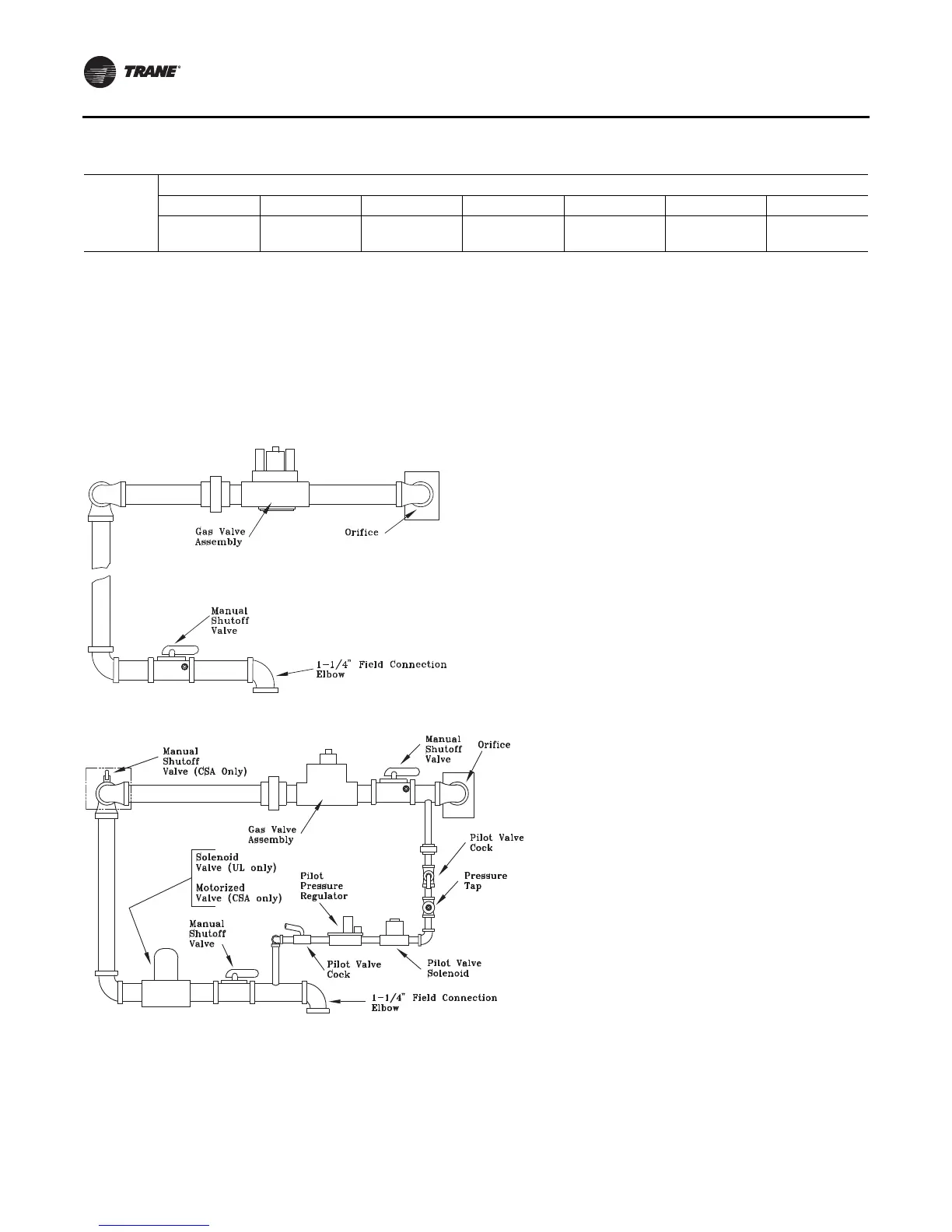

Figure 31. Unit gas trains (natural gas) 500, 850 MBH

Loading...

Loading...