Unit Start Up

148 RT-SVX36K-EN

superheat could cause serious compressor damage due to

refrigerant floodback.

Tables are based on outdoor ambient between 65° & 105°F,

relative humidity above 40 percent. Measuring the

operating pressures can be meaningless outside of these

ranges.

Measuring Superheat

1. Measure the suction pressure at the suction line gauge

access port located near the compressor.

2. Using a Refrigerant/Temperature chart, convert the

pressure reading to a corresponding saturated vapor

temperature.

3. Measure the suction line temperature as close to the

expansion valve bulb, as possible. Use a thermocouple

type probe for an accurate reading.

4. Subtract the saturated vapor temperature obtained in

step 2 from the actual suction line temperature

obtained in step 3.The difference between the two

temperatures is known as “superheat”.

When adjusting superheat, recheck the system subcooling

before shutting the system “Off”.

Note: If unit includes the modulating reheat

dehumidification control option, adjust superheat

only in the cooling mode of operation.

Charging by Subcooling

The outdoor ambient temperature must be between 65°

and 105° F and the relative humidity of the air entering the

evaporator must be above 40 percent. When the

temperatures are outside of these ranges, measuring the

operating pressures can be meaningless.

Do not attempt to charge the system with the low ambient

dampers and/or hot gas bypass operating (if applicable).

Disable the low ambient dampers in the “Open” position

(refer to the “Low Ambient Damper” section) and de-

energize the hot gas bypass valves before taking

performance measurements.

With the unit operating at “Full Circuit Capacity”,

acceptable subcooling range for air-cooled condenser

units is between 10°F to 18°F. For evaporative condenser

units, acceptable subcooling ranges is between 8°F to 14°F.

Note: If unit includes the modulating reheat

dehumidification control option, adjust subcooling

only in the cooling mode of operation.

Measuring Subcooling

1. At the liquid line service valve, measure the liquid line

pressure. Using an R-410A pressure/temperature

chart, convert the pressure reading into the

corresponding saturated temperature.

2. Measure the actual liquid line temperature as close to

the liquid line service valve as possible.To ensure an

accurate reading, clean the line thoroughly where the

temperature sensor will be attached.After securing the

sensor to the line, insulate the sensor and line to isolate

it from the ambient air. Use a thermocouple type probe

for an accurate reading.

3. Determine the system subcooling by subtracting the

actual liquid line temperature (measured in step 2)

from the saturated liquid temperature (converted in

step 1).

Low Ambient Dampers

Operation

Low Ambient Dampers are available as a factory installed

option on 20 - 75Ton units or can be field-installed.

Dampers are used to extend the operation of these units

from the standard operational temperatures to a

minimum of 0° F without hot gas bypass or 10° F with hot

gas bypass. (These values apply when wind speed across

the condenser coil is less than 5 m.p.h. If typical wind

speeds are higher than 5 m.p.h., a wind screen around the

unit may be required.) By restricting the airflow across the

condenser coils, saturated condensing temperatures can

be maintained as the ambient temperatures change.

The low ambient modulating output(s) on the compressor

module controls the low ambient damper actuator for

each refrigerant circuit in response to saturated

condensing temperature.

When the head pressure control has staged up to fan stage

2 or 3, the modulating output (0 to 10VDC) will be at 100%

(10VDC). When the head pressure control is at fan stage 1,

the modulating output will control the saturated

condensing temperature to within the programmable

“condensing temperature low ambient control point”.

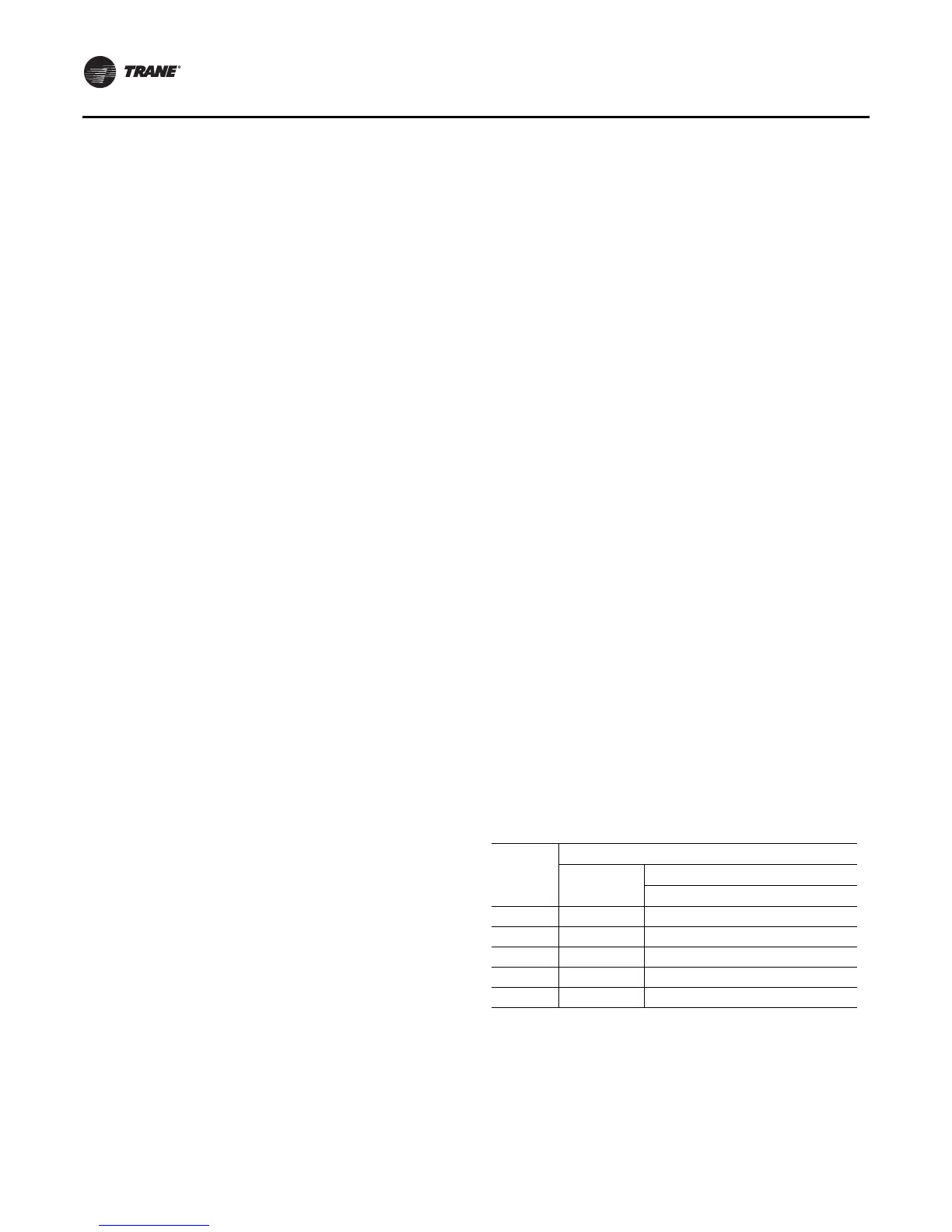

The followingTable gives the minimum starting

temperatures for both “Standard” & “Low” Ambient

units. Do not start the unit in the cooling mode if the

ambient temperature is below the recommended

operating temperatures.

Damper Installation

When a unit is ordered with the low ambient option (i.e.,

Digit 19 is a “1” in the model number), a damper is factory

Table 60. Minimum starting temperatures for air-cooled

units

(a)

(a)Minimum starting temperatures for Evaporative Condenser units is

40

°F without a sump heater and 10°F with a sump heater.

Unit Size

Minimum Starting Ambient

(b)

(b)Min. starting ambients in °F and is based on unit operating at min.

step of

unloading & 5 mph wind across condenser.

Low Ambient

Standard

(c)

(c) With or Without HGBP

with HGBP without HGBP

20 & 40 55° 10° 0°

25 & 30 50° 10° 0°

50, 55 35° 10° 0°

60 30° 10° 0°

70-130 45° 10° 0°

Loading...

Loading...