S9V2-SVX001-1B-EN

43

4. Hold the pipe in the fitting for 30 seconds to prevent

tapered socket from pushing the pipe out of the

fitting.

5. Wipe all excess cement from the joint with a rag.

Allow 15 minutes before handling. Cure time varies

according to fit, temperature and humidity.

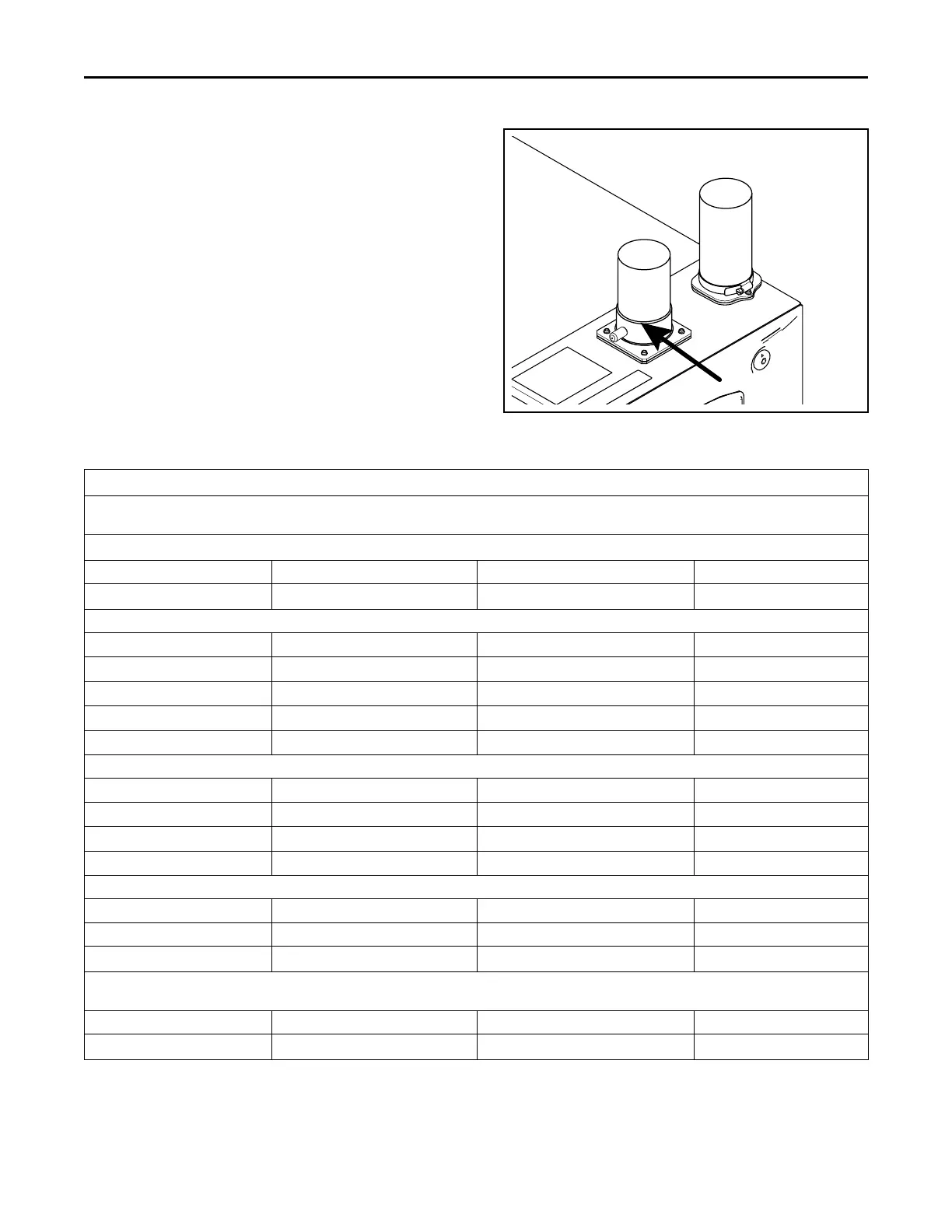

Connection of the pipe and collar of the combustion air

inlet should just be a friction fit. It is recommended that

the inlet air joint be sealed with RTV type sealant to

allow the joint to be separated for possible future

service. The inlet and vent pipes must be properly

supported throughout the entire length.

NNoottee:: Follow venting instructions carefully when using

PVC cement.

IImmppoorrttaanntt:: All joints must be water tight. Flue

condensate is somewhat acidic, and leaks

can cause equipment damage.

Seal INLET AIR PIPE

with RTV sealant

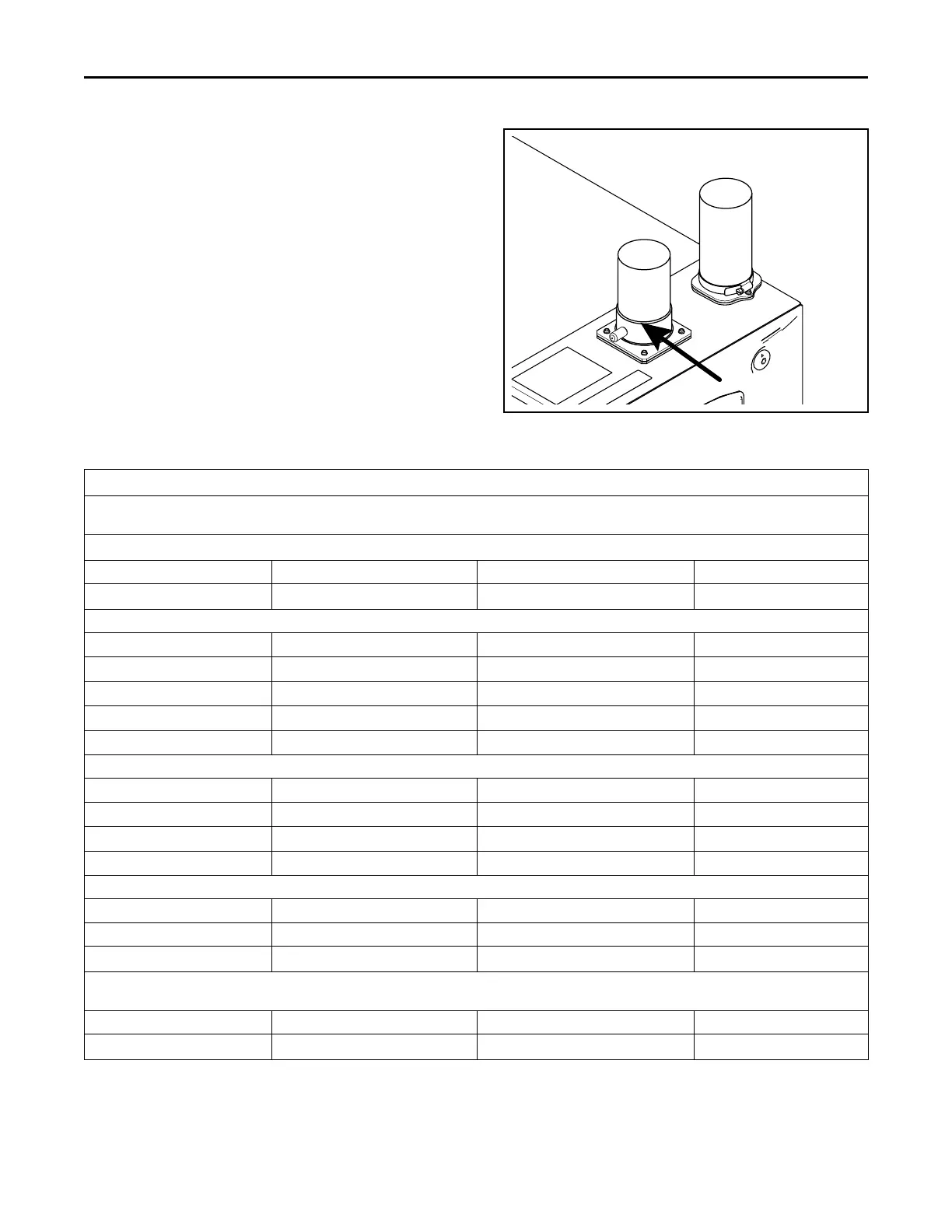

Approved Vent Pipe Materials

PVC Vent Fitting Material

These fittings are available from your Gas Furnace Distributors.

ANSI/UL 1738 APPROVED VENT PIPE MATERIAL

ASTM STANDARD PIPE TYPE ALLOWABLE TEMPERATURE °F MARKING

N/A N/A

158 UL 1738

PVC

ASTM STANDARD PIPE TYPE ALLOWABLE TEMPERATURE °F MARKING

F891

CELLULAR CORE

(a)

158 ASTM F891

D2665 DWV PIPE 158 ASTM D2665

D1785

SCH 40, 80, 120

158 ASTM 1785

D2241 SDR SERIES 158 ASTM D2241

CPVC

ASTM STANDARD PIPE TYPE ALLOWABLE TEMPERATURE °F MARKING

D2846 CPVC 41 212 ASTM D2846

F441

SCH 40, 80

212 ASTM F441

F442 SDR SERIES 212 ASTM F442

ABS

ASTM STANDARD PIPE TYPE ALLOWABLE TEMPERATURE °F MARKING

D2661 SCH 40 DWV 180 ASTM D2661

F628

SCH 40 DWV CELLULAR CORE

(a)

180 ASTM F628

PolyPro® by DuraVent , Z-Dens by Novaflex Group, Innoflue® by Centrotherm, System 1738 by IPEX, ECCO™ polypropylene venting system,

and PolyFlue™ polypropylene venting systems.

ASTM STANDARD PIPE TYPE ALLOWABLE TEMPERATURE °F MARKING

N/A N/A

230 ULC-S636

(a)

Beginning March 1, 2024, PVC Cellular Core and ABS Cellular Core vent materials are not approved.

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Loading...

Loading...