4.1 Description of operation

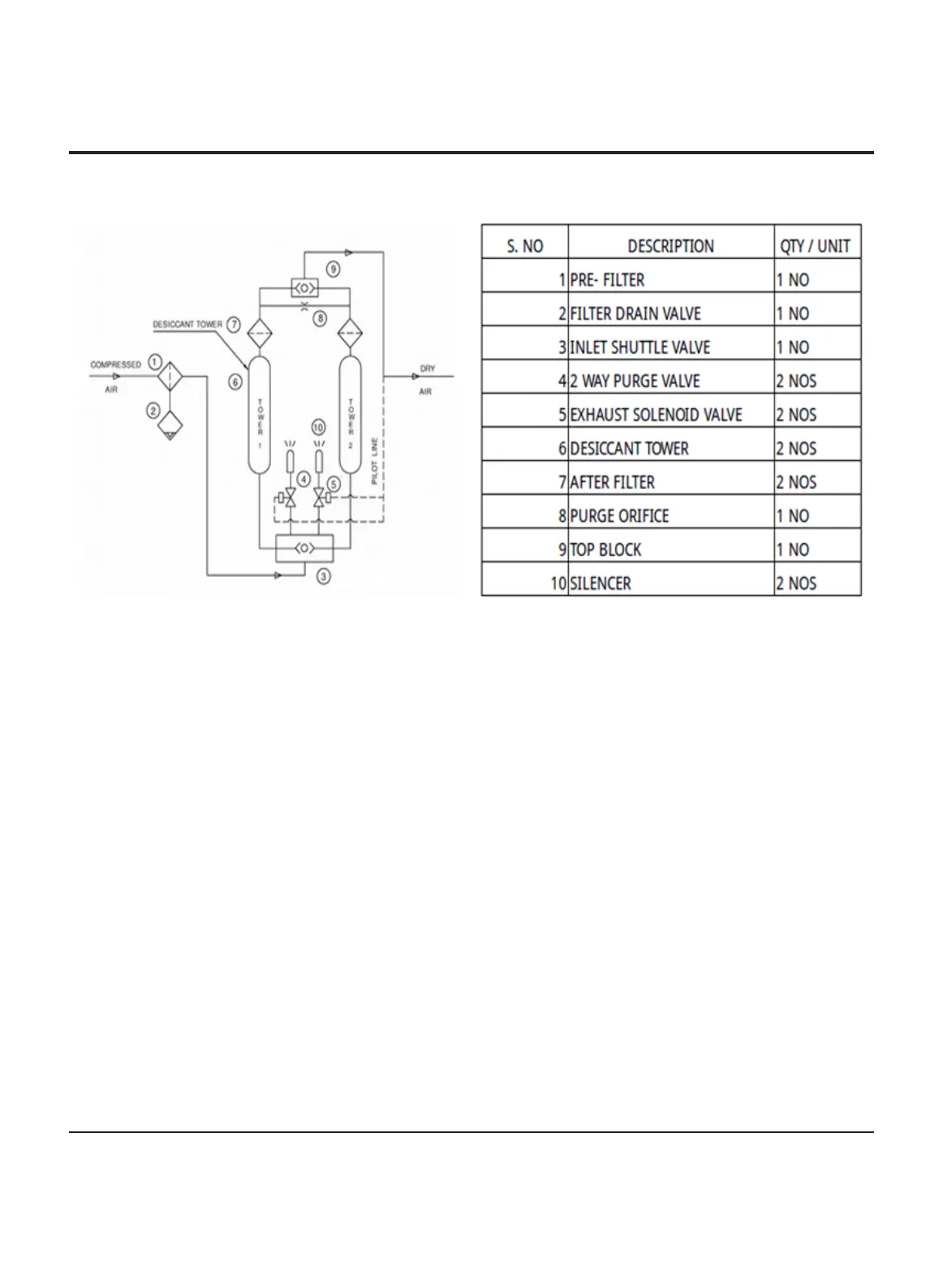

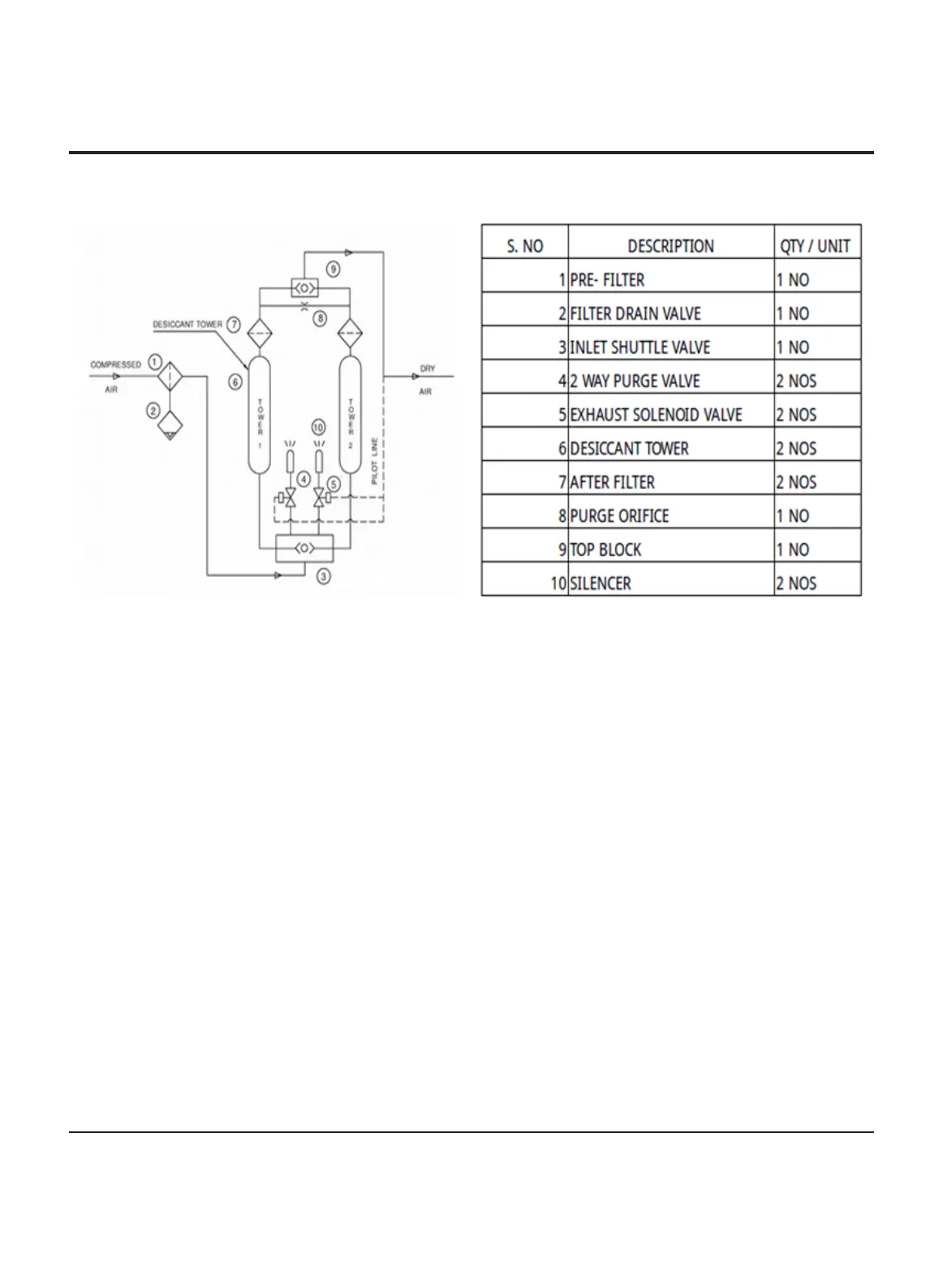

Figure 3. Schematic of Dryspell Plus dryer

Compressed air containing moisture and oil droplets enters the pre-filter. Bulk liquids are removed from the air by the pre-

filter. The air then flows through the inlet shuttle valve, which diverts it to tower 1. The desiccant in tower 1 dries the

compressed air to -40°F PDP as it flows through. The dried air leaves tower 1 via the after-filter. A small part (15%) of

the compressed air is passed through the purge orifice by means of opening a two-way purge valve and thereby expanded

till its pressure is near-atmospheric. This expansion of the already-dry gas (purge air) to near-atmospheric pressure increases

its capacity to strip adsorbed water vapour from the desiccant bed in tower 2. The purge-air stream passes through tower

2, removing water vapour from the desiccant. This purge operation is carried out for 1 minute and 30 seconds. Then the

purge valve is closed, and the pressure in tower 2 begins to rise again. The repressurisation is carried out for 30 seconds.

The purge valve is opened, and purge air passes through tower 1.

During the first 2 minutes of each 4-minute cycle of operation, the following processes take place:

l The online tower (tower 1) dries compressed air for 2 minutes.

l The offline tower (tower 2) regenerates (adsorbed moisture is removed from the desiccant in it) for 1 minute and 30

seconds.

l The offline tower is re-pressurised for 30 seconds.

During the next half of the cycle, these processes are repeated with tower 2 being the online tower and tower 1 the offline

tower.

INSTRUCTION MANUAL - Dryspell Plus

Reference : Manual Version

6

Loading...

Loading...