41

XD1+_User manual_P5650.1600_Rev A

15.3 Cleaning labels

It is recommended to periodically clean the instrument with a damp cloth, to ensure the

instrument user interface and keypad is clean and legible.

15.4 Particulate entry/exit apertures

The particulate exit aperture is protected by a stainless-steel grille to minimise the ingress

of flora and fauna into the D1

+

device. It is recommended that the grille is checked and

cleaned during maintenance periods to ensure that it has not become clogged with ingress

that may obscure the particulate sensing airflow.

15.5 Compliance audit check

The D1

+

has been designed with an inbuilt compliance check routine / test to allow for the

infrequent checking of device functionality against a selection of sized reference particulates.

The compliance check uses certified sample material that can be passed through the sensor

to ensure that all sensing and sizing parameters are functioning as intended. Reference

material with a specific size spread allows each sensing region to be populated with reference

data during the process.

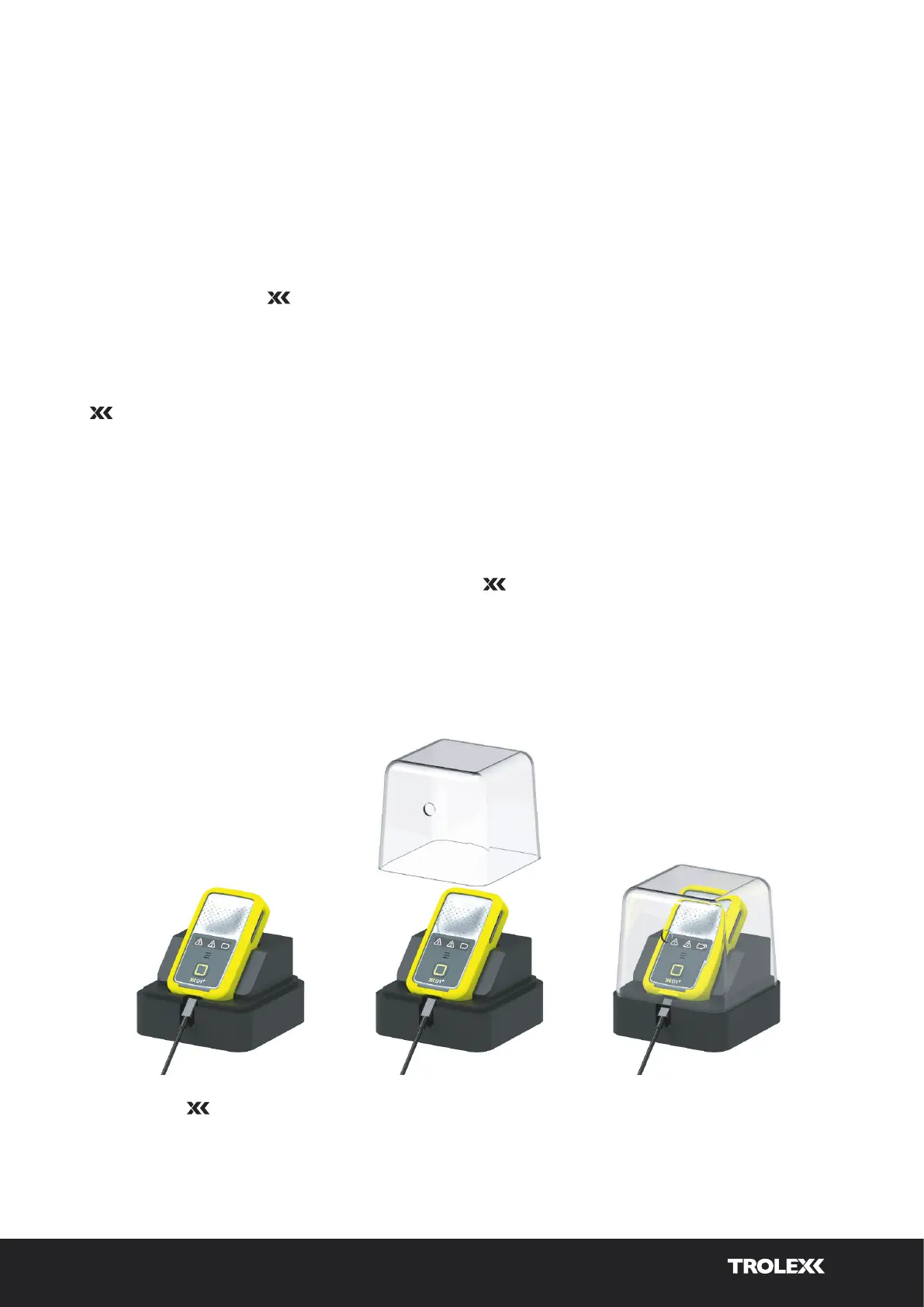

To run the compliance check sequence, connect the D1

+

to the BreatheLITE software

application, position in the supplied compliance base and cover with the particulate dispersion

hood before selecting the automated test routine within the device maintenance menu.

The use of the compliance base and particulate dispersion hood allows for units to be isolated

within a known volume during testing as highlighted below.

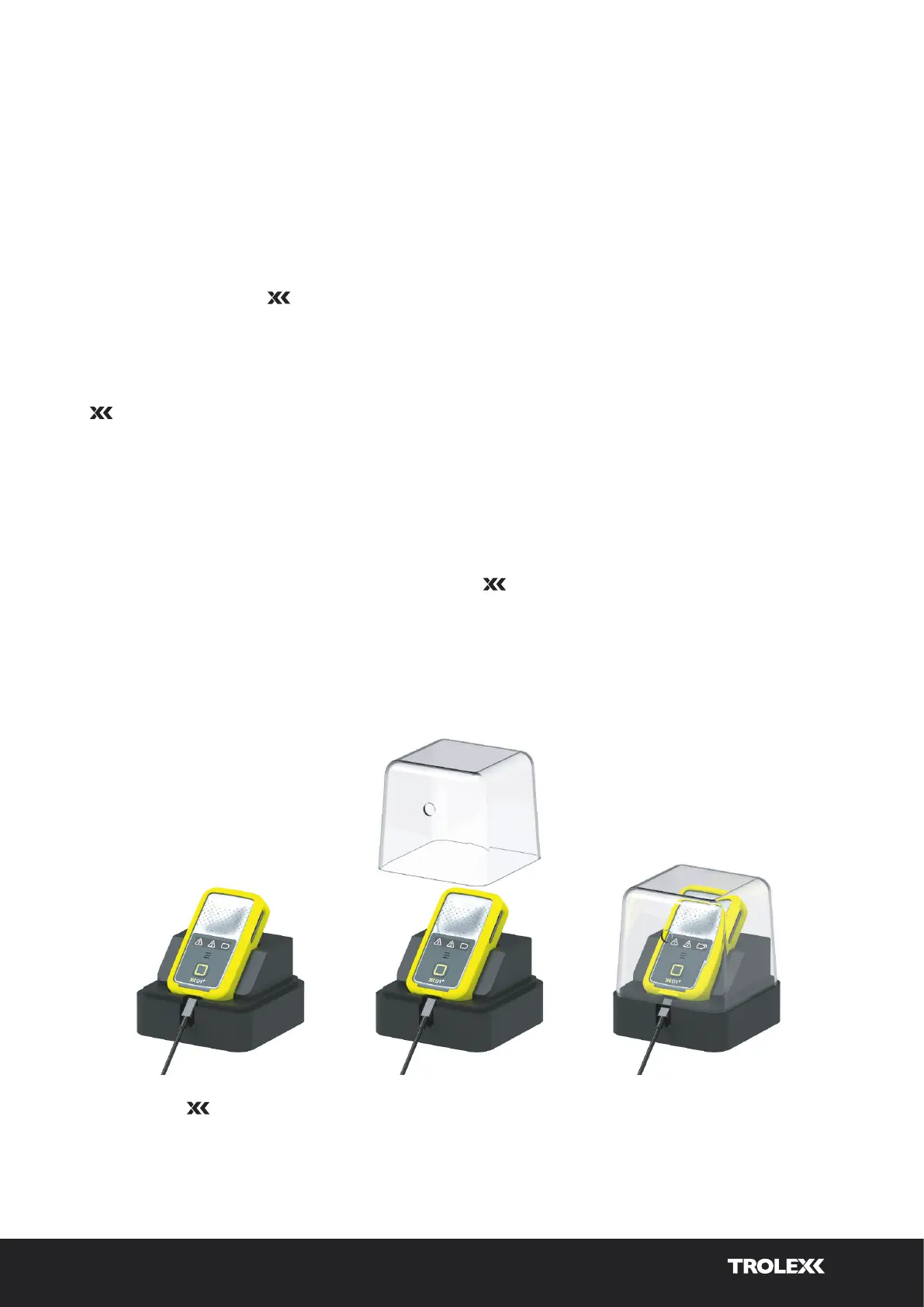

1. Insert the D1

+

into

the compliance dock.

2. Cover with particulate

dispersion hood.

3. Run BreatheLITE

compliance check.

Loading...

Loading...