Technical Data

Notice

– Connection has to be carried out by our Technical Support.

– Observe instructions for operation and maintenance according to the operating manual of

the exhaust system.

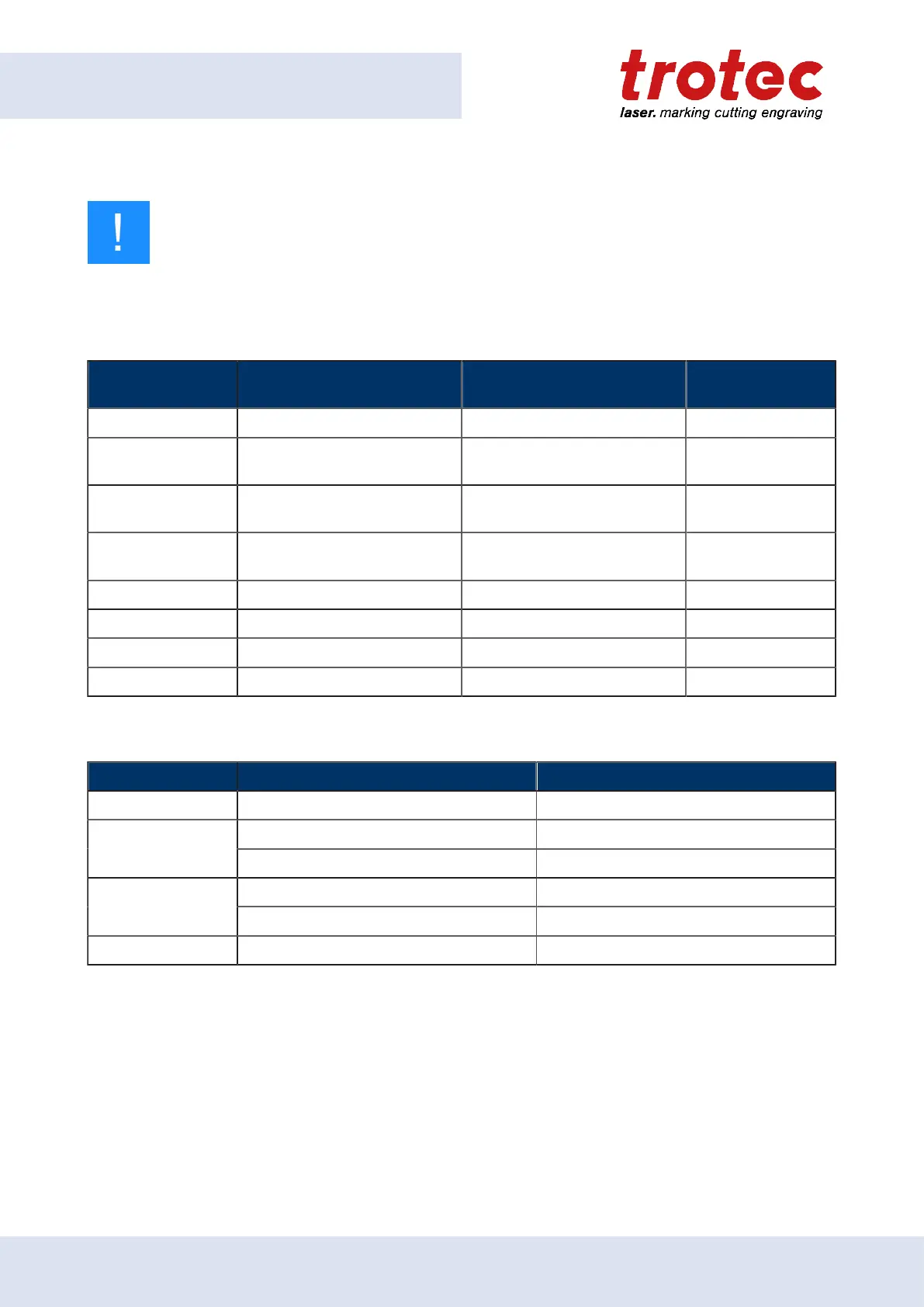

Technical data of the corresponding exhaust systems:

Exhaust system Hose connection ø [mm]

(inside diameter)

Volume flow [m³/h] Pressure[Pa]

Atmos Nano 45 200 8500 (230V)

Atmos Cube

(Atmos Compact)

80 250 8500 (230V)

5800 (115V)

Atmos Mono 70 320 8500 (230V)

5800 (115V)

Atmos Mono Plus 70 320 8500 (230V)

5800 (115V)

Atmos Duo Plus 70 (2x) 320 8500 (230V)

Vent Set 300 80 max. 1000 max. 2550

Vent Set 400 100 max. 1000 max. 3800

Vent Set 500 100 max. 1200 max. 7000

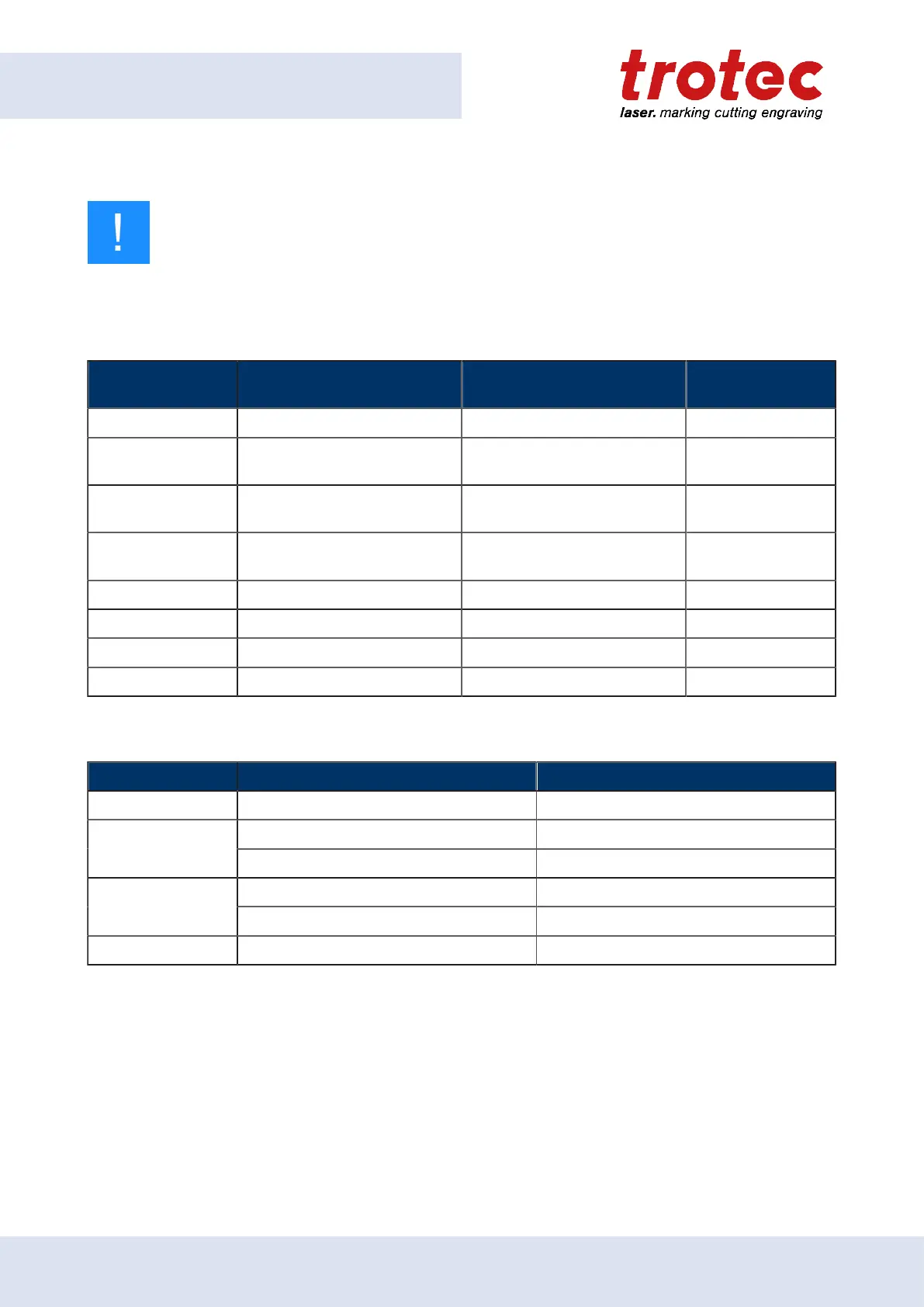

Requirements for the exhaust system:

Machine Volume flow [m³/h] Pressure [Pa]

Speedy 100 200 1000

200 (without table exhaust) 1000 (without table exhaust)Speedy 300

350 (with table exhaust) 1600 (with table exhaust)

300 (without table exhaust) 2500 (without table exhaust)Speedy 360

400 (with table exhaust) 4200 (with table exhaust)

Speedy 400 400 4200

The monitoring point for flow rate and pressure is at the exhaust port at the laser machine. Pressure loss

by hoses / pipes or filter parts of the exhaust system has to be determined and additionally calculated when

selecting a proper exhaust system.

A powerful exhaust system keeps the lifetime of optics and mechanical components, the cutting quality and

the laser power interacting with the workpiece from being impaired by fumes and dust accumulating in the

machine.

34

Loading...

Loading...