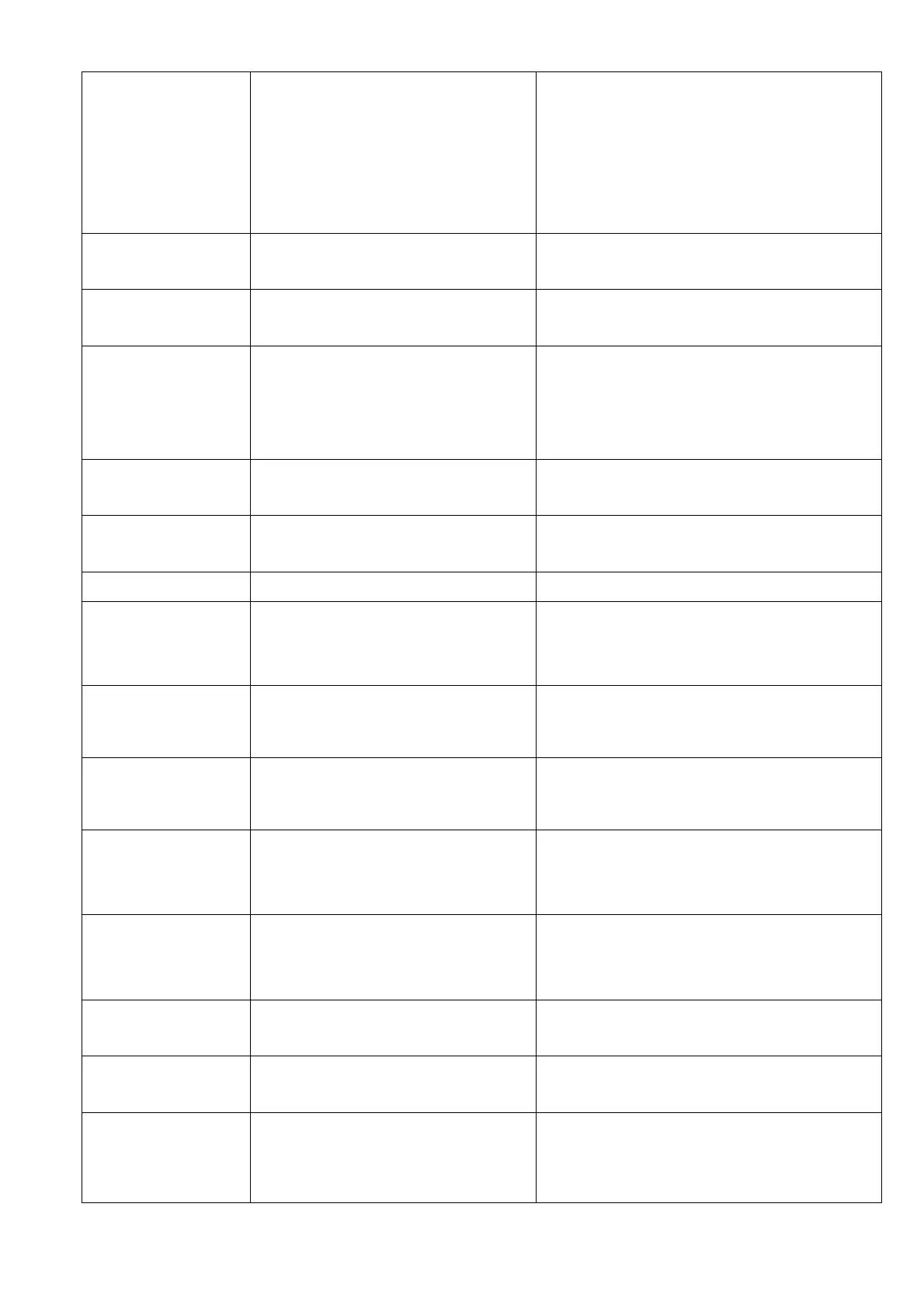

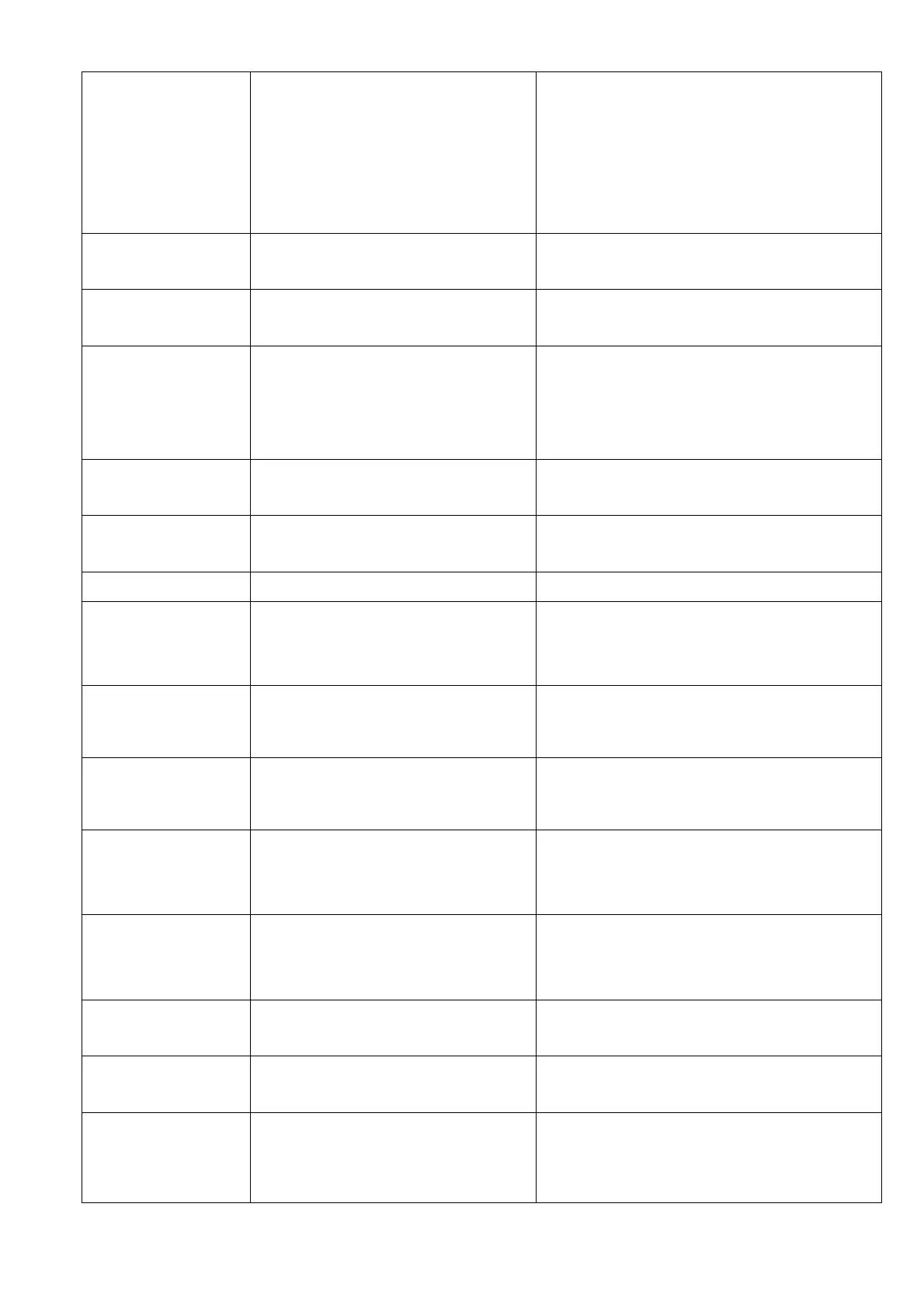

49

Poor Print Quality

* Ribbon and media is loaded incorrectly

* Dust or adhesive accumulation on the

printhead.

* Print density is not set properly.

* Printhead element is damaged.

* Ribbon and media are incompatible.

* The printhead pressure is not set

properly.

* Reload the supply.

* Clean the printhead.

* Clean the platen roller.

* Adjust the print density and print speed.

* Run printer self-test and check the printhead

test pattern if there is dot missing in the pattern.

* Change proper ribbon or proper label media.

* The release lever does not latch the printhead

properly.

LCD panel is dark and

keys are not working

* The cable between main PCB and LCD

panel is loose.

* Check if the cable between main PCB and LCD

is secured or not.

LCD panel is dark but

the LEDs are light

* The printer initialization is

unsuccessful.

* Turn OFF and ON the printer again.

* Initialize the printer.

LCD panel is dark and

LEDs are lit on, but

the label is feeding

forward

* The LCD panel harness connector is

loose.

* The LCD panel harness connector is plugged

upside down.

Ribbon encoder

sensor doesn’t work

* The ribbon encoder sensor connector

is loose.

* Fasten the connector.

Ribbon end sensor

doesn’t work

* The connector is loose.

* The ribbon sensor hole is covered with

dust.

* Check the connector.

* Clear the dust in the sensor hole by the blower.

Cutter is not working

* The connector is loose. * Plug in the connect cable correctly.

Label feeding is not

stable (skew) when

printing

* The media guide does not touch the

edge of the media.

* If the label is moving to the right side, please

move the label guide to left.

* If the label is moving to the left side, please

move the label guide to right.

Skip labels when

printing

* Label size is not specified properly.

* Sensor sensitivity is not set properly.

* The media sensor is covered with dust.

* Check if label size is setup correctly.

* Calibrate the sensor by Auto Gap or Manual

Gap options.

* Clear the GAP/Black-mark sensor by blower.

The left side printout

position is incorrect

* Wrong label size setup.

* The parameter Shift X in LCD menu is

incorrect.

* Set the correct label size.

* Press [MENU] Æ [SELECT] x 3 Æ [DOWN] x 5

Æ [SELECT] to fine tune the parameter of Shift

X.

Missing printing on

the left or right side of

label

* Wrong label size setup. * Set the correct label size.

RTC time is incorrect

when reboot the

printer

* The battery has run down. * Check if there is a battery on the main board.

Multi interface board

doesn’t work

* The installation is incorrect.

* Check if the board is plugged in the right

connector.

Power and Error LEDs

are blinking fast

* Power switch OFF and ON too fast.

* Turn off the printer and wait all LEDs are dark,

and turn on the printer again.

Wrinkle Problem

* Printhead pressure is incorrect.

* Ribbon installation is incorrect.

* Media installation is incorrect.

* Print density is incorrect.

* Media feeding is incorrect.

* Make sure the label guide touch the edge of the

media guide.

* Make sure label, paper core and ribbon are set

at the center of the spindle.

Loading...

Loading...