110

CAUTION

!

• Parts may remain very hot immediately after the engine has

stopped. Wear protective gloves and perform the operation

carefully so as not to touch possible hot parts around the

water drain cock.

• Fuel may spout out along with water being drained. If fuel

splashes over parts, wipe it off completely.

• If operation is continued for a long time while the sediment

chamber (fuel lter) level warning light is illuminated, the fuel

injection pump might seize up.

1. Open the top panel

(refer to page 83).

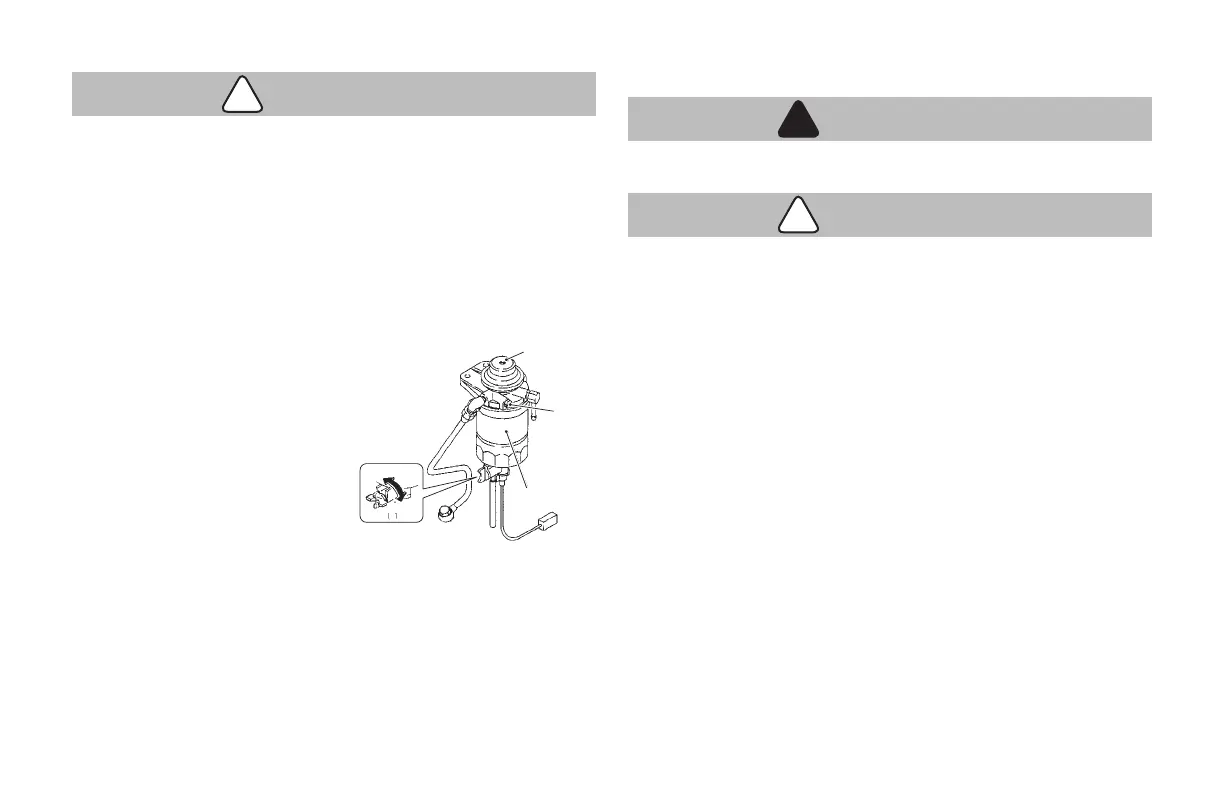

2. Place a container under the

fuel lter.

3. Put a container under the

water drain cock and loosen

the water drain cock 4 to 5

turns to drain the water.

4. After the water has been

completely drained, tighten

the drain cock.

5. Perform air purge operation (at right).

AIR PURGE

(DIESEL LIFT TRUCKS)

WARNING

!

• Never allow open ames, smoking or other sources of

ignition in the operation area.

CAUTION

!

• Do not remove the screw completely, otherwise a large

amount of fuel may spout out.

• Fuel may spout out from the air purge screw hole during

air purge. Be sure to block the hole with a cotton cloth or a

similar item to prevent fuel from splashing over surrounding

parts.

• If fuel spills during replenishment, be sure to wipe it off.

NOTE:

Air purge operation for diesel engine lift trucks is not normally

necessary. If it becomes necessary follow the procedure below.

When relling an empty fuel tank and/or draining water from the water

separator, purge the air out of the fuel system.

1. Loosen the air purge screw at the upper part of the fuel lter.

2. Move the priming pump up and down until no further air-bleed

comes out of the air purge screw.

3. Tighten the air purge screw.

Priming pump

Air

bleeding

screw

Close

Open

Water drain cock

Fuel filter

Loading...

Loading...