Section

3-13AB46 Work Platform

Maintenance

3.11

3.11 FRONT WHEEL BEARINGS

Removal

1. Disconnect battery negative terminal.

2. Loosen wheel lug nuts.

3. Raise front axle using 2-ton jack. Support front axle

using two 2-ton jack stands.

4. Remove wheel lug nuts and remove wheel.

5. Remove axle dust cap.

6. Remove cotter pin, hub nut, and washer.

7. Remove hub assembly.

8. Clean all parts using a suitable solvent.

9. Inspect bearings, cones and cups for wear and

replace if necessary.

NOTE: Cups do not need to be replaced if they are

not damaged.

Installation

NOTE: Torque all hardware to torques listed on page

3-312unless otherwise specified.

1. Apply a liberal coating of grease to each cup.

2. Pack the inside bearing with a liberal amount of

multi purpose grease and position it in the hub.

Install new grease seal.

3. Apply a thin coating of grease to the spindle and

slide the hub onto the spindle.

4. Pack the outside bearing cone with multi purpose

grease and slide it onto the spindle until it seats in

the outer bearing cup.

5. Install the washer and hub nut. While rotating the

hub, tighten the hub nut until the hub drags. Then

back the nut off until a slot lines up with the hole in

the spindle.

6. Install a new cotter pin and bend the end up over

the nut.

7. Install the dust cap and wheel. Torque the lug nuts

to 90 ft. lbs. (123 N-m).

8. Remove jack stands and lower the axle to the

ground.

9. Connect battery negative terminals and/or Anderson

connectors.

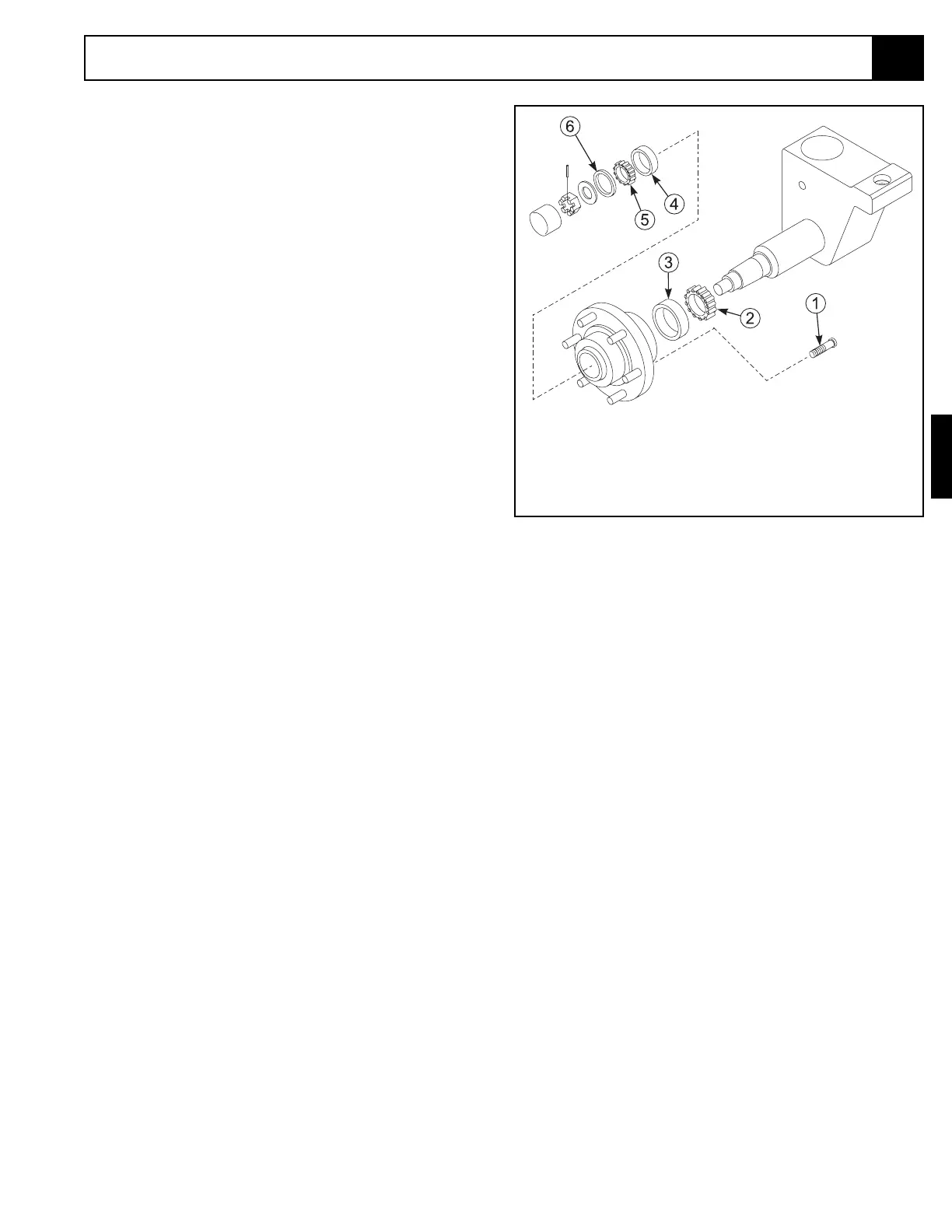

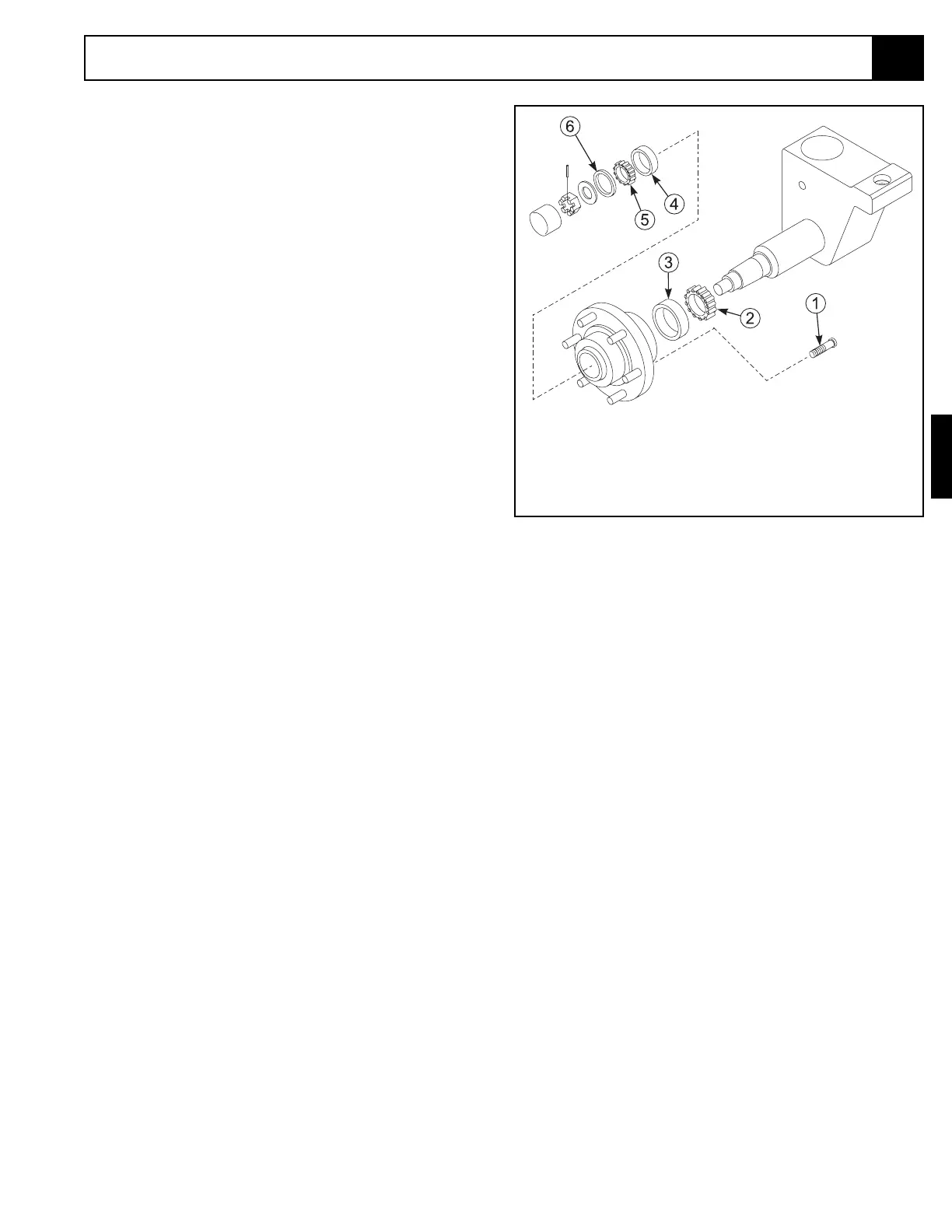

Figure 3-14: Front Axle Assembly

1. Stud

2. Rear Bearing Cone

3. Rear Cup

4. Front Bearing Cone

5. Front Cup

6. Grease Seal

Repair kit (068577-010) includes:

Loading...

Loading...