Section

3-25AB46 Work Platform

Maintenance

3.16 Slave Cylinder

REMOVAL

1. Extend boom until slave cylinder trunion pins are

accessible. Support the cage assembly.

2. Remove rod end pin retaining bolt.

3. Mark and disconnect hoses and immediately cap

the openings to prevent contamination.

4. Using a metal drift, remove rod end pin.

5. Remove trunion pin retaining bolts and using a pin

puller, remove trunion pins.

6. Carefully remove slave cylinder.

DISASSEMBLY

Note: Provide a clean work area for this operation

and observe clean assembly practices. Seals and

hydraulic cylinder components are highly sensitive to

contamination that may not be visible to the naked

eye.

1. Remove set screw from cylinder tube and unscrew

head from cylinder.

2. Carefully pull rod assembly from cylinder.

3. Clamp rod end in vise and turn off rod extension.

Slide piston off of rod.

NOTE: Rod extension is loctited (Loctite #262) onto

rod.

4. Slide the head off of the rod.

5. Remove 1/4 inch socket head cap screws from rod

end of cylinder and remove internal seal block from

cylinder.

6. Remove seal kit components (wipers, rod seals, o-

rings and backup rings) from head, piston and seal

block.

7. Thoroughly clean all parts with solvent. Rinse the

inside of the tube and allow to drain. A high pres-

sure rinse and wipe with a lint free rag is preferable.

8. Inspect parts for scratches, pits, or polishing. Check

seal groves and sealing surfaces. Scratches or pits

deep enough to catch the fingernail are unaccept-

able; replace the cylinder. Polishing is a sign of

uneven loading. When this occurs, the surface

should be checked for roundness. Cylinders not

round within .007" should be replaced.

ASSEMBLY

NOTE: Torque all hardware to torques listed on page

3-32 unless otherwise specified.

1. Lubricate all components and seals with clean

hydraulic oil prior to assembly.

Note: To avoid cutting the seals, do not use sharp

edged tools during seal replacement. After installing

seals allow at least one hour for the seals to elasti-

cally restore to their original shape before assembling

cylinder.

2. Install new seal kit items to piston, head and internal

block.

3. Lubricate rod wiper and seal with hydraulic oil and

slide head onto rod.

4. Clean threaded end of rod and rod extension using

loctite primer.

5. Using loctite #262, install rod extension onto rod.

6. lubricate seal block static seal and carefully push

seal block into cylinder. Secure seal block using 1/4

socket head cap screws.

7. Lubricate seals on piston, head and seal block with

hydraulic oil.

8. Carefully slide rod assembly into cylinder.

9. Thread head into cylinder. Be sure hole for set

screw aligns with hole in cylinder tube.

10. Clean set screw in loctite primer. Install set screw

using loctite #242.

INSTALLATION

1. Follow steps from "REMOVAL" section in reverse

order to install cylinder.

2. Remove boom support.

3. Slowly raise and lower boom several times. Check

hydraulic connections for leaks. Check for proper

slave cylinder operation.

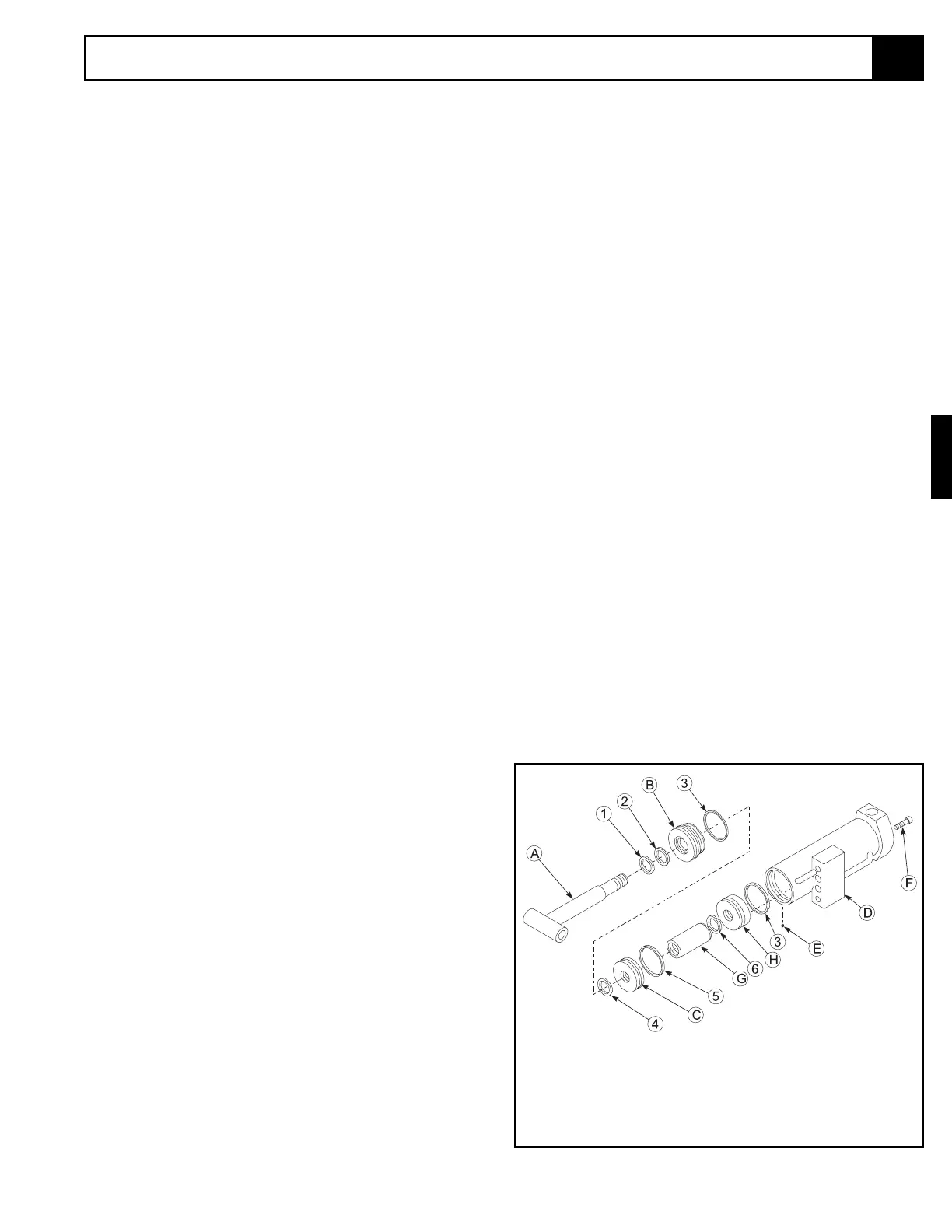

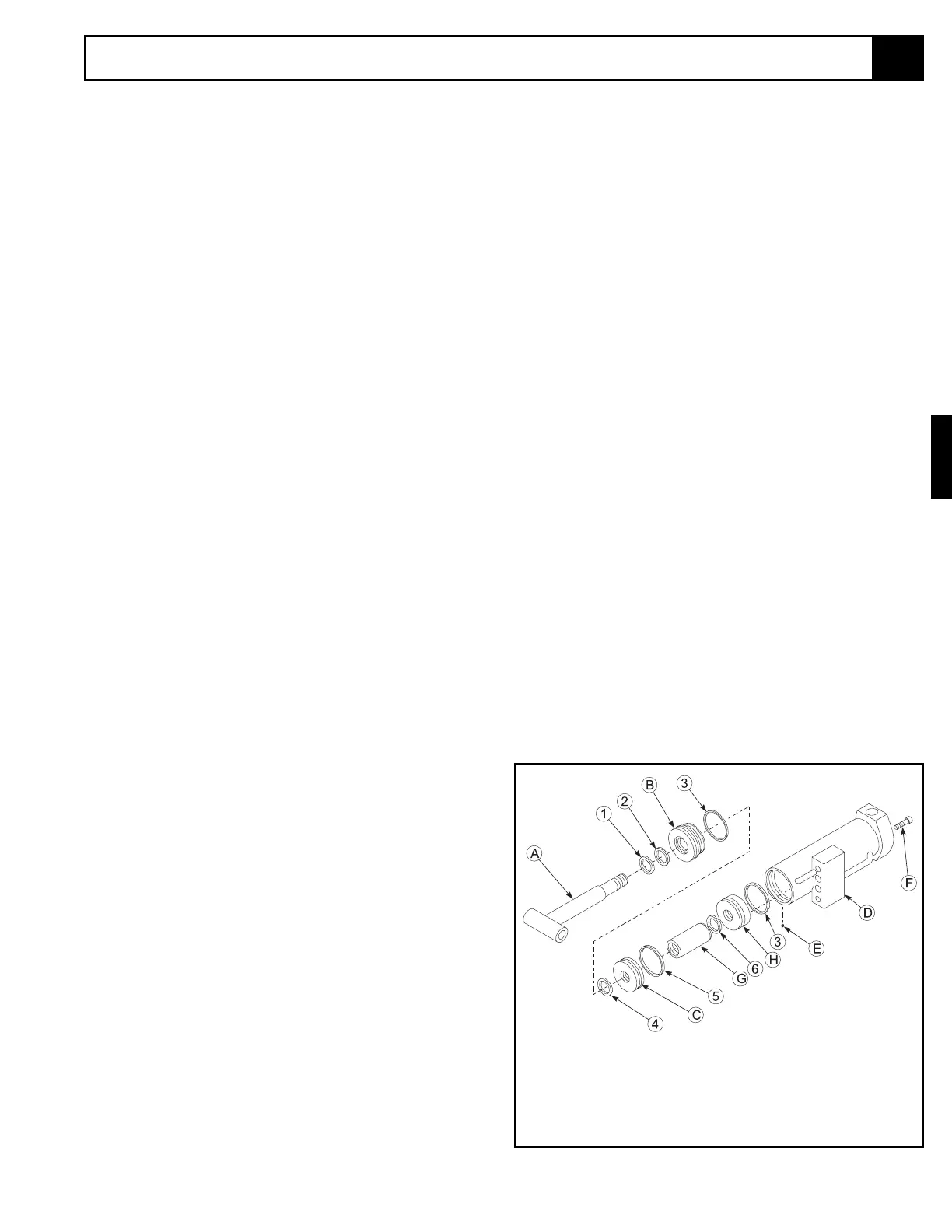

Figure 3-25: Slave Cylinder

E. Set Screw

F. Cap Screw

G. Rod Extension

1. Rod Wiper

2. Rod Seal

3. Static Seal

4. Static Seal

5. Piston Seal

6. Rod Seal

A. Rod

B. Head

C. Piston

D. Cylinder

3.16

Seal kit (068455-010)

includes:

Loading...

Loading...