47Installation and maintenance instructions ecoTEC plus 0020031552_03

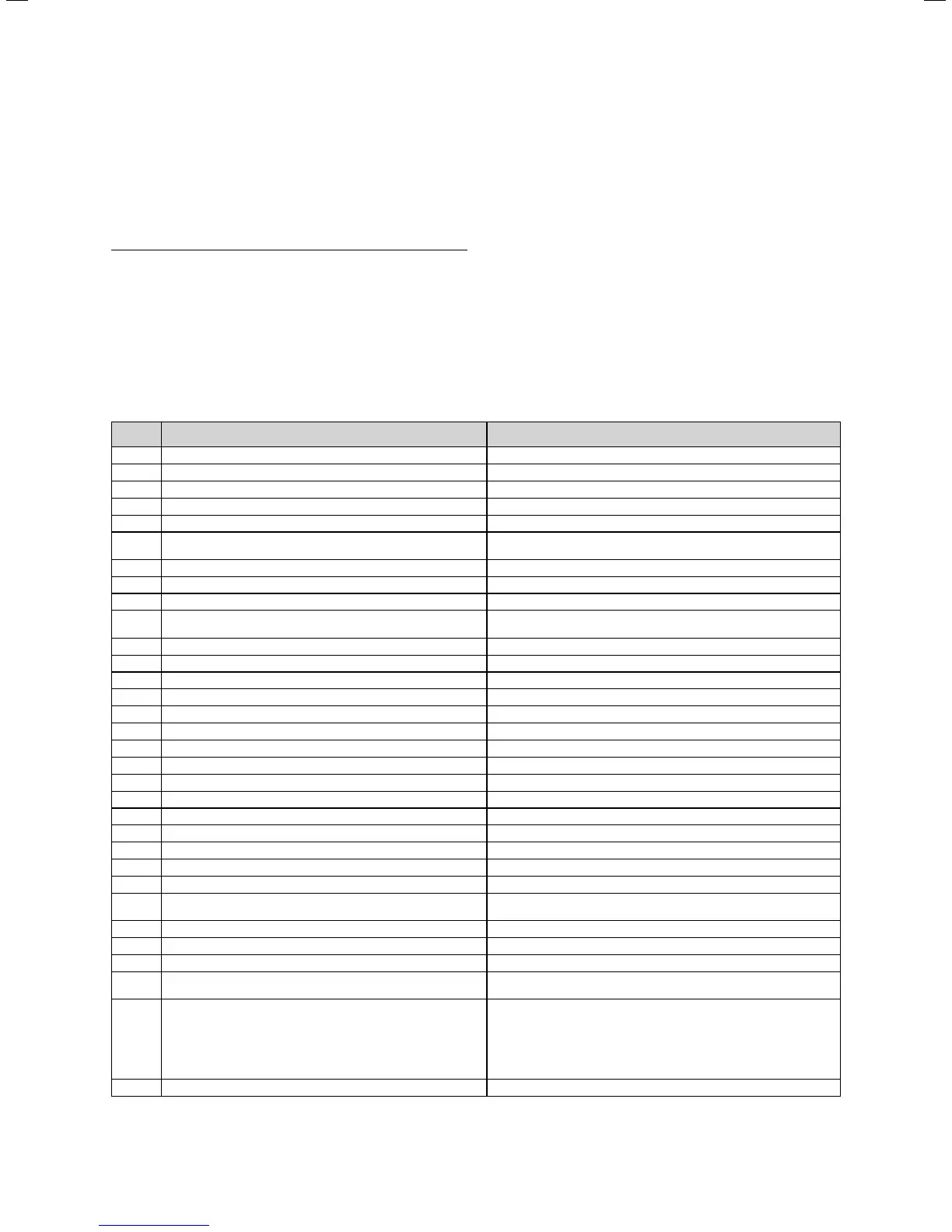

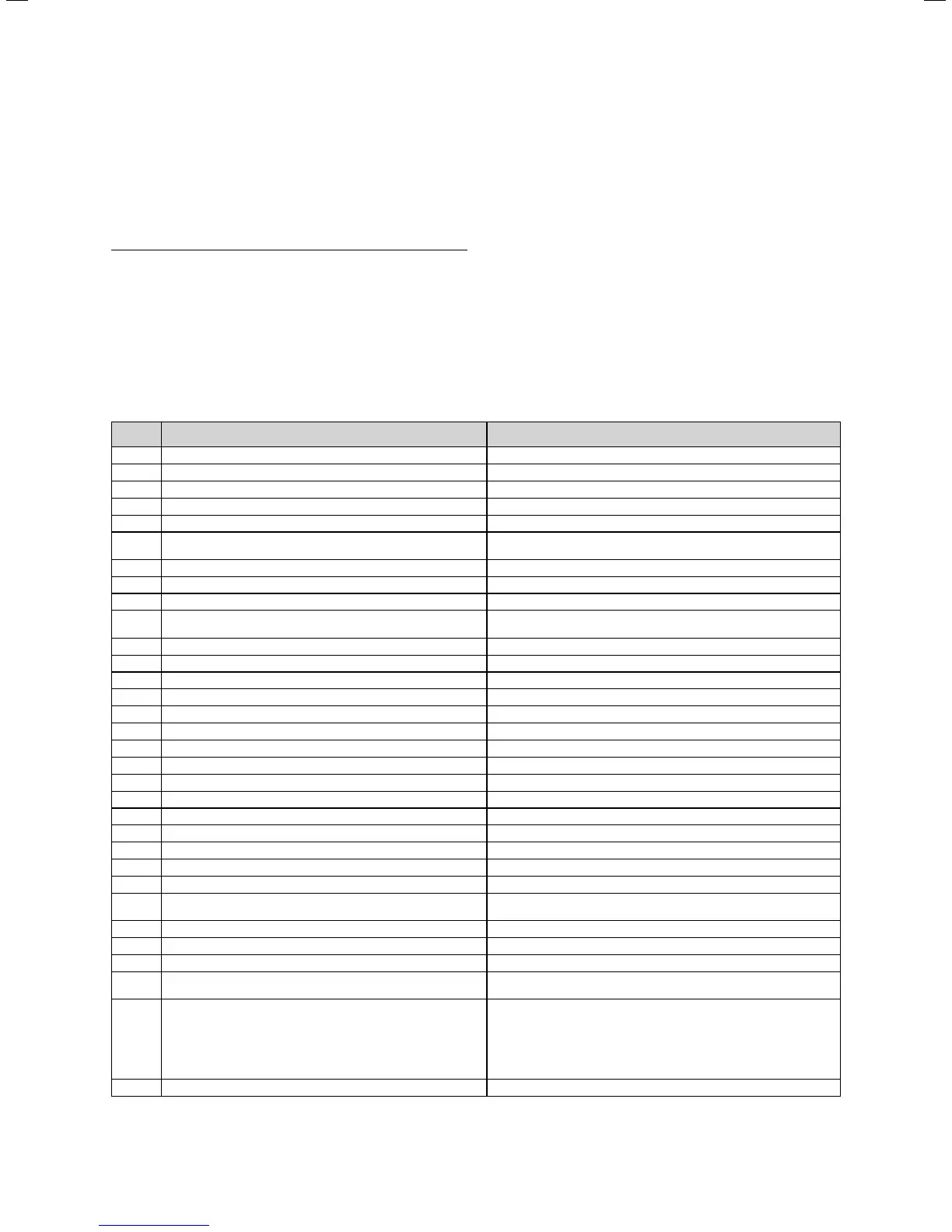

8.1.2 Diagnostic codes

In the diagnostic mode, you can change certain parame-

ters or display more information.

The diagnostic information is divided into two diagnostic

levels. Access to the second diagnostic level can only be

permitted after entering a password.

a

Caution!

Danger of incorrect operation and wrong unit

parametrisation!

Access to the second diagnostic level must be

used exclusively by a heating engineer.

First diagnostic level

• Press the "i“ and "+“ buttons simultaneously.

The display shows "d.00“.

• Use the buttons "+“ or "–“ to move to the desired di-

agnostic number of the first diagnostic level (see the

Table 8.2).

• Press the "i" button.

The associated diagnostic information is shown in the

display.

• If necessary you can change the value with the but-

tons "+“ or "–“ (display flashing).

• Save the new value by holding down the "i“ button for

approx. 5 seconds until the display no longer flashes.

You can end the diagnostic mode as follows:

• Press the "i“ and "+“ buttons simultaneously. or

• Do not press any button for about 4 minutes.

The current heating flow temperature appears in the

display again.

Troubleshooting 8

Display

Meaning Displayed value/settable value

d.0 Heating partial load Adjustable heating partial load in kW (factory setting: max. output)

d.1 Water pump over run time for heating mode 2 - 60 minutes (factory setting: 5 minutes)

d.2 Max. anti cycle time heating at 20°C flow temperature 2 - 60 minutes (factory setting: 20 minutes)

d.3 Measured value of the domestic hot water temperature in °C

d.4 Measured value for the warmstart sensor in °C

d.5 Flow temperature target value or return temperature tar-

get value, if return flow regulation selected

in °C, max. of the value set in d.71

limited by an eBUS controller, if fitted)

d.6 Hot water target temperature in °C, 35 to 65 °C

d.7 Warm start target temperature in °C, 40 to 65 °C

d.8 Heat demand of external controllers (terminal 3-4) 1=closed (heating requirement); 0=opened (no heating requirement)

d.9 Flow target temperature from external analogue regulator

to terminal 7-8-9/eBus

in °C, minimum from ext. eBus target value and target value

terminal 7

d.10 Status internal heating pump 1, 2 = on, 0 = off

d.11 Status external heating pump (via accessory module) 1 to 100 = on, 0 = off

d.12 Cylinder charging pump (via accessories module) 1 to 100 = on, 0 = off

d.13 External hot water circulation pump (via accessory module) 1 to 100 = on, 0 = off

d.22 Hot water demand 1 = on, 0 = off

d.23 Summer /winter function 1 = Winter, 0 = Summer

d.25 Hot water activation via eBUS controller 1 = yes, 0 = no

d.30 Control signal for both gas valves 1 = on, 0 = off

d.33 Fan speed target value in upm/10

d.34 Fan speed actual value in upm/10

d.35 Internal diverter valve position 0 = heating; 100 = hot water; 40 = mid-position

d.36 Hot water flow sensor in l/min

d.40 Flow temperature actual value in °C

d.41 Return flow temperature actual value in °C

d.44 digitalised ionisation voltage Display range 0 to 102, >80 no flame, <40 good flame display

d.47 External temperature (only on weather-compensated

Vaillant controllers)

actual value in °C

d.67 Remaining burner anti-cycling time in minutes

d.76 Unit variants (device specific number) 00 to 99

d.90 Status of the digital controller 1 = identified, 0 = unidentified (eBUS Address <=10)

d.91 DCF status with connected external probe with DCF77 re-

ceiver (not available in the UK)

0 = no reception, 1 = reception, 2 = synchronised, 3 = valid

d.92 Module recognition shift load storage tank Setting range:

0 = not recognised

1 = no communication via PE-BUS; Module recognised earlier

2 = Communication OK

Setting = 0: Unregister shift load storage tank from combi boiler

(if shift load storage tank is to be de-installed, set d.92 = 0)

d.97 Activation of the second diagnostic level Password: 17

Table 8.2 Diagnostic codes of the first diagnosis level

Loading...

Loading...