Run 9

________________________________________________________________________________________

_______________________________________

9-73

9.4.3.1 Aggregate pushed back by bump bar.

If the angle is sufficient (about 45 degrees) then the panel will aggregate (920) will push

back naturally and it is recommended to set the “enable concave sensor” setting (970) to

NO. Refer 9.3.6 Advanced Controls: Panel Shapes

This disables the bump switch (914) and prevents inadvertent operation during a cycle.

Thus, when the aggregate approaches the concave condition, the bump bar (915) makes

contact with the panel. This sends a signal to the PLC to change automatically a number

of machine states.

The speed changes to bump bar speed (see 9.3.5 Advanced Controls: Feed),

The bias force changes to bump bar bias

These changes are held on by Hold Count Bump bar, so when the bump bar stops

touching the panel, there will be a distance travelled as defined by this count, until the

speed and bias return to normal.

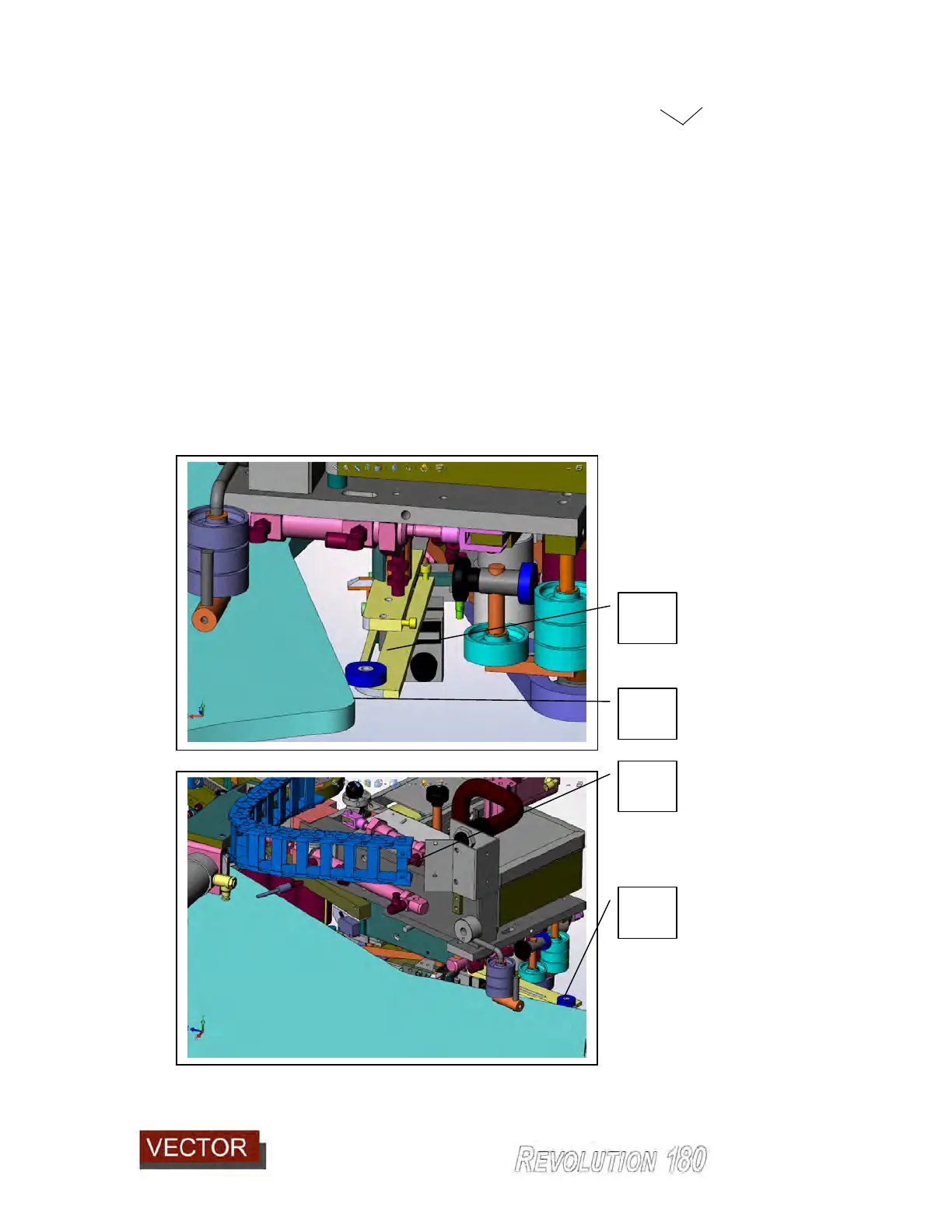

Fig 3

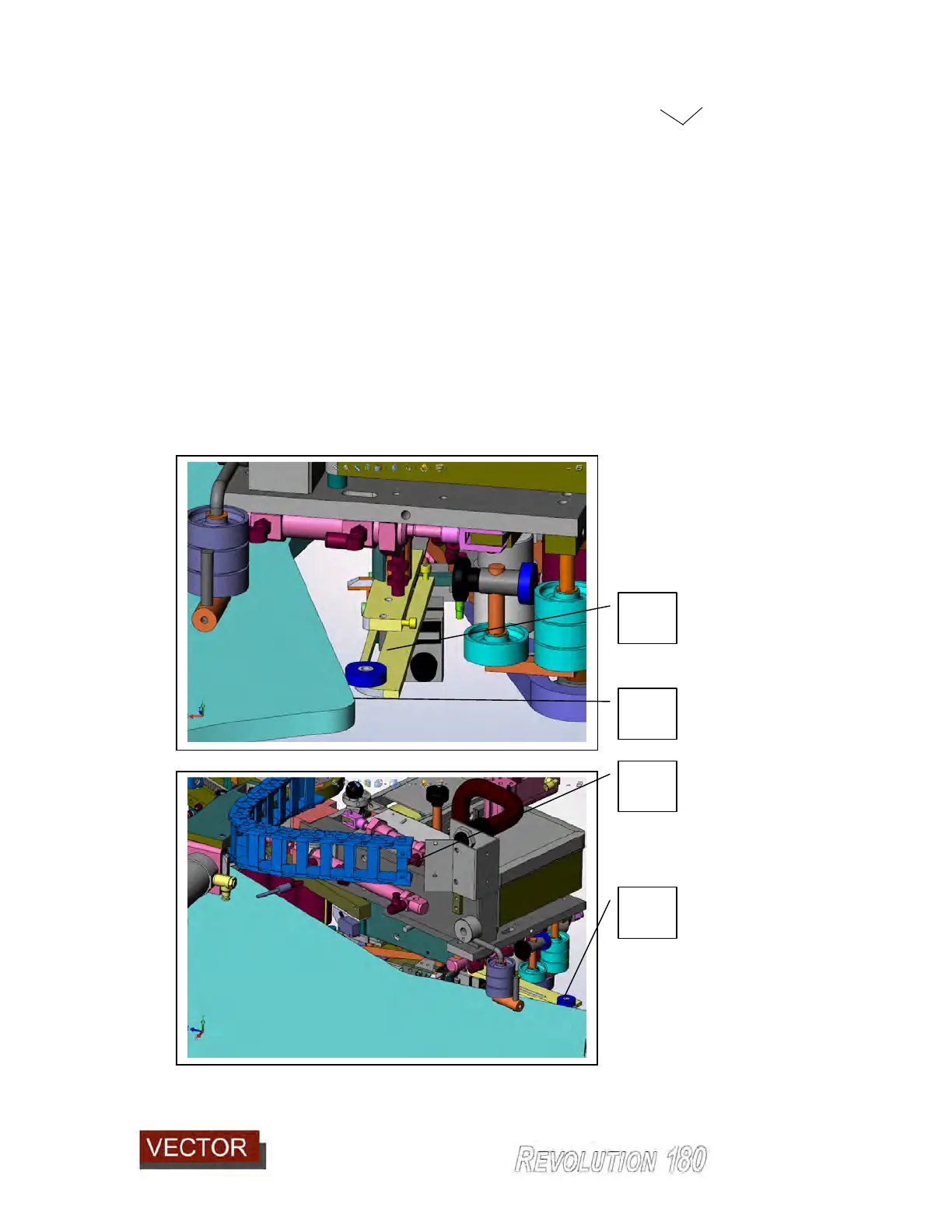

Fig 4

Aggregate (920) being

pushed back by bump

bar (915)

925

919

Aggregate showing

bump bar making initial

contact with panel

920

925

Loading...

Loading...