Troubleshooting and remedies 11

________________________________________________________________________________________

_______________________________________

11-3

Tape not feeding

(continued)

set correctly (continued next page)

Password protected

refer technical support

11 Glue remaining on after

tape has passed

Screen setting is set too

long

Glue and debris is

obstructing the tape

present switch holding it

on

Reset

Clean switch

8 Glue not flowing

Cartridge sticking to inside

of teflon tube.

Use purge function until

glue flows freely

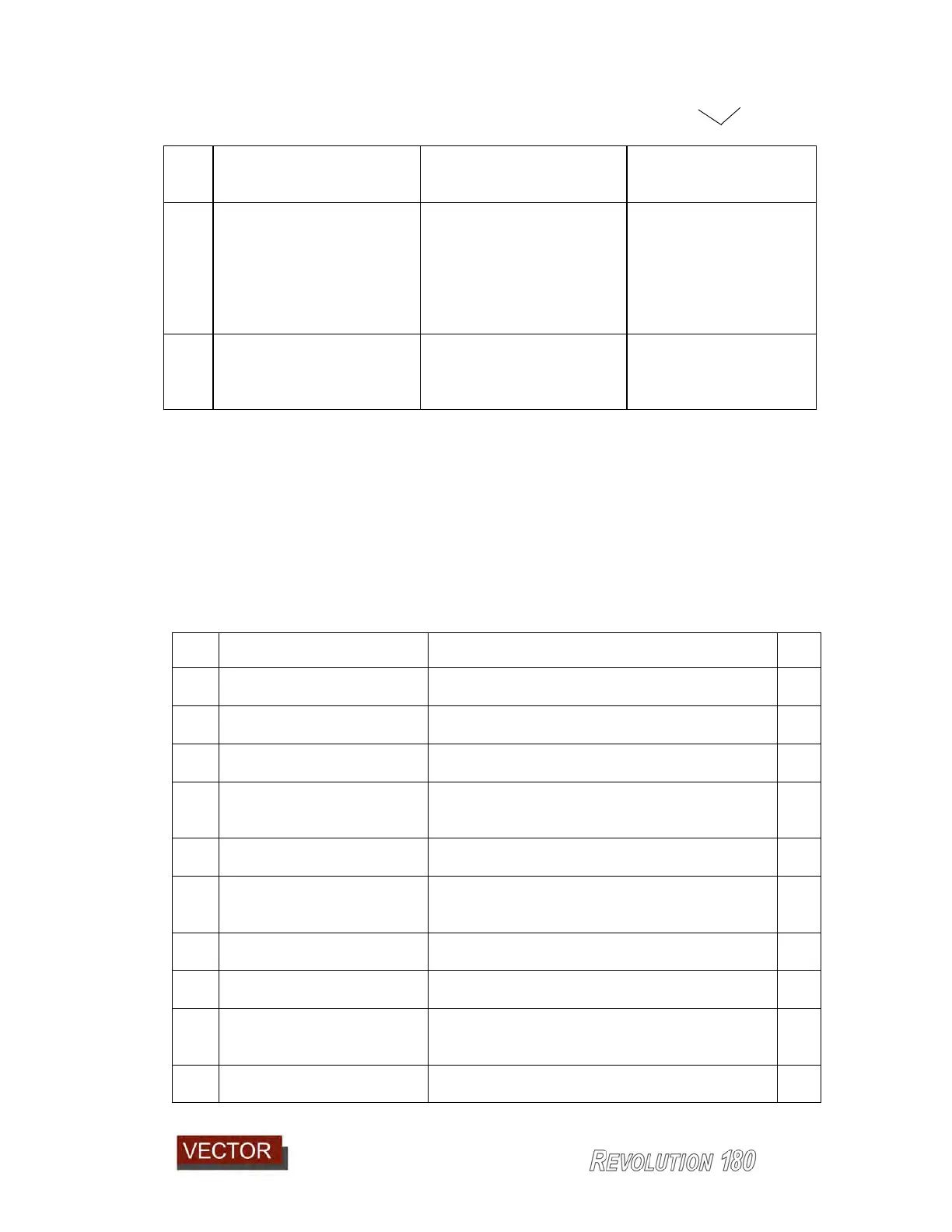

11.2 LIST OF ALARMS

These are alarms which appear on the control screen, their causes and remedies

When fault has been remedied, the screen error is cleared by pressing the RESET

function key on the screen.

These messages appear at the bottom of the Control Screen and are blinking red.

1 Emergency stop

See SIMPLE FAULT SCHEDULE 1 + 2

2 X Axis overspeed

Axis movement exceeds limit speed. Check

for drive faults and reset

3 Y Axis overspeed

Axis movement exceeds limit speed. Check

for drive faults and reset

4 Set Point outside range

Positioning set point outside acceptable

range. Choose new position

5 Glue temperature low

This fault appears until min operating

temperature is reached then automatically

clears.

6 Load new glue cartridge

Glue piston has reached proximity switch

indicating need to load a new glue cartridge

7 Clear tape

The Tape Present switch (S30 %I5.15) is still

activated indicating either tape still in guide or

faulty operation of the switch

8 Z Axis not down

Z Axis has not lowered within the allowable

time. Check for obstruction or fault

9 Z Axis not up

Z Axis has not raised within the allowable

time. Check for obstruction or fault

10 Board sensor trip

The board sensor (S28 %I1.9) has sensed no

board present during a cycle causing the

machine to stop.

11 Board sensor at Z up

Board sensor still detecting when Z axis is

instructed to lift after a cycle indicating not

Loading...

Loading...