Pumpdown Alarms—If a compressor is unable to pump down the circuit within one minute, the liquid line

solenoid valve will be toggled ON, then OFF. This is done because the liquid line solenoid valve could be

stuck and this could fix it. If, after another minute, the compressor is unable to pump down the circuit, the

liquid line solenoid valve will be toggled again. This will continue until either the compressor is able to

pump down the circuit or the liquid line solenoid valve is toggled three times. If, after three times of

toggling the liquid line solenoid valve and waiting 1 minute, the compressor is still unable to pump down

the circuit, the compressor will be turned Off, a pump down failure alarm will be activated for that circuit

and the Pump Down Alarm Code for that tandem compressor bank will be set to 1.

There is a re-pump down if the Low Pressure Switch closes again after the compressor has been pumped

down; six re-pump down cycles per hour are allowed. At the seventh request of a re-pump-down, the

compressor will not be started to re-pump down the circuit again, a pump down failure alarm is activated

for that circuit and the Pump Down Alarm Code for that tandem compressor bank is set to 2.

Tandem Bank 1 PD Alarm Code—Compressor Circuit 1 is pump down alarm code; possible values are 0, 1

and 2.

Tandem Bank 2 PD Alarm Code—Compressor Circuit 2 is pump down alarm code; possible values are 0, 1

and 2.

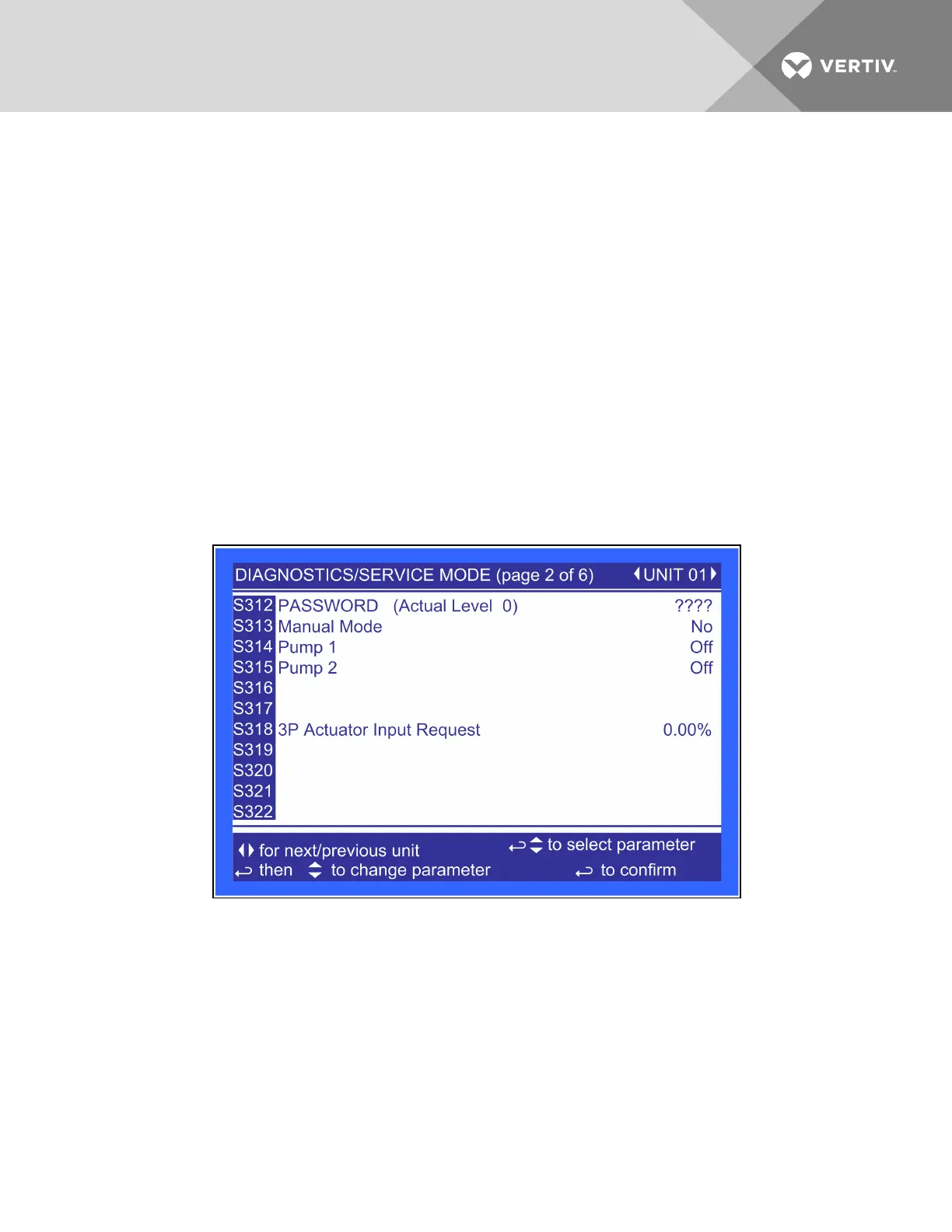

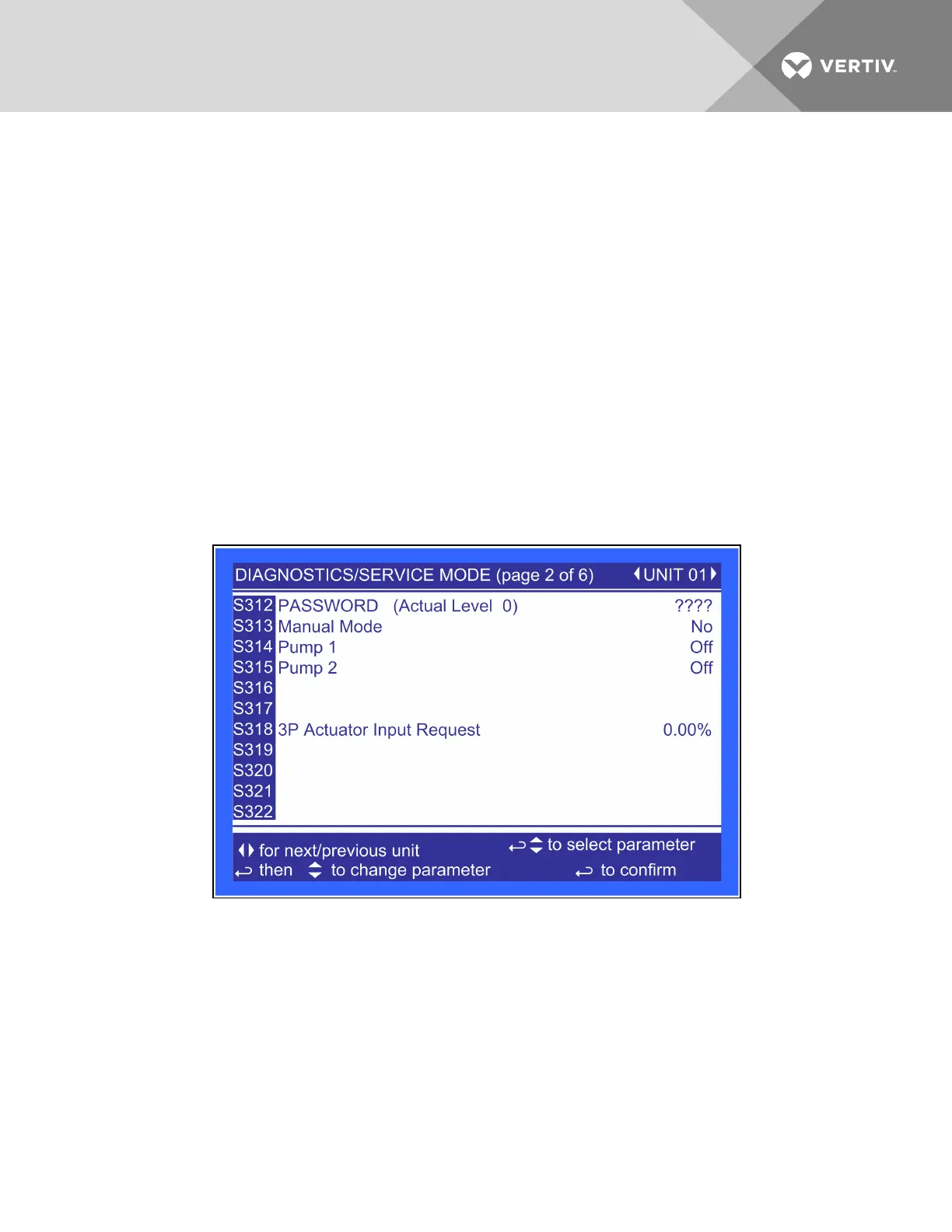

Figure 6.27 Diagnostics/Service mode, page 2 of 6

Manual Mode—Used to place the Liebert iCOM control in manual mode. This is the initial setting

necessary to activate any of the following items. When the Liebert iCOM is not in manual mode, each

service menu item shows the current status of each parameter.

Pump 1—Used to start the unit’s Pump 1.

Pump 2—Used to start the unit’s Pump 2.

3P Actuator Input Request—A service tool to view the % call for cooling.

Vertiv | Liebert® XDC™ User Manual | 90

Loading...

Loading...