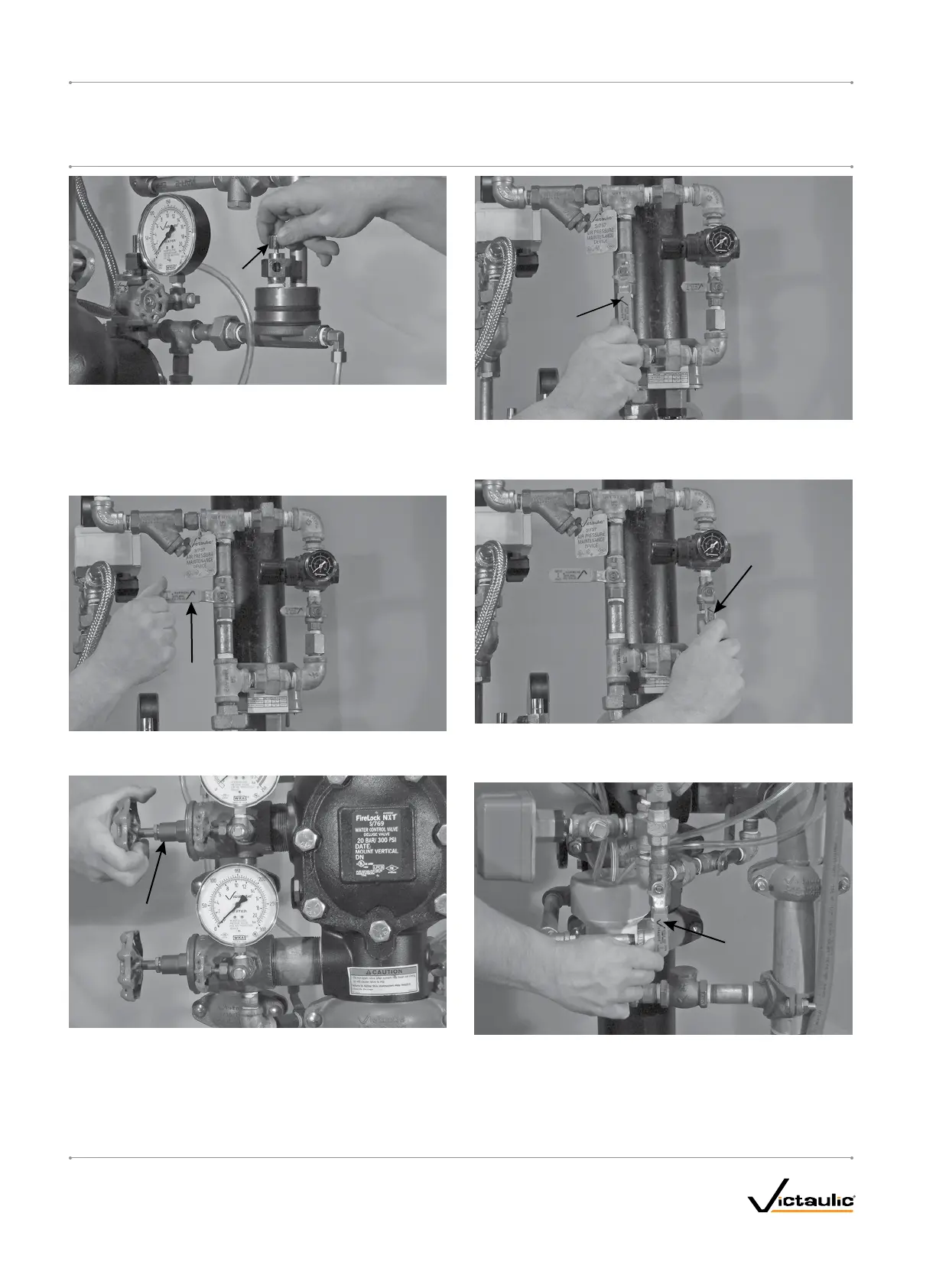

Auto Vent

Sleeve

12. When the system reaches approximately 10 psi/0.7 Bar, and no

additional moisture is being released from the Auto Vent, pull up

on the Auto Vent Sleeve of the Series 776 Low-Pressure Actuator.

NOTE: The Auto Vent Screw should seal and remain in the set

(“UP”) position.

13. Confirm that the solenoid is closed.

Fast-Fill

Ball Valve

14. When system air pressure is established, close the fast-fill ball

valve on the AMTA.

System Main

Drain Valve

15. Open the system main drain valve slightly to lower the system air

pressure approximately 3 to 5 psi/0.2 - 0.3 Bar. DO NOT drop the

system air pressure below 10 psi/0.7 Bar.

15a. Make sure the AutoConvert Assembly Air Pressure Gauge (Item 28

on page 5) maintains the normal system air pressure and does not

track the system air loss created in step 15.

Fast-Fill

Ball Valve

16. Re-charge the system with air by turning on the compressor or by

opening the fast-fill ball valve on the AMTA (fast-fill ball valve is

shown above). Charge the system to 13 psi/0.9 Bar minimum.

Slow-Fill

Ball Valve

17. Open the slow-fill ball valve on the AMTA. NOTE: Failure to leave

the slow-fill ball valve open may allow system pressure to drop,

resulting in valve operation in the event of a system leak.

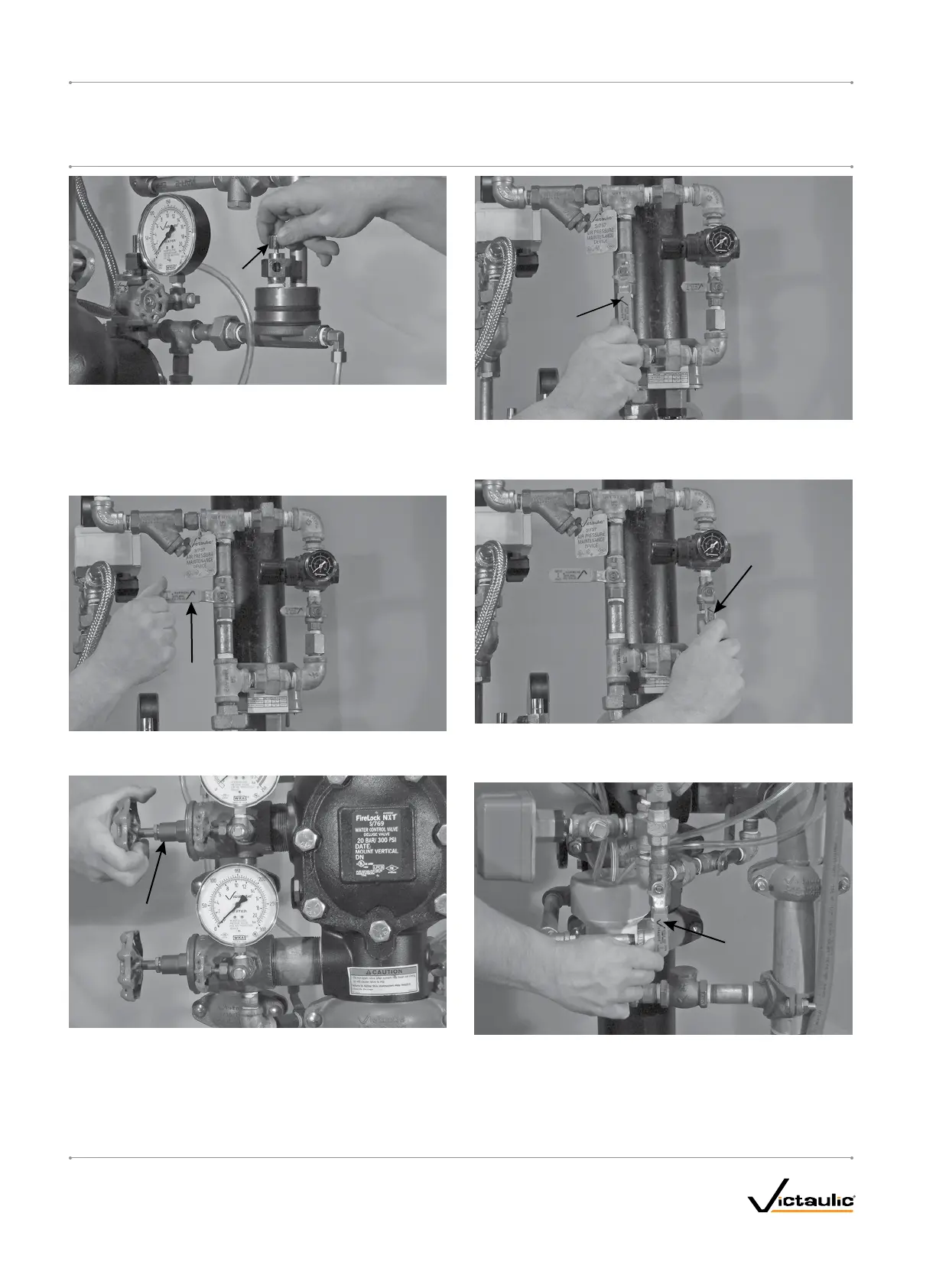

Diaphragm-Charge-

Line Ball Valve

18. Open the diaphragm-charge-line ball valve. Allow water to flow

through the Auto Drain tube.

I-769P.AC/ELEC_22

FireLockNXT™AutoConvertPreactionValve

SERIES 769

PreactionElectricAutoConvertDryTrim

I-769P.AC/ELEC

INSTALLATION,MAINTENANCE,ANDTESTINGMANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2009 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_B

Loading...

Loading...