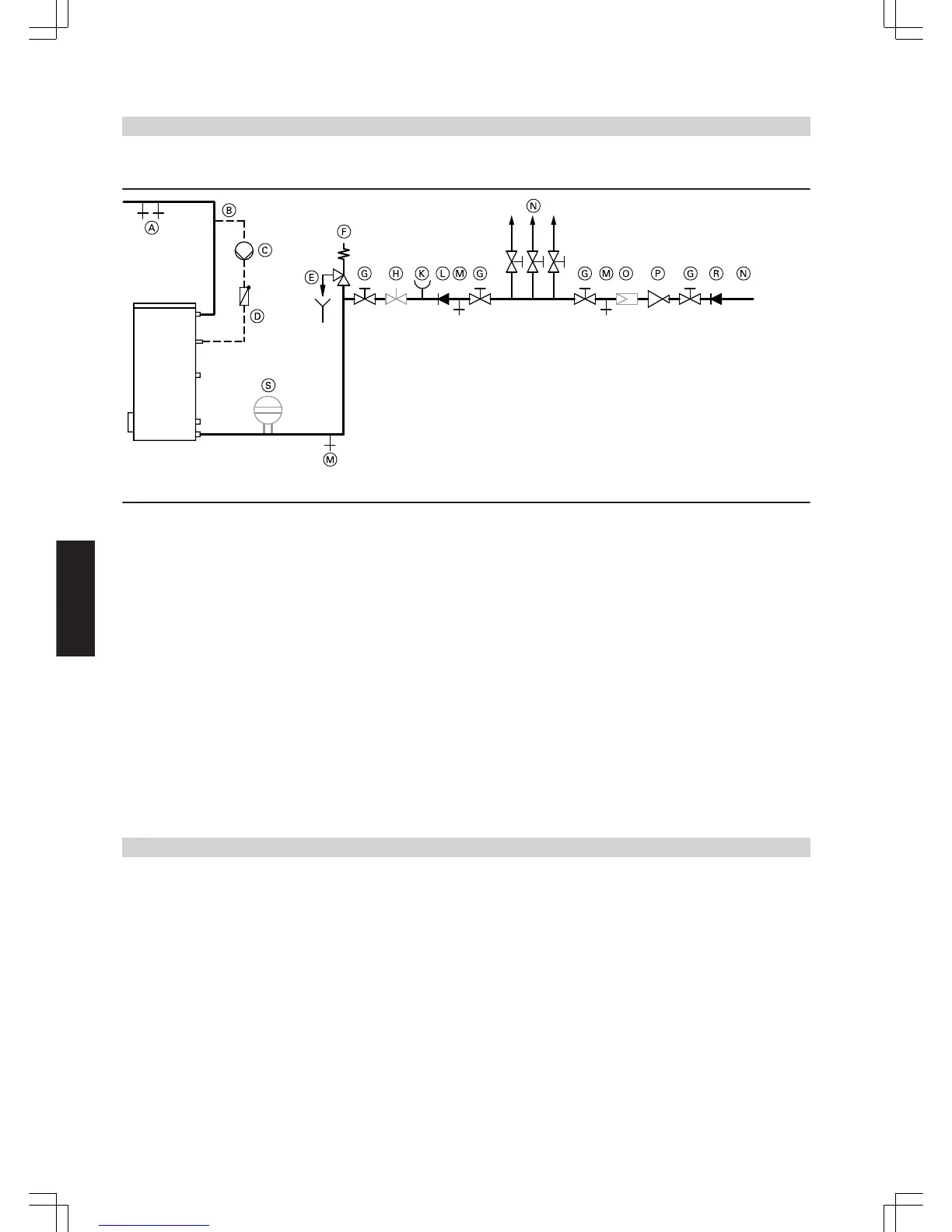

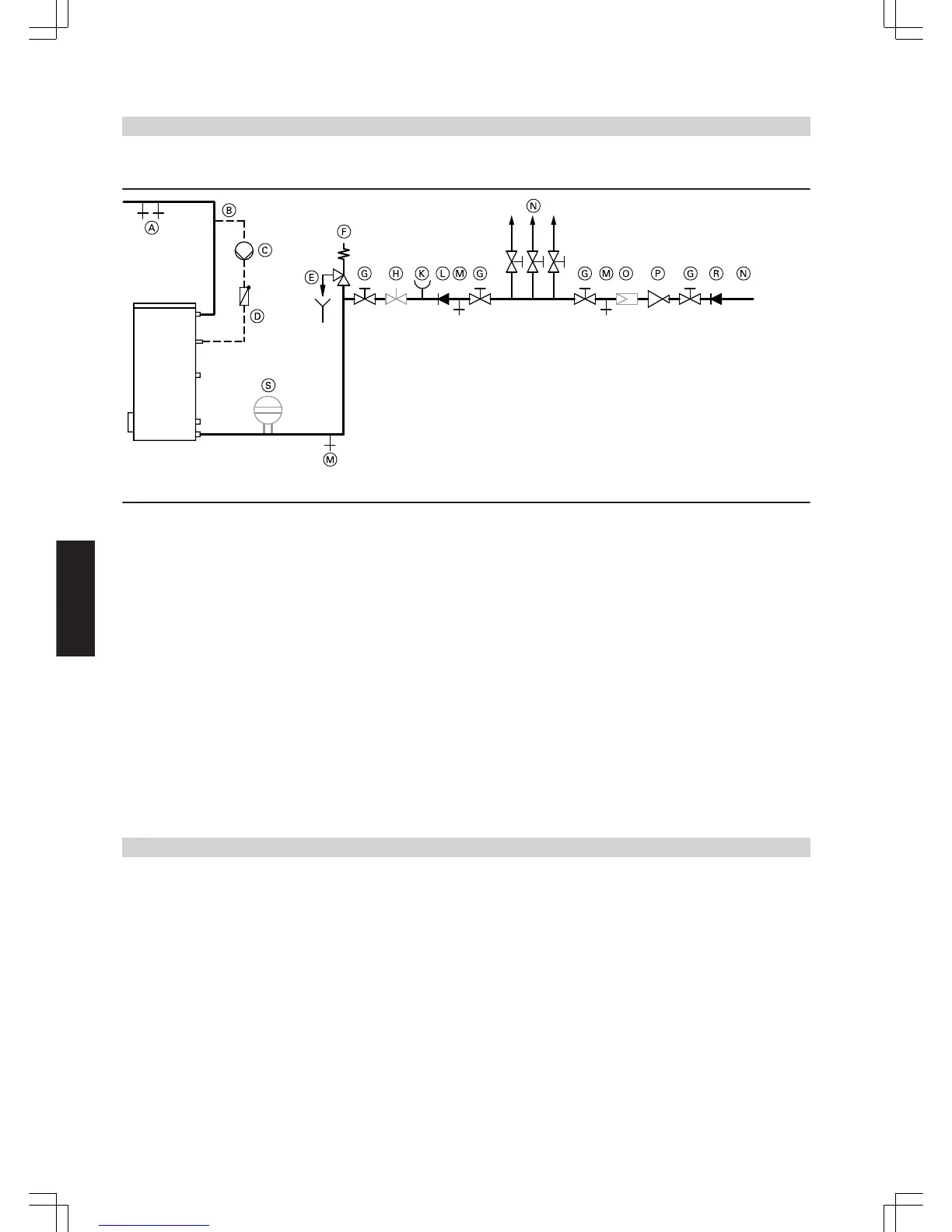

3.5 DHW cylinder connection on the DHW side

Connection to DIN 1988, example: Vitocell 100-V

A

DHW

B

DHW circulation line

C

DHW circulation pump

D

Spring-loaded check valve

E

Blow-off line with a visible outlet

F

Safety valve

G

Shut-off valve

H

Flow regulating valve

(Recommendation: we recommend installing this valve and

adjusting the max. water flow rate in accordance with the 10

minute peak output of the DHW cylinder.)

K

Pressure gauge connector

L

Non-return valve

M

Drain

N

Cold water

O

Drinking water filter

P

Pressure reducer to DIN 1988-2, issue Dec, 1988

R

Non-return valve/pipe separator

S

Diaphragm expansion vessel, suitable for drinking water

Information on drinking water filter

According to DIN 1988-2, a drinking water filter should be installed in

systems with metal pipework. Viessmann and DIN 1988 also recom-

mend the installation of a drinking water filter when using plastic pipes,

to prevent contamination entering the DHW system.

The safety valve must be installed. Recommendation: Install the safety valve higher than the top edge of

the cylinder. This protects the valve against contamination, scaling and

high temperatures. The DHW cylinder must not be drained when work-

ing on the safety valve.

Installation accessories

4.1 Accessories for connecting DHW cylinder to boiler

System connections with Vitocell

Complete with:

■ Connecting pipes

■ Circulation pump, fully wired

■ Check valve

For part numbers for the relevant cylinder types, see pricelist.

DHW cylinder

(cont.)

34

VIESMANN

VITOGAS

4

5822 428 GB

Loading...

Loading...