Do you have a question about the Volvo Penta D11 and is the answer not in the manual?

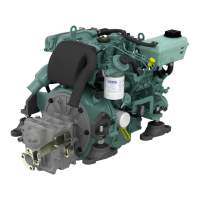

| Cylinder Configuration | Inline 6 |

|---|---|

| Compression Ratio | 17.5:1 |

| Engine Type | Diesel |

| Bore | 123 mm |

| Stroke | 152 mm |

| Cooling System | Liquid-cooled |

| Aspiration | Turbocharged and intercooled |

| Emissions Compliance | IMO Tier II, EPA Tier 3 |

| Engine Model | Volvo Penta D11 |

Hazards related to fuel, oil, chemicals, and batteries, and precautions.

Details of the limited warranty coverage and owner responsibilities.

Importance of regular service and using genuine Volvo Penta parts.

Specific requirements for emission-certified engines regarding maintenance and parts.

Description of the ignition lock positions and key usage.

Explanation of the tachometer and its displayed information.

Operation of the control panel for station handling and EVC system navigation.

How to display and navigate information within the EVC system.

Details on the engine display mode and its navigation.

Accessing and navigating the menu for system settings and calibration.

Operation of the single lever for gearshift and throttle.

Operation of the dual lever system for gearshift and throttle.

Procedures for activating the low-speed function.

Step-by-step guide to starting the engine.

Methods for starting the engine using the ignition switch or button.

How to interpret and respond to engine alarms and fault messages.

Safe techniques for maneuvering the boat, including gear shifts.

Managing multiple control stations on the boat.

Procedures for safely stopping the engine from an active station.

General procedures for managing engine and EVC system alarms.

How malfunctions are detected and how they affect engine performance.

Steps to acknowledge an alarm and silence the buzzer.

Guide to diagnosing symptoms and identifying possible causes of malfunctions.

Table correlating engine symptoms with potential causes and solutions.

How fault messages are structured and what information they provide.

Procedure for jump-starting the engine using auxiliary batteries.

Manual method to shift gears in case of electrical control failure.

Mandatory initial inspection by an authorized workshop.

Schedule for the first service inspection after initial engine use.

Maintenance tasks required after the first 1000 hours of operation.

General inspection procedures for the engine and engine bay.

Procedure for inspecting and replacing engine air filter cartridges.

How to check the condition and replace drive belts.

Information on oil change intervals and oil level checks.

Step-by-step guide for changing the engine oil and filters.

Procedure for replacing oil and by-pass filters during oil changes.

Detailed instructions for replacing the engine fuel filter.

Checks and draining procedures for the primary fuel filter.

Steps for replacing fuel filter cartridges, with engine running or stopped.

Information on the engine's internal cooling system and recommended coolant.

Instructions for mixing coolant concentrate with water.

Steps for draining the engine's coolant and associated systems.

How to flush the cooling system when changing coolant.

Overview of the external cooling system and its components.

Inspecting and replacing zinc anodes for corrosion protection.

How to check and replace the seawater pump impeller.

Procedure for checking and cleaning the optional seawater filter.

Specifications for the D11-670 engine model.

Oil capacity, pressure, and grade recommendations for lubrication.

Fuel specifications and requirements for engine operation.

System voltage, AC generator, and battery specifications.

Specifications for ZF reverse gear models, including oil and pressure.