62

TAMD72P (EDC)

The system also determines the maximum torque

available at the engine speed registered without risk-

ing damaging the engine. To protect the engine at

high engine coolant temperatures, high charge air

temperatures or excessive charge air pressure the

EDC temporarily reduces the amount of fuel (re-

duced engine output) until the current values normal-

ize.

The EDC control module also has a diagnostics sys-

tem (On-board diagnostics OBD) which assists us-

ers/service technicians to quickly determine the

cause of any malfunctions on the system using the

diagnostic lamp or a diagnostic scan tool (ST).

Electronic Diesel Control (EDC) system

(TAMD72P)

The injection pump on the TAMD72P

(“TAMD72EDC”) engine has an electronic governor.

The governor contains an electro-magnetic actuator

which effects the injection pump control rod and so

the amount of fuel injected (engine output).

The EDC system measures the charge air pressure

and charge temperature and calculates the available

air mass. This determines the amount of fuel injected

(smoke limiter function). To achieve minimal emis-

sions at start the system measures the engine cool-

ant temperature and adapts the amount of fuel re-

quired.

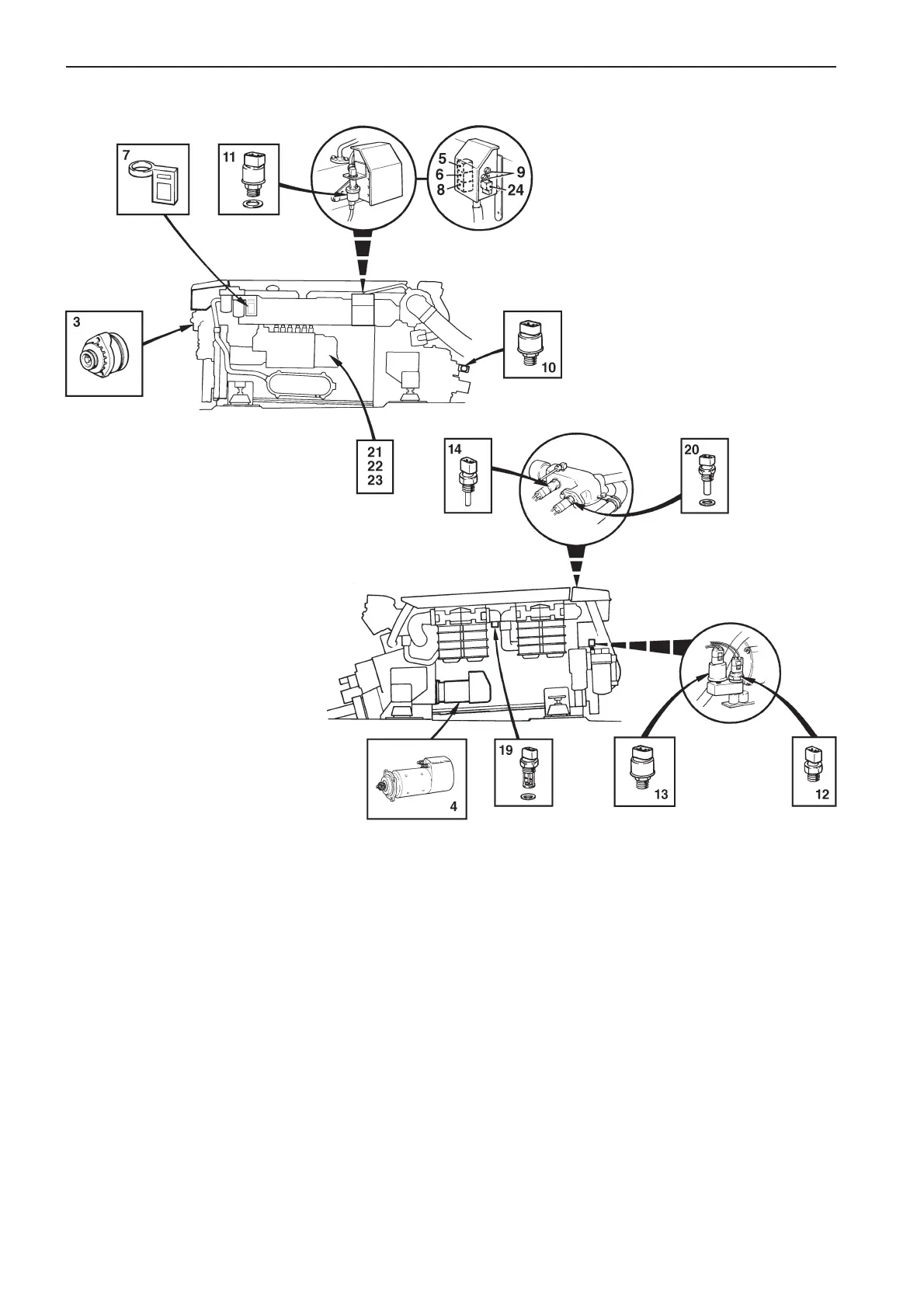

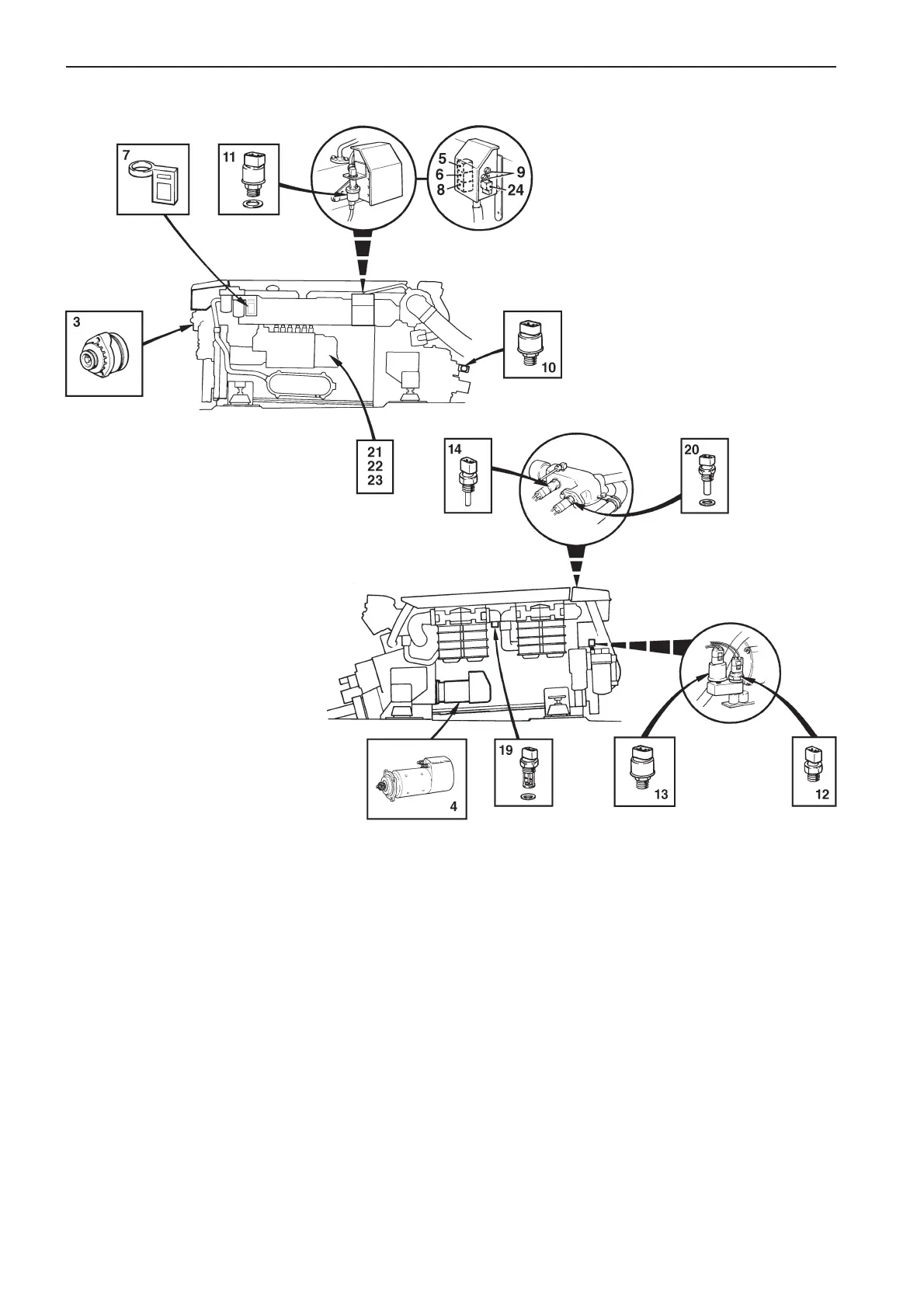

TAMD72P (EDC)

Note: The components in the figures are

numbered the same as in the engine’s wiring

diagrams on pages 79 and 81.

3. Generator (GEN)

4. Starter motor

5. Starter relay

6. Main relay

7. Electronic Diesel Control (EDC) control

module box (incl. fuel temperature sender,

EDC and turbo pressure sender, EDC)

8. Stop relay

9. Semi-automatic fuses

10. Oil pressure sender, reverse gear.

11. Pressure sender, turbo pressure, instru-

ment

12. Oil pressure switch, engine

13. Oil pressure sender, engine

14. Engine coolant temperature (ECT) sender,

instrument

19. Temperature sender, charge air, EDC

20. Engine coolant temperature (ECT) sender,

EDC

21. Position sender, control rod

22. Engine speed (RPM) sender

23. Electro-magnetic actuator, EDC

24. 2-pin connector, data link connector (DLC)

Loading...

Loading...