66

Maintenance – Electrical System

NOTE! Always stop the engine and break

the current using the main switches before

working on the electrical system.

Also read the section entitled “Electrical

system – Important” on pages 64–65.

Resetting/replacing fuses

Ensure that you use the correct size of fuse when

replacing safety fuses. Never fit a more powerful

fuse.

Make sure that you always have spare fuses on

board.

Note: If the same fuse often trips or needs to be re-

placed, consult authorized service personnel so that

they can investigate the cause of the overload.

Semi-automatic fuses

The semi-automatic fuses are reset by pressing the

respective fuse’s button.

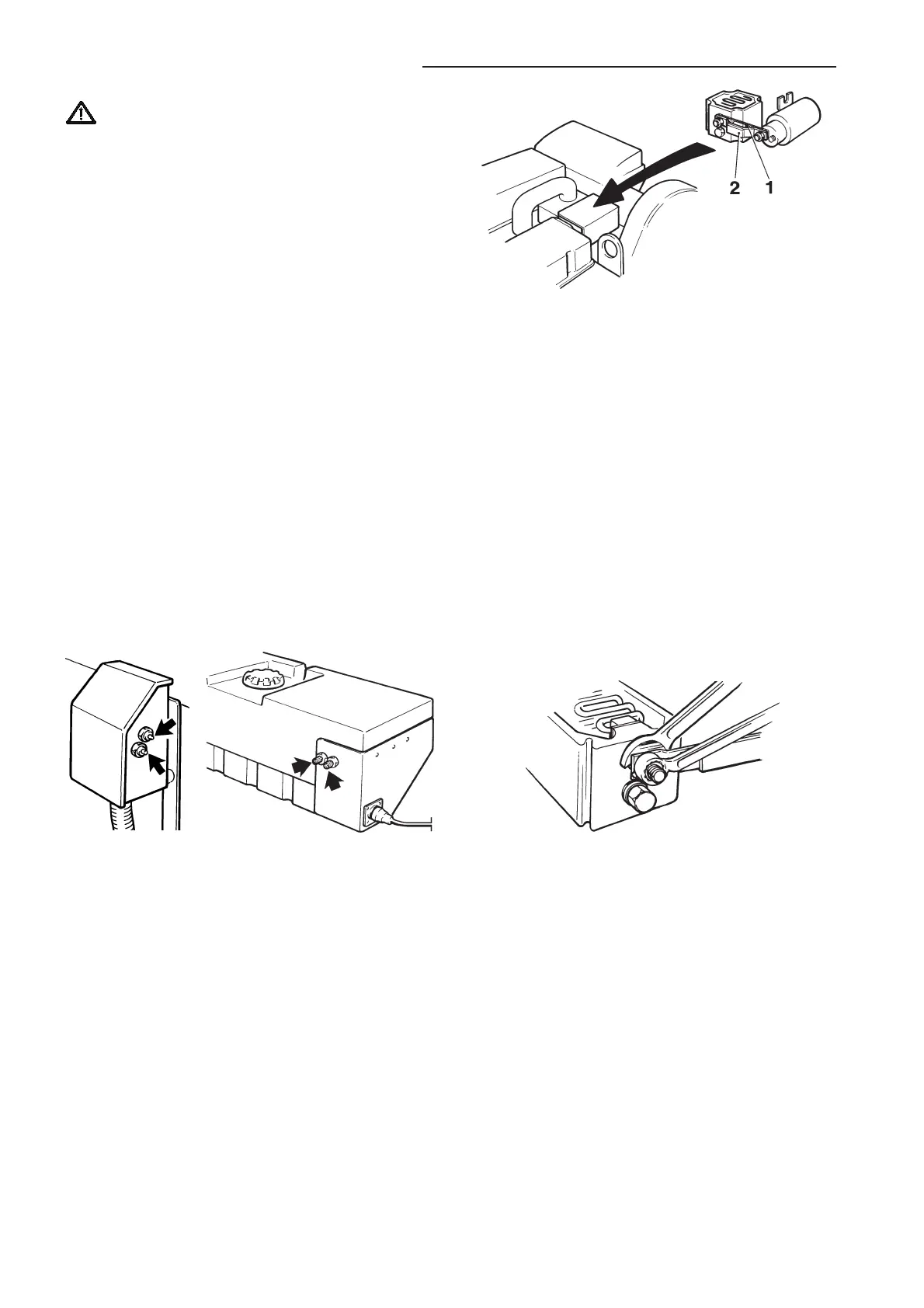

TAMD63, TAMD72P TAMD71, TAMD72WJ

Terminal box with semi-automatic fuses

Blade fuse (1) with support (2) for electrical starter el-

ement

3. Remove the old fuse (1) complete with holder (2).

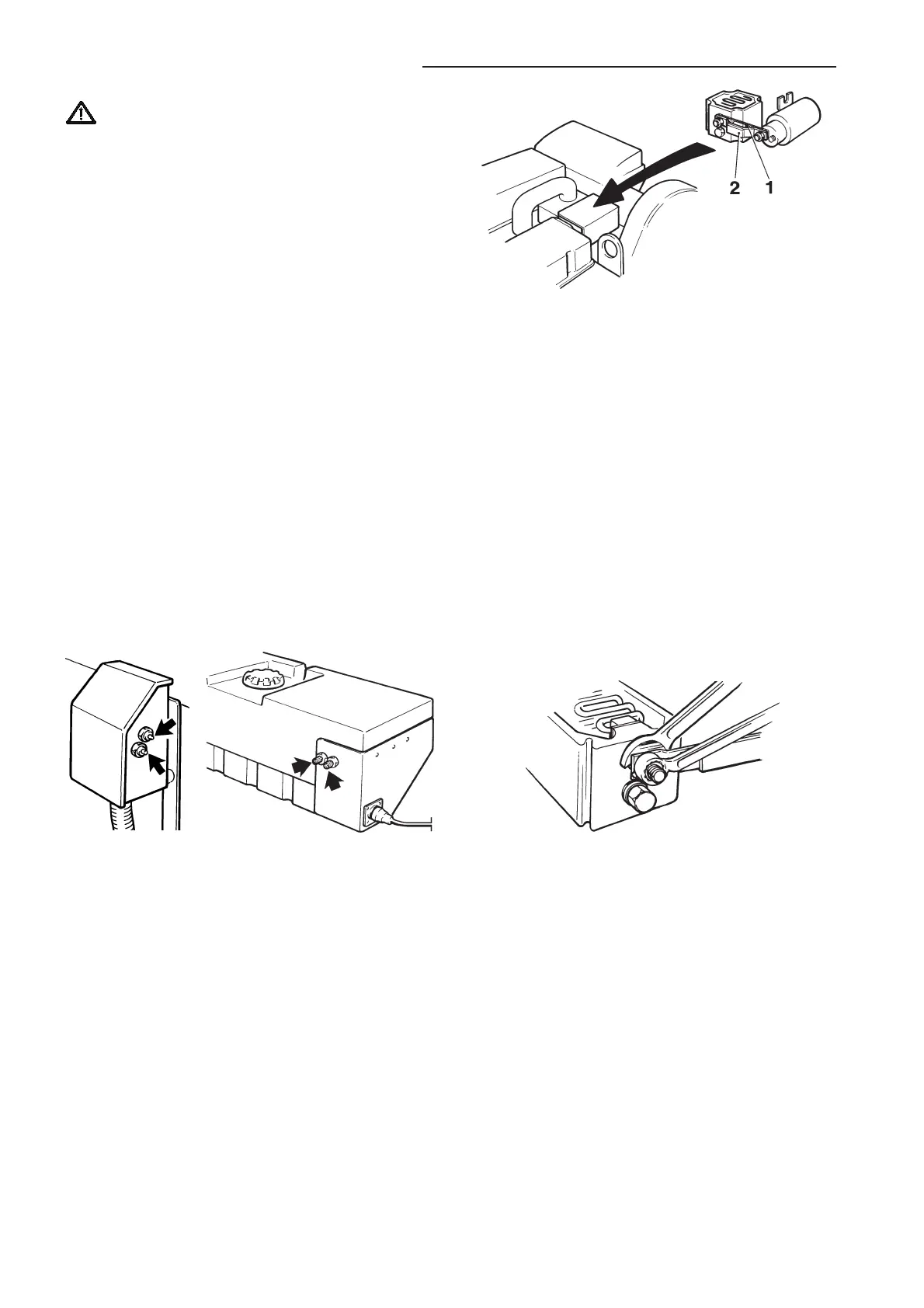

Important! When removing and tightening the

nuts* on the terminal screws on the starter ele-

ment always use a counterhold on the terminal

screws (see illustration). Otherwise, the wire ele-

ment may twist inside the starter element and

cause a short circuit.

4. Fit the new fuse and support as shown in the il-

lustration. Reinstall the cover plate over the relay.

*Tightening torque for terminal nuts = 11–14 Nm (1.1–1.4

kpm/8–10 ft.lb.).

Blade fuse for electrical starter element*

Note: This work should be left to authorized ser-

vice personnel.

1. Stop the engine and break the circuit using

the main switches.

2. Remove the cover plate over the high power re-

lay.

*Note! Applies to TAMD71 engines.

Stop solenoid fuse*

1. Stop the engine and break the circuit using

the main switches.

2. Detach the terminal box and pull it out.

3. Dismantle the fuse holder and replace the fuse

with a new one (16A for 12V, or 8A for 24V sys-

tem voltage). See illustration on next page.

4. Reinstall the terminal box.

*Note! TAMD71 and TAMD72WJ.

Removal/tightening terminal nuts on starter element

terminals

Loading...

Loading...