IMPORTANT!

To

ensure good mat contour fit, mat density of the first

layers must not exceed 1075 g/m

2

(31.7 oz/yd

2

). Alter-

native directed fiber mats (not CSM) of density less

than 1500 g/m

2

(44.3 oz/yd

2

) may be used in the other

layers as long as minimum requirements for number of

layers, total density and total mat thickness are met.

IMPORTANT!

Secondary bondings must be avoided for the lamina-

tion, see General page 51.

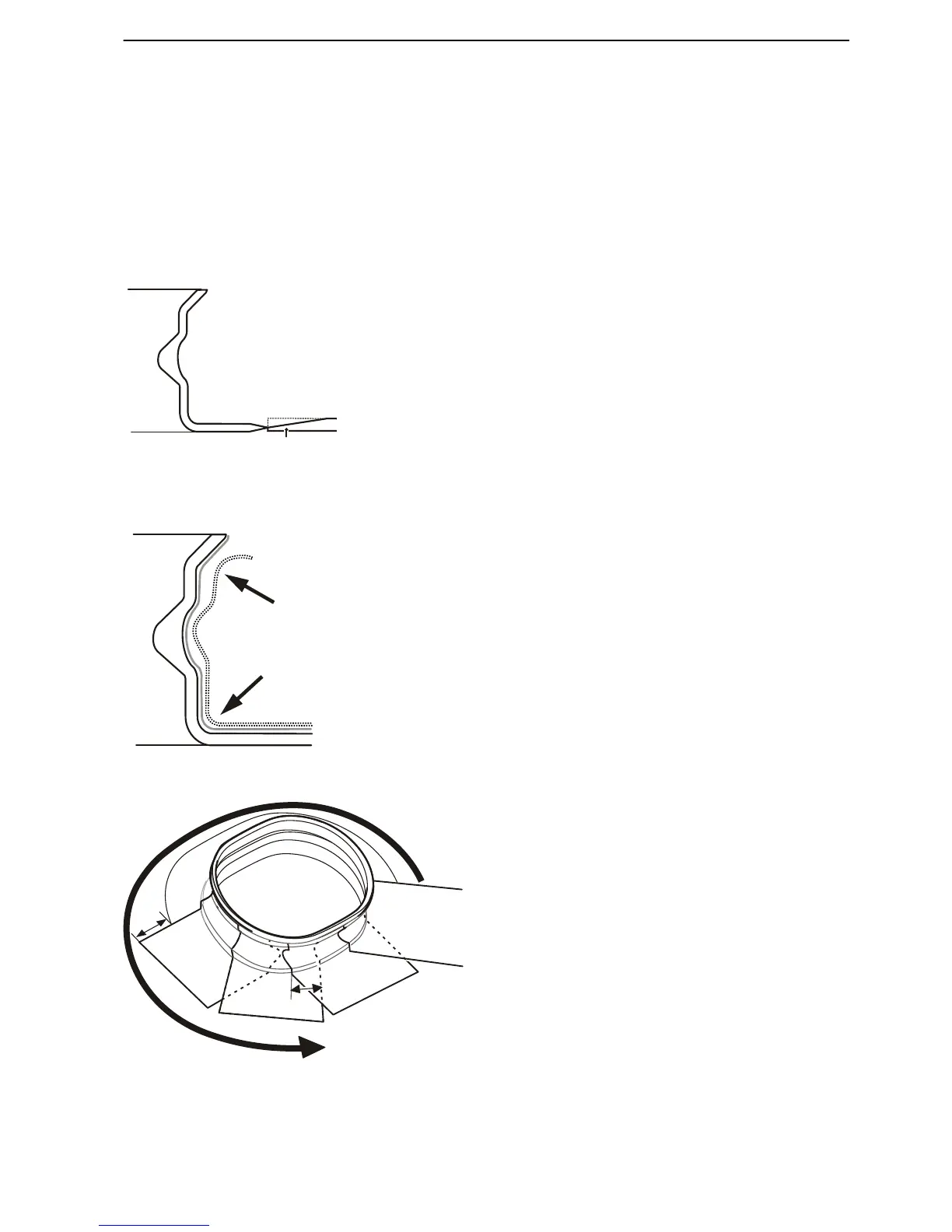

Grinding

Grind a wedge in the hull so that the hull thickness

drops off to the insert. Slope, approx: 1:12. Make the

lamination fill up the recession, following the steps

below.

The bonding surfaces of the pre-molded ring must be

lightly grinded (even if it is already grinded when sup-

plied from Volvo Penta) and cleaned from surface con-

taminates before it is used.

Mat contour fit

Mats must strictly fit the contour of insert. Extend mats

up to top of insert.

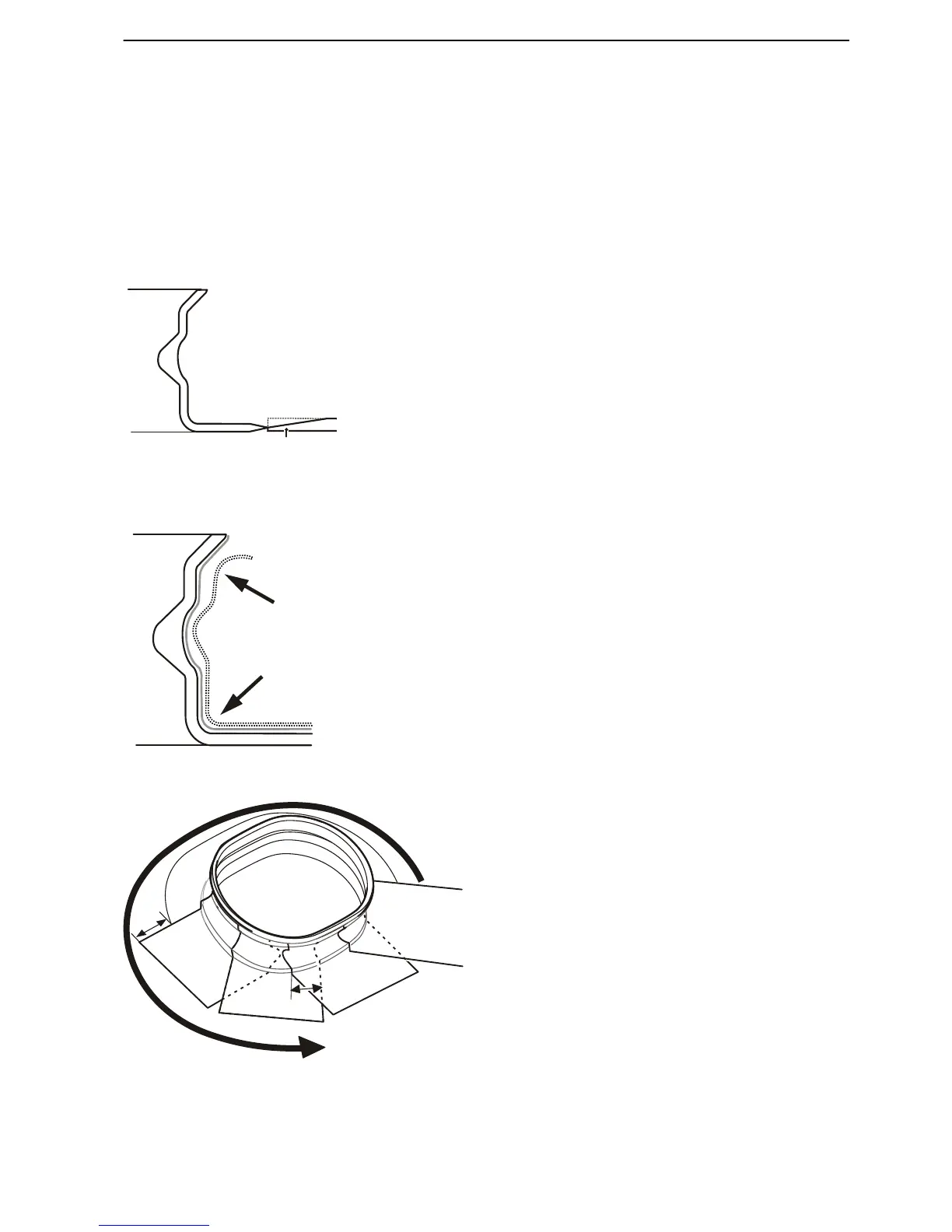

First layer

Place mats around the inserts, that are extended (A)

100 mm (4”) from insert transition onto the hull. A mat

overlap of minimum 50 mm (2”) on the insert must be

applied.

NOTICE! Transom thickness requirement, same as

bottom, applies 600 mm (24”) from bottom and up. It

can therefore be useful to extend aft insert mats.

Loading...

Loading...