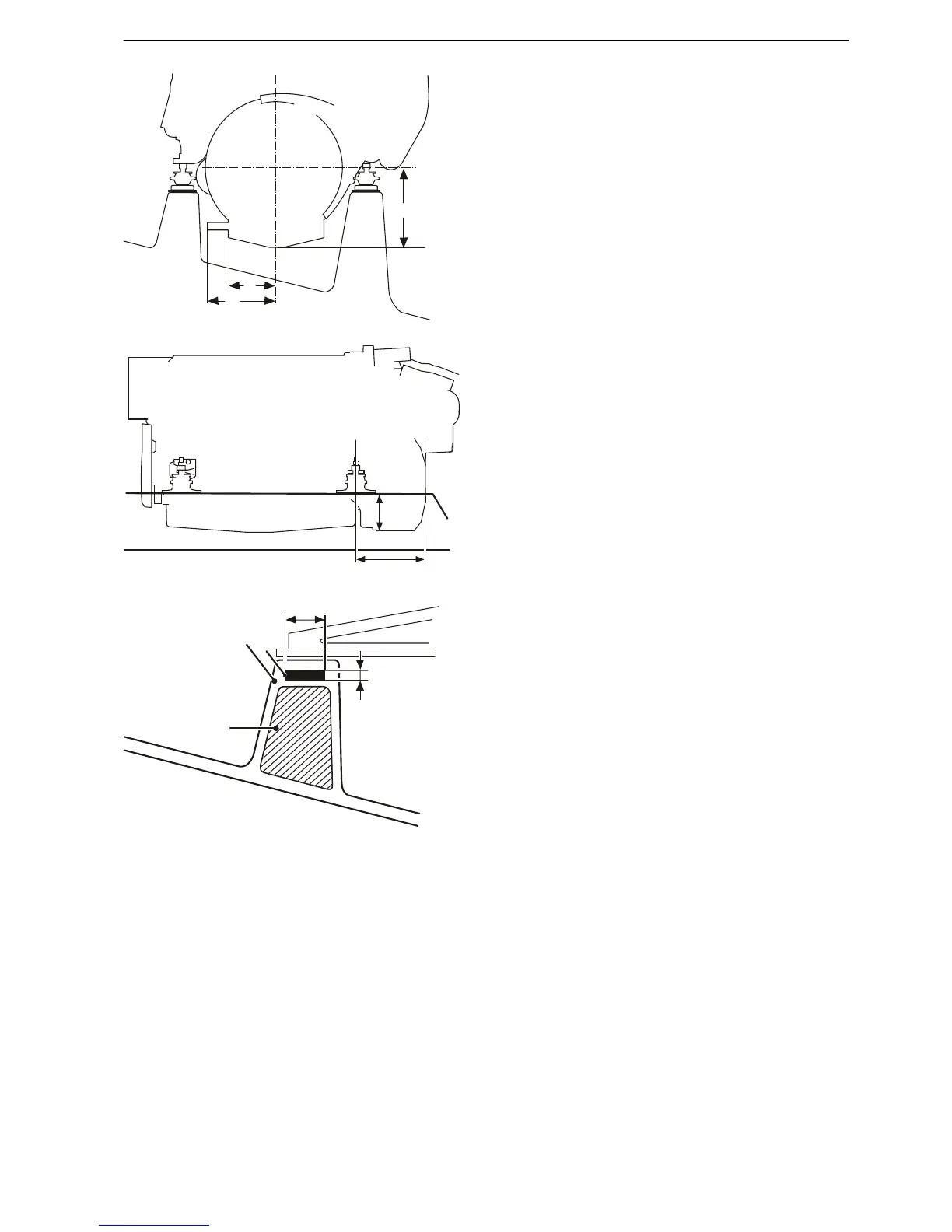

Engines should have a clearance of at least 20 mm

(3/4").

Make sure to leave space for protruding parts.

A 303 mm (11.92")

B 182 mm (7.16")

C Oil level sensor (option): 260 mm (10.24")

D 169 mm (6.65")

E Flywheel housing: 213 mm (8.39")

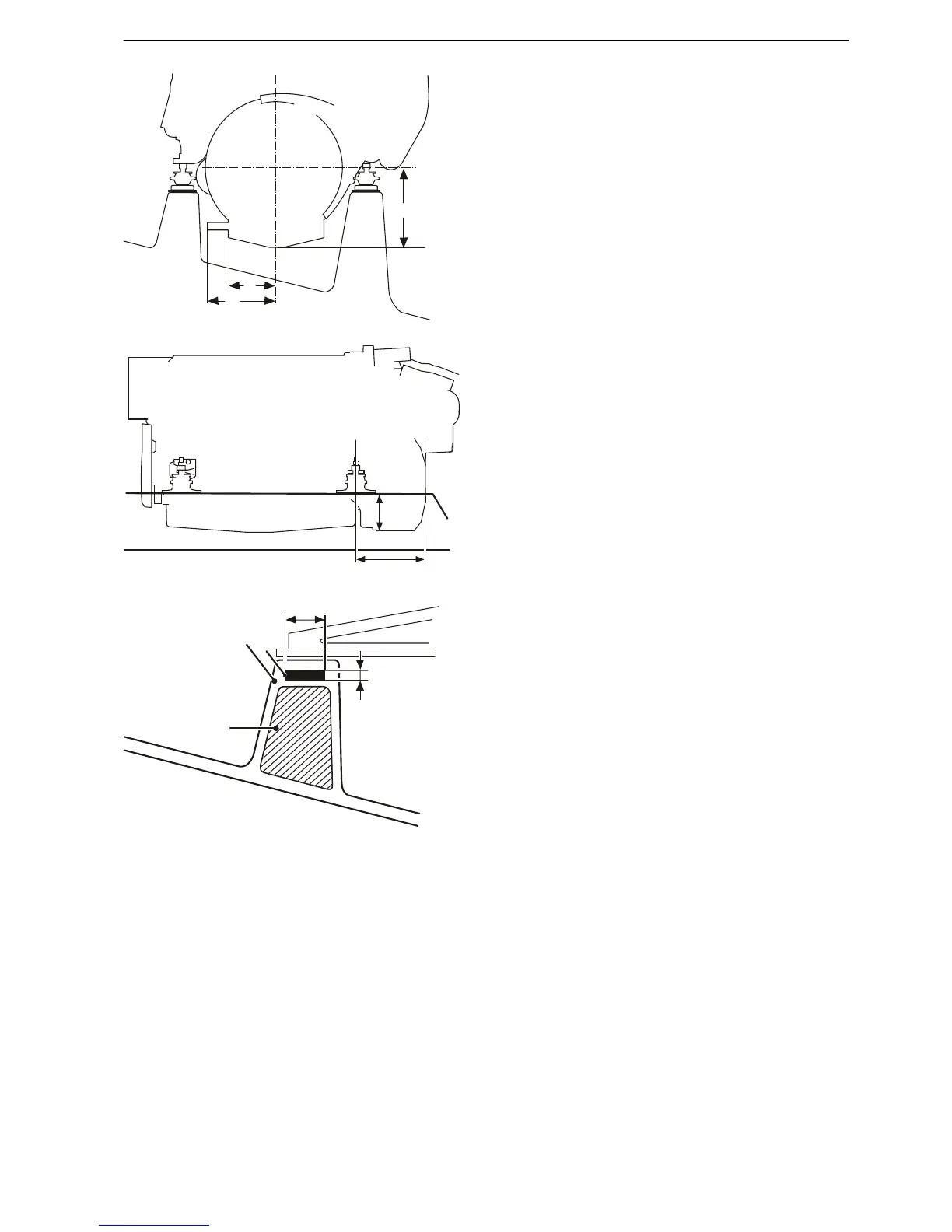

Construction

Build up the bed until it touches the drilling jig along the

entire length of the stay.

Use a suitable core material and laminate according to

current standards (e.g. ISO 12215). Build a galvanized

iron strip into the laminate for the engine mounts. Also

build in drainage channels so that bilge water is able

to run down to the bilge pump.

1 Core material

2 Fiber glass

3 Iron strip

A min 80 mm (3.1")

B 10 mm (0.4")

Holes for engine mounts

Fit the pins for the special tool in the forward and aft

engine mount holes for the engine model concerned.

Slide the drilling jig so that it contacts the pins. Drill 6

mm (1/4") pilot holes through the tool drill bushings into

the bed.

The outer holes are for D13 engines, the inner for D11

engines.

Installation, Volvo Penta IPS

47704162 10-2014 © AB VOLVO PENTA 85

Loading...

Loading...