Transport

FX85, FX110, FX140

Skidding Winch

40

7.4.1 Alternate Method

This method can be used if the two sections of the PTO shaft

cannot be put close enough together to measure.

1. Attach the machine to the tractor three-point hitch.

For instructions, see Attach to a Tractor on page 34.

2. Start the tractor.

3. Raise the three-point hitch off the ground until the machine's

input shaft is level with the tractor's PTO output shaft.

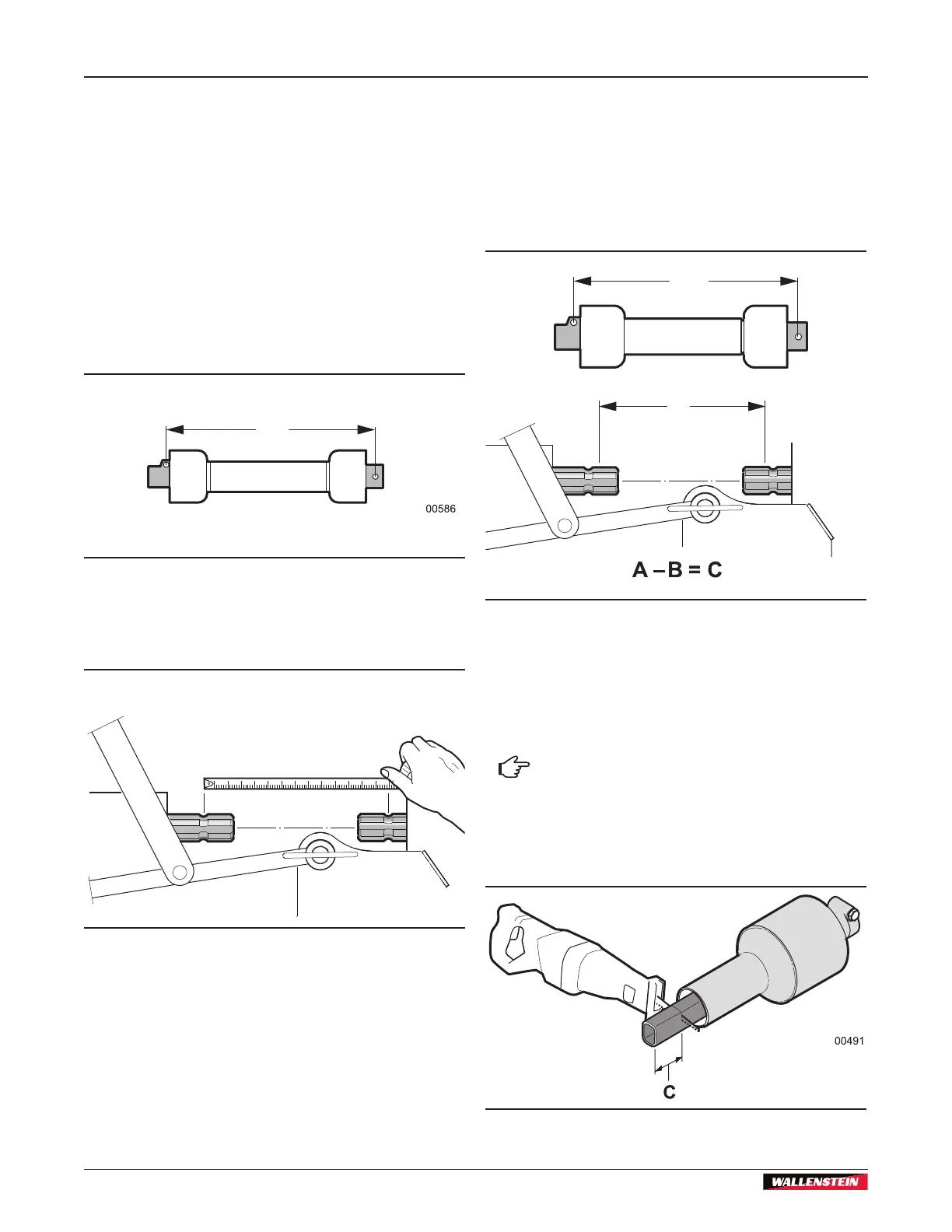

4. Take the PTO shaft that came with your machine, fully

collapse it, and measure the distance between the locking

yokes.

Call this measurement A.

A

Figure 44 – Measurement A

5. Measure the distance between the grooves for the locking

collars on each input. Subtract 2 inches (50 mm) from this

measurement. Call this measurement B.

L – 2" (50 mm) = B

00944

L = ?

Figure 45 – Measurement B

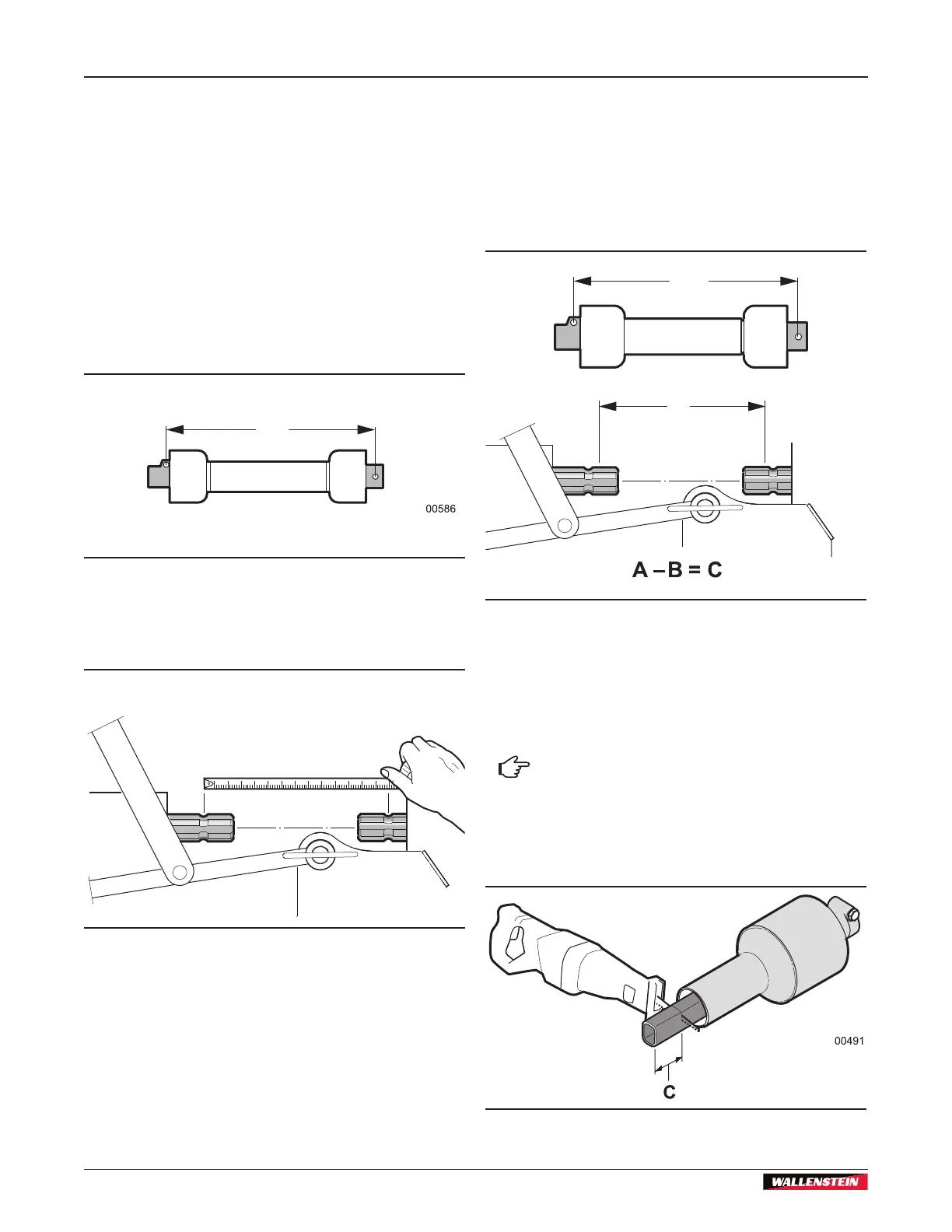

6. If the collapsed length A is longer than measurement B from

Step 5, the PTO shaft must be shortened.

7. Subtract B from the uncut PTO shaft measurement A. (A –

B)

The result is length that both sections of the PTO shaft need to

be shortened. Call this value C.

A – B = C

00945

A

B

(L - 2 inches)

(L - 50 mm)

Figure 46 – C = Cut length

8. Separate the PTO shaft into two sections.

9. Measure and cut the length C from the outer plastic covers

and the inner metal tubes of each section.

Tip: Use the cut piece of outer shielding to mark

the inner tube. Leave the steel center tubes longer

than the plastic outer tubes, otherwise they can be

harder to assemble.

Figure 47 – Cut the length C from both PTO shaft sections

Loading...

Loading...