9.0 INFORMATION REGARDING FAULTS

2

FIL.SILOTOP_zero.--.M.A4.0722.EN Issue: A4

07.22

42

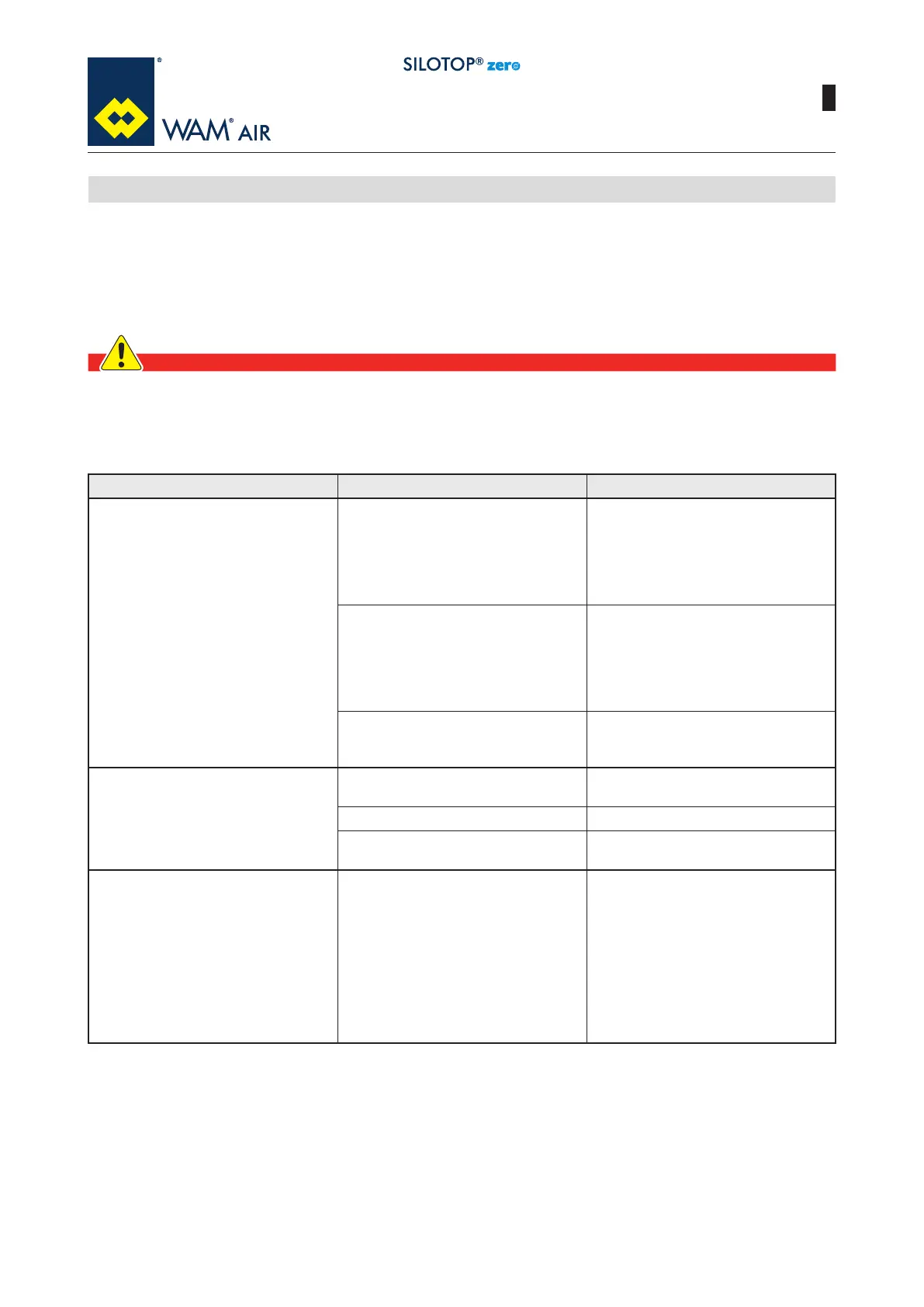

FAULT PROBABLE CAUSE POSSIBLE REMEDY

Excessive dierential pressure.

1) Compressed air supply failure. 1) Check the operation of the

compressor.

Check whether condensate is

present in the lter

Check for water and/or oil inside

the air tank of the lter.

2) No air in the blowing pipes. 2) Check the electronic board

conguration and connection.

Check the if the solenoid valve

works properly.

Check if the solenoid valve

membrane works properly.

3) Filter elements clogged. 3) Run the lter on empty and then

remove all lter elements and

replace the damaged ones.

Dust in the clean area.

1) Check for possibly damaged lter

elements.

1) Replace if damaged.

2) Check the seals. 2) Replace if damaged.

3) Check if the lter elements are

housed correctly in their seat.

3) Repeat installation if necessary.

Continuous blowing of the solenoid

valve.

1) Check if the coil works. 1) Switch on and o the compressed

air supply to the lter 3-4 times.

2) Remove the coil (6) after removing

the relative ring nut. Unscrew the

component (5) ensuring that the pin

and spring inside does not fall and

that the former slides perfectly in.

3) Inspect thoroughly the in coupling

area of items (4) and (5) making

sure there are no impurities.

9.1 Trouble-shooting

Minor problems can be solved without consulting a specialist.

The following Table contains a list of the most common problems, the possible causes and possible remedies.

For particularly dicult actions which are not mentioned in the Table, contact the Manufacturer’s Customer

Service Department.

Before carrying out any operation “set the equipment (machine) concerned in safety” (see “Glossary

and terminology”), operate according to the indications on the “Operation and Maintenance Manual”

and in accordance with and in compliance with the standards in force as regards health and safety.

Loading...

Loading...