5.0 INSTALLATION AND FIXING

2

FIL.SILOTOP_zero.--.M.A4.0722.EN Issue: A4

07.22

22

The compressed air must be:

1) Clean: with no residues that might damage the lter.

Danger - Warning

Drain the piping prior to connecting the compressed air to the lter.

2) De-moist- The air tank is provided with a condensate drainage tap. The user should provide for a conden-

sation separator.

3) Oil-free -The presence of oily substances in the air could cause premature and irreversible clogging.

Use only lters that maintain the air always clean and oil free.

Tank inlet pressure

- Minimum 4 bar

- Maximum 6 bar

Variations in the conditions of use could require:

- Modications of inlet pressure to the tank

- Modications to the electronic board settings, which therefore vary the compressed air consumptions.

It is recommended to install a Kit (pressure gauge, air/oil pressure reducer) near the lter. A manual On-O

device (ball valve or similar) must be inserted on the air supply line to facilitate the maintenance operations.

The required air quality must be equal to or over class 4 according to ISO 8573-1.

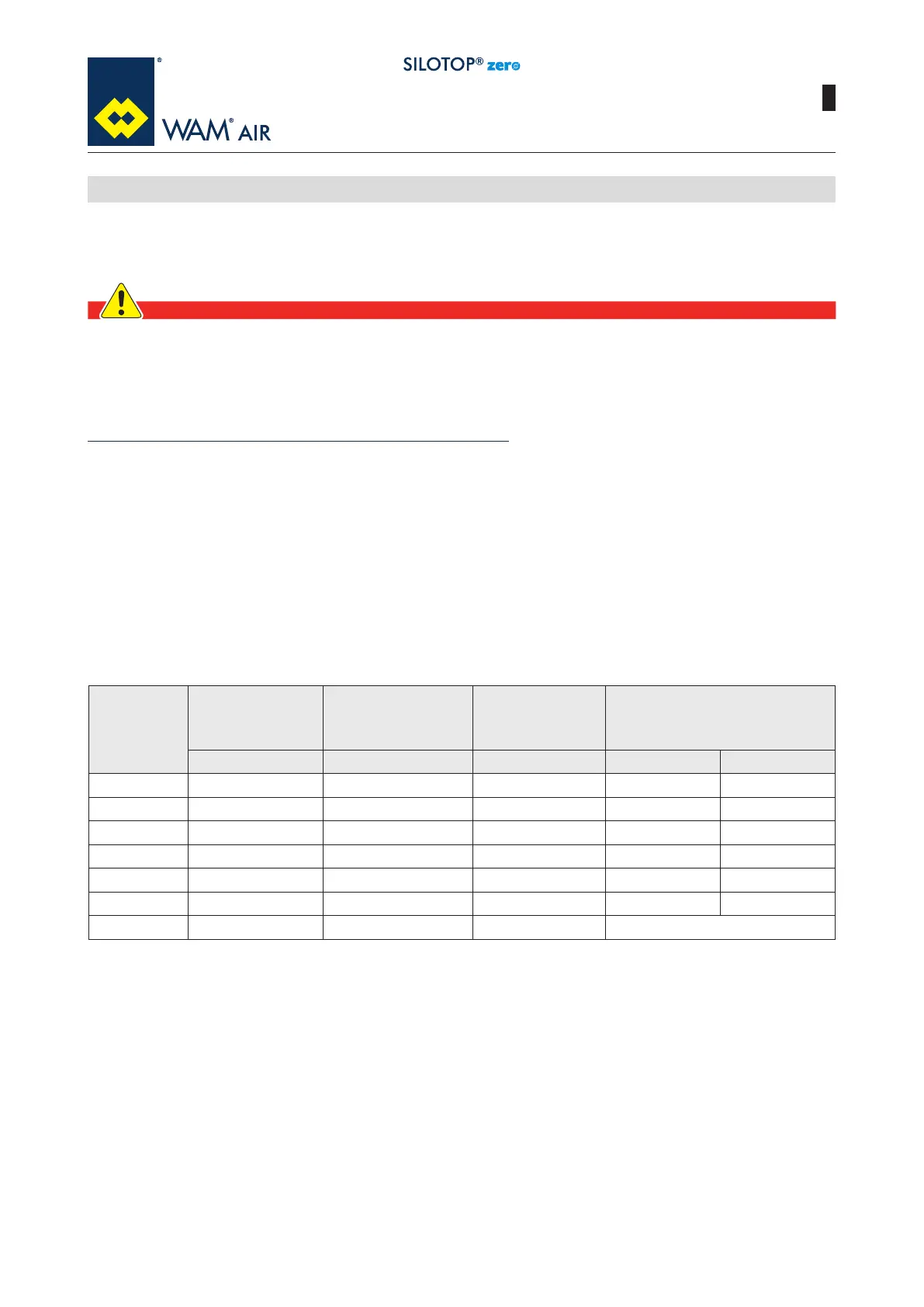

5.5 Pneumatic connection

Class

Maximum oil

concentration

Maximum

particle

size *

Maximum

concentration **

Maximum

condensation

point under pressure

(mg/m

3

) [µm] (mg/m

3

) °C °F

1 0.01 0.1 0.1 -70 -94

2 0.1 1 1 -40 -40

3 1 5 5 -20 -4

4 5 15 8 3 37.4

5 25 40 10 7 44.6

6 -- -- -- 10 50

7 -- -- -- Not Specied

* The particle size depends on the ltration ratio ßµ = 20.

** At 1 bar (14.5 psia), 20°C (65°F) and a relative vapour pressure of 0.6 (60%).

Loading...

Loading...