19

SETUP

3.5 Adding Filament

1. Clean off any excess lament residue from the tip of the nozzle using the scraper

2. Enter the main menu and select Quick Settings Move Home XYZ to move

the nozzle to the home position in the front right corner

NOTE: Immediately turn off the machine any motors are jamming pr forcing against the chassis.

3. Select back Disanle steppers to enable movement of the print bed and extruder

4. Manually move the print bed and extruder to each corner or area you would like to level

5. On each corner, turn the relevant thumbwheel until you can just slide a piece of copy paper

between the extruder and print bed with slight resistance,about 0.1mm

6. Continue checking points on the print bed until you are satised it is level

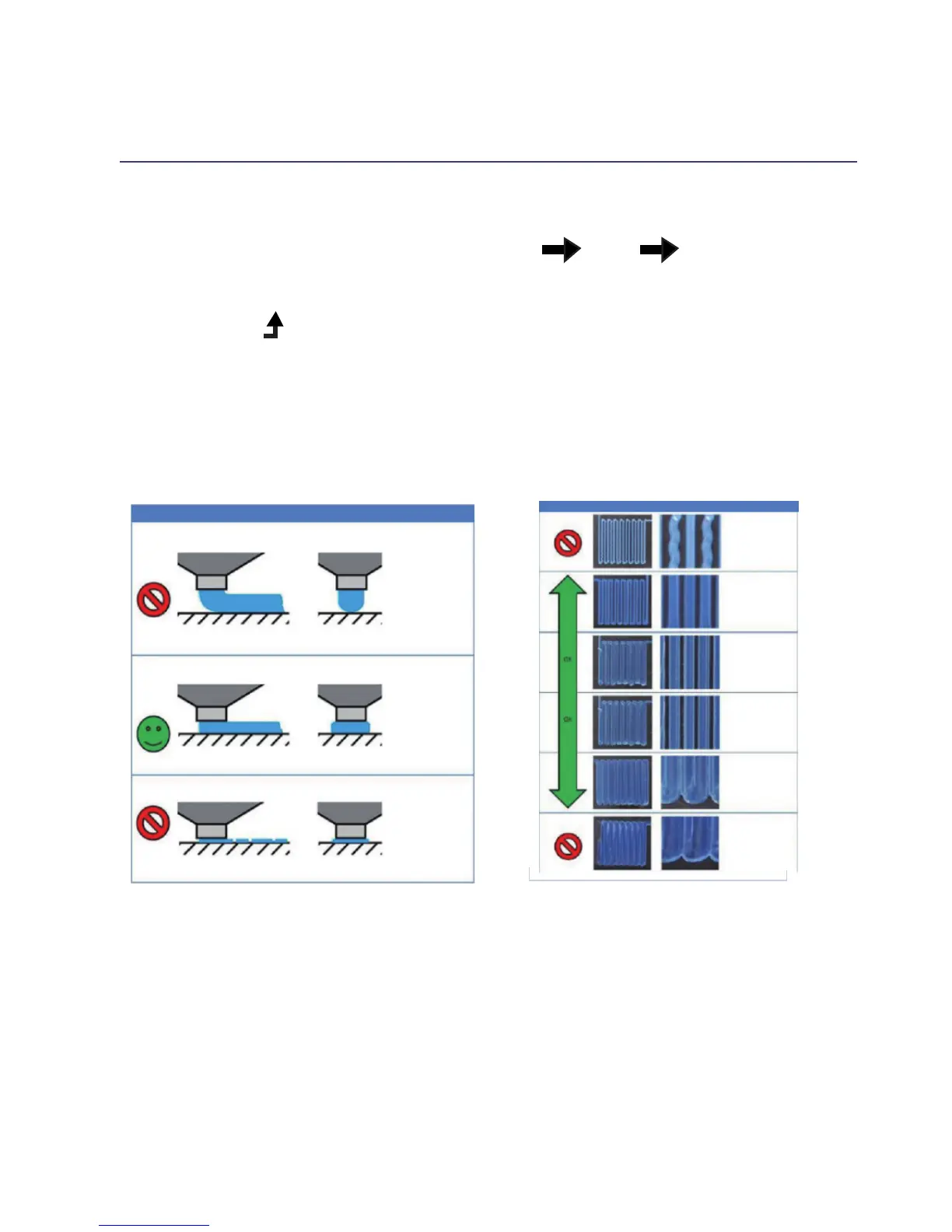

SIDE VIEW END VIEW COMMENTS

Nozzle Too High:

Insufcient contact

area resulting in

poor adhesion and

extrusion skipping.

OK:

Filament pushed

into the build

surface slightly to

maximize surface

area contact while

still allowing good

extrusion ow.

NOZZLE TOO LOW:

Not enough

clearance for the

lament to be

extruded... this will

result in damage to

the extruder and/or

build surface.

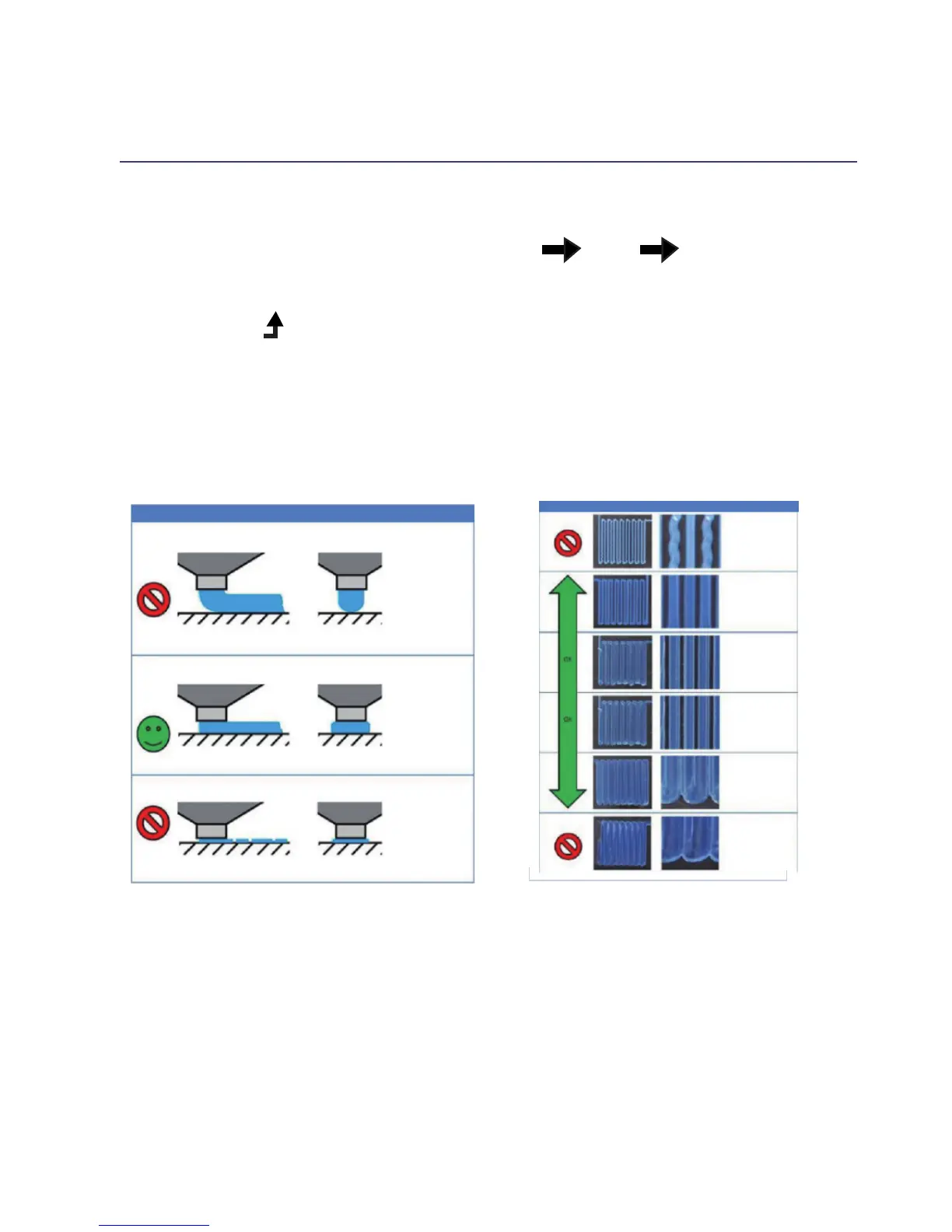

RAFT

MAGNIFICATION NOTES

NOZZLE TOO HIGH:

Wavey tracks,or tracjs

narrower than 1.2mm

(use vernier callpers

to check)

NOZZLE TOO LOW:

Trancks sides pushed

over neighbouring

tracks.

CHECKING CHART

If you are new to 3D Printing we highly recommend that you visit our website to review our

video tutorial on levelling the print bed at https://www.wanhao3dprinter.com

Loading...

Loading...