Section 4

Auto-Zone CV & CV-EX

4-28 Start-Up and Troubleshooting

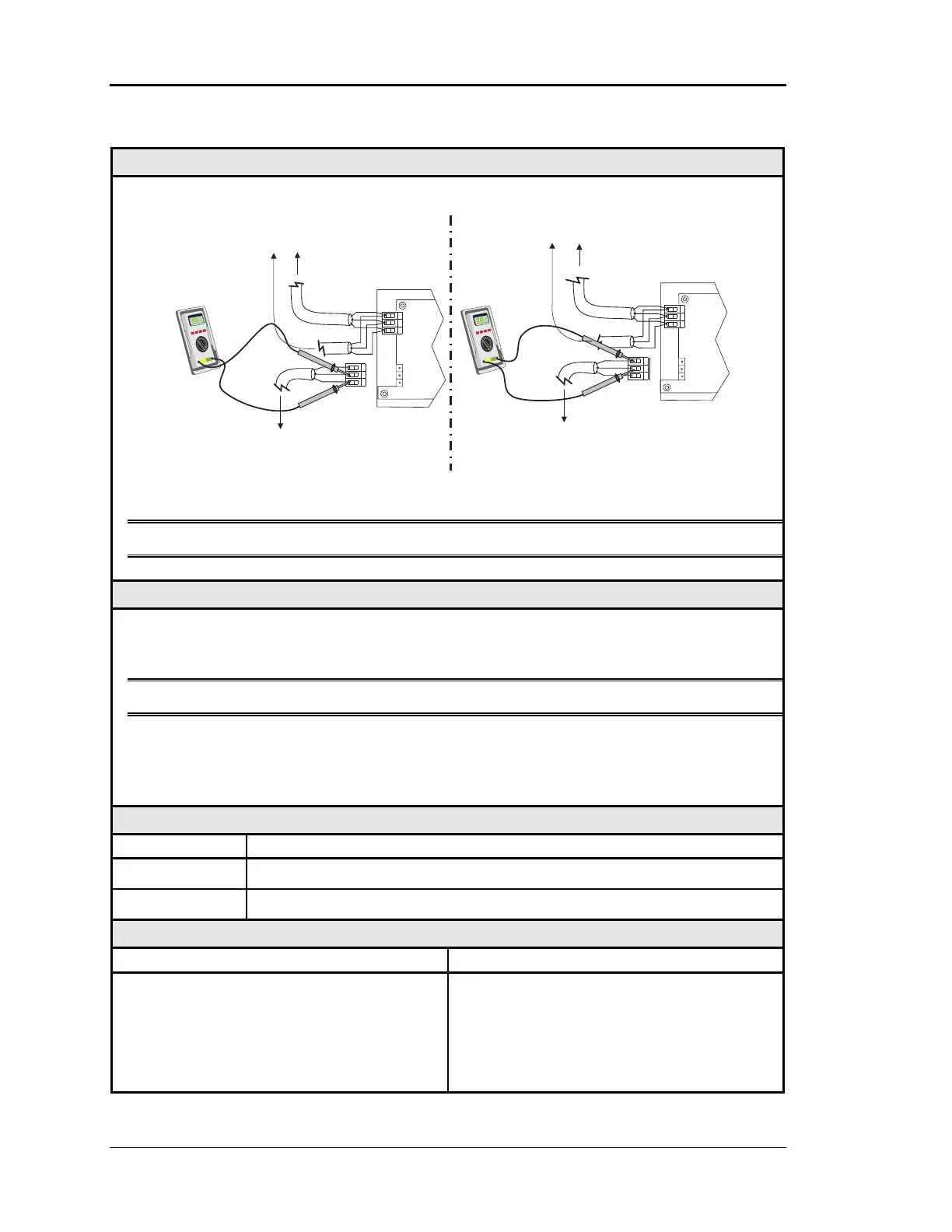

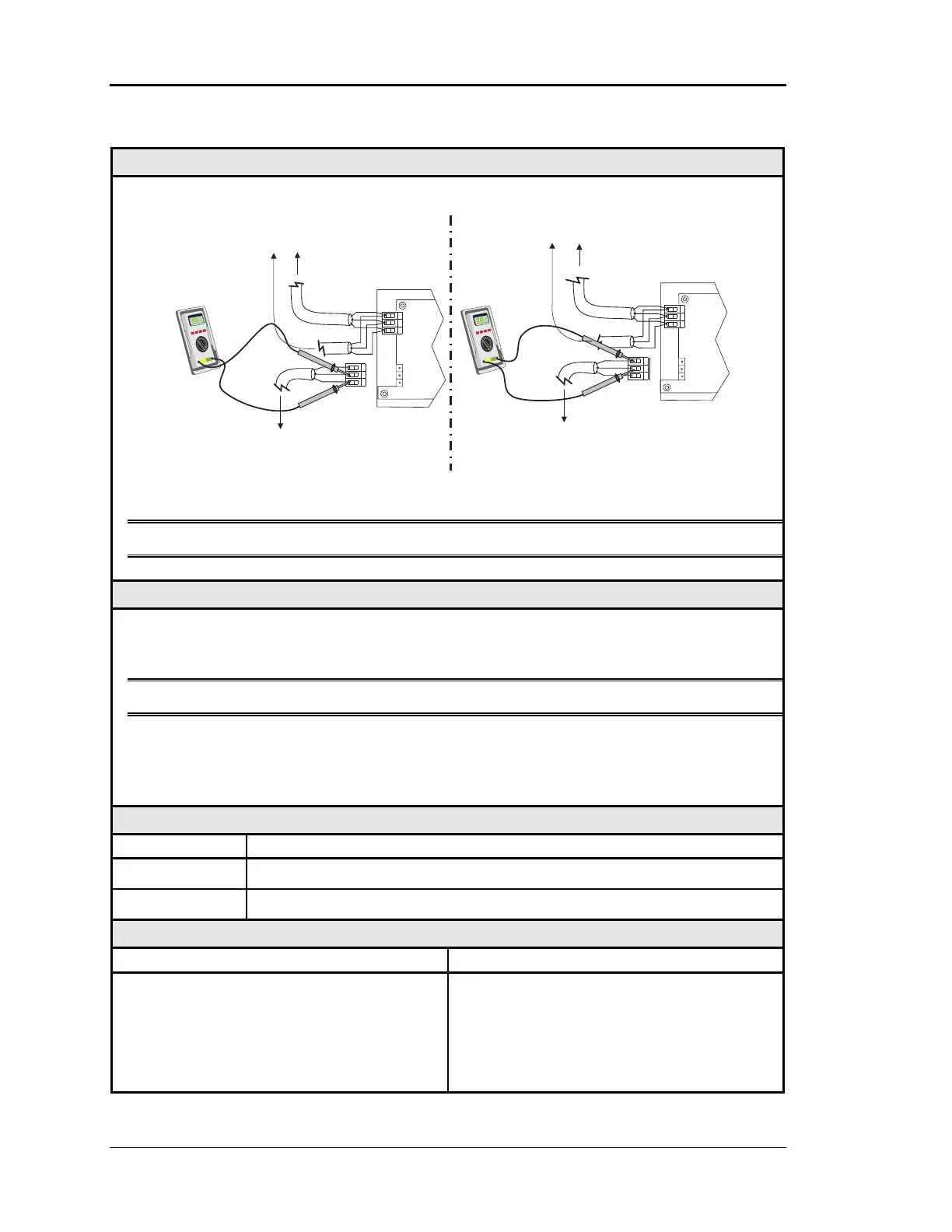

Checking the Local Loop at the MiniLink – CV-EX

Diagram

Meter Set To Read DC Volts

NETWORK

LOOP

G

T

R

G

G

G

T

T

T

R

R

R

+

-

+

-

+2.4 VDC

to

+2.5 VDC

R-to-G

T-to- G

NETWORK

LOOP

G

T

R

GT

R

+

-

+

-

+2.4 VDC

to

+2.5 VDC

To Other MiniLinks

Or CommLink

On The Network Loop

To Other MiniLinks

Or CommLink

On The Network Loop

MiniLink

MiniLink

To CV Controllers

And System Manager

On Local Loop

To CV Controllers

And System Manager

On Local Loop

The indicated values are typical of a normal system. Actual readings may deviate slightly

due to the number of units connected and other system specific factors

Note: These tests assume that the MiniLink being checked are powered up.

Overvie

This is a “quick check” to determine if any of the CV Units on a Local Communications

Loop are damaged. Since all CV Units will “float” their communications connections at

about 2.45 Volts, you can quickly check an entire loop by unplugging it at the MiniLink.

Note Be sure that the loop you are testing does not have a short circuit from T - R.

Damage typically occurs when the communications loop is exposed to excessive voltage, as

may occur during installation, due to wiring errors. The driver chips are socketed on all

boards to facilitate servicing. It is unusual for driver chips to fail during normal operation.

Almost all failures occur due to wiring related problems.

Measurements

Local Loop Acceptable Range

T - SHLD 2.4 - 2.5 Volts DC

R - SHLD 2.4 - 2.5 Volts DC

Action

Condition Action

If voltages are too high or to low on either

side

1. One or more of the attached controllers

has a damaged Comm Driver chip. See

Figure 4-9.

2. Wiring errors such as "crossed connec-

tions", short circuits, etc.

Loading...

Loading...