47

Daily Repair and Maintenance

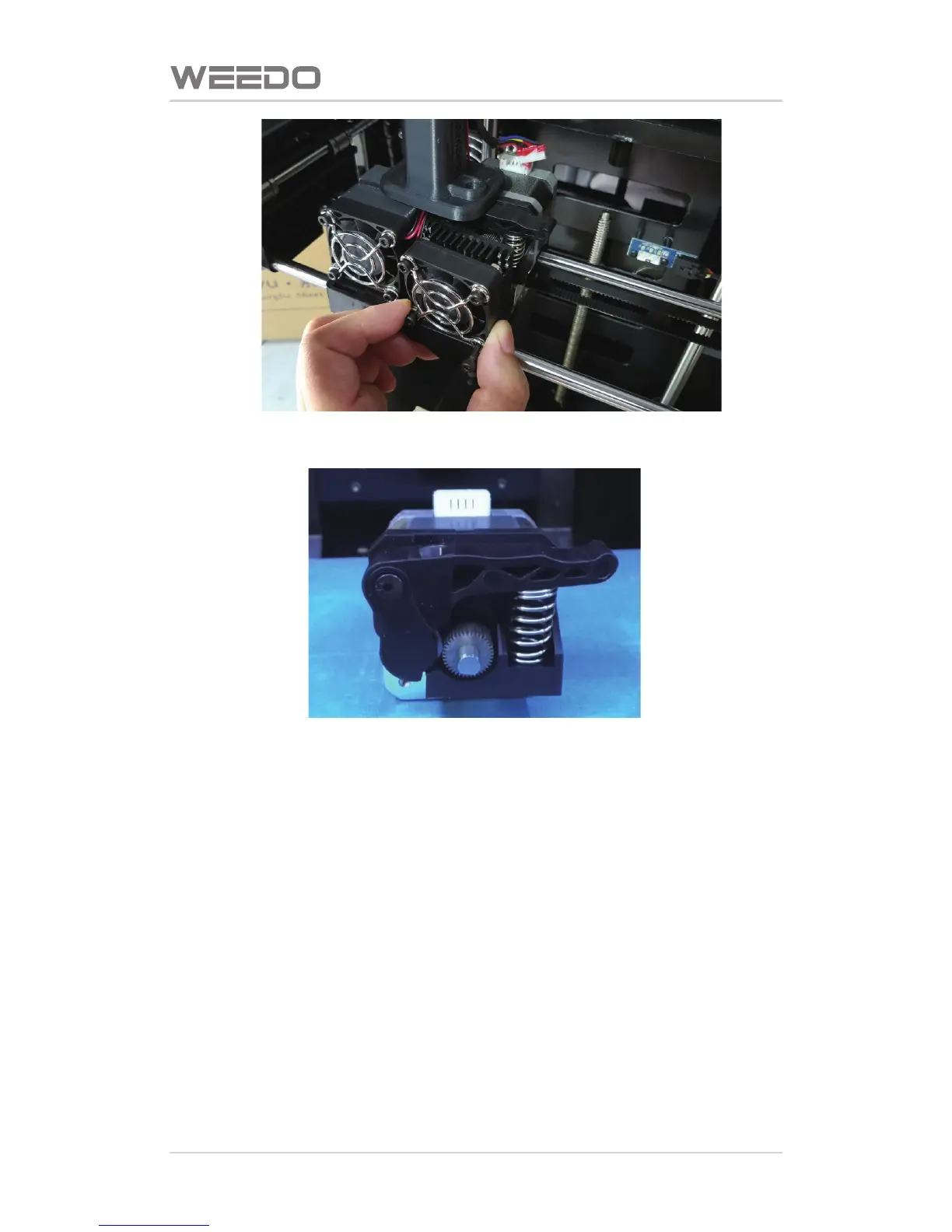

Then, take out the whole motor and feed gear from right back side

The filament debris on the motor gear is performed with cleaning by tweezers,

and installed is performed according reverse procedures aer cleaning.

Note: Finally plug in the motor connecon line.

7.2.2. Replacing Prinng Nozzle

When the operaon is inappropriate or the filament materials is not selected

properly, they would cause nozzle blockage. In the necessary cases, it needs to

perform the nozzle replacement.

Disassembly Procedure:

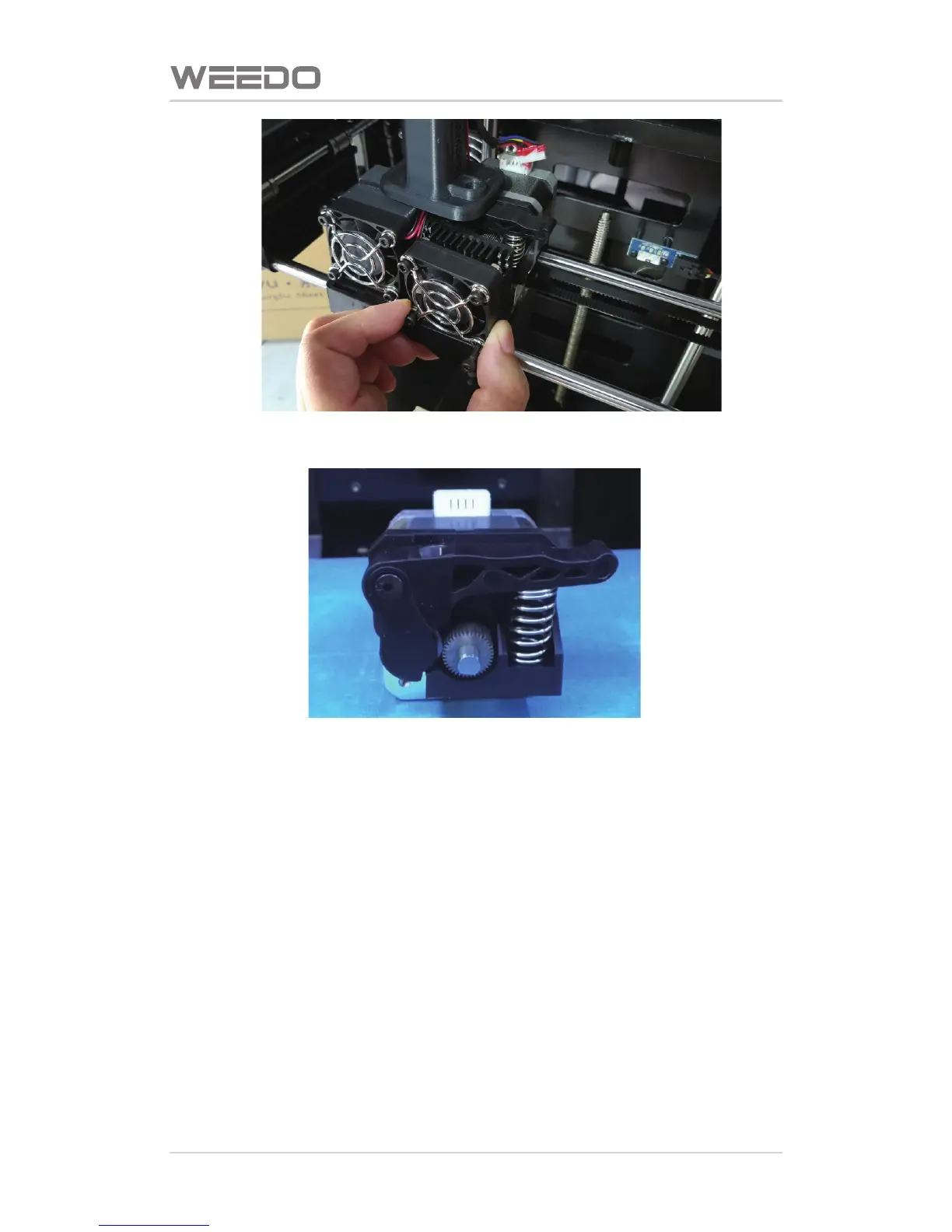

The component of noozle is fixed by a screw behind the fan.

Use 2.0mm hex wrench to lossen the screw, throuth the bloade gap fan.

Loading...

Loading...