E-26 | WG20 Geared Motors

Incorrect work on the gear or motor can lead to damages. Should errors emerge at the gear or gearbox,

the drive has to be stopped immediately!

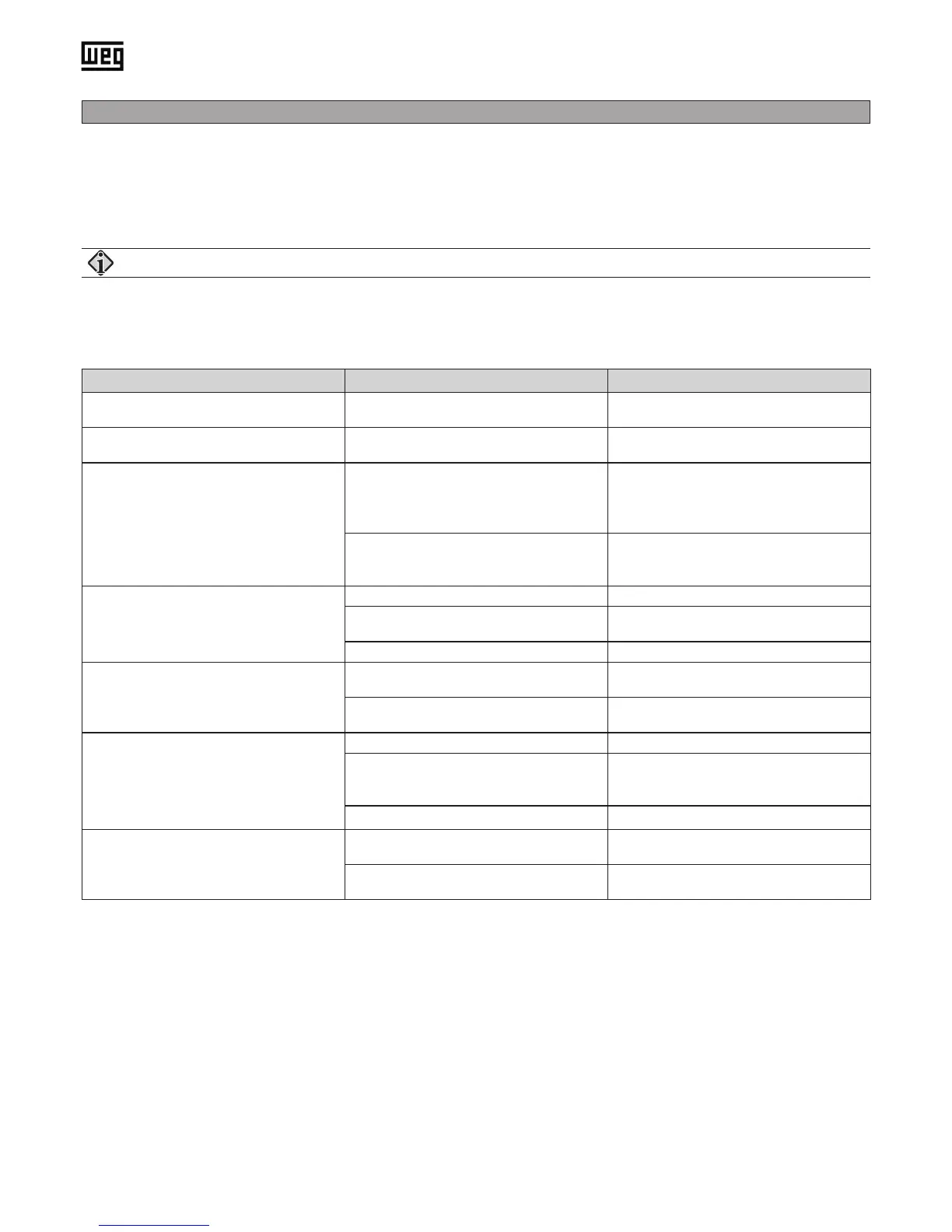

Malfunction Possible cause Settling

Unusual, even operating noise. Bearing damage, gearing damage. Consult the producer.

Unusual, uneven operating noise. Foreign object in the oil. Perform an oil change.

Movement of the gear unit during

switch-on.

Gear unit xation has loosened.

Tighten the xing bolts and nuts with

prescribed screwing torque.

Change damaged xing bolts and

nuts.

Rubber buffer set at the torque sup-

port is not pre-stressed or damaged.

Pre-stress the rubber buffer set cor-

rectly or change the damaged rubber

buffer set.

Gear unit gets too warm (Gear surfa-

ce temp. > 90°C).

Too much oil. Correct the oil lling capacity.

Gear unit damage (gearing, bearing). Consult the producer.

Vent plug is defective. Change the vent plug.

Oil leakage at the gear unit or motor.

Gasket is damaged.

Check gaskets, change them if

necessary.

Gear unit is not ventilated.

Remove the transport lock at the vent

plug.

Oil leakage at the vent plug.

Too much oil. Correct the oil lling capacity.

Gear unit is operated with the wrong

type.

Mount the vent plug at the correct

position. Adjust the oil lling capacity

according to the type.

Vent plug is defect. Change the vent plug.

The gear unit output shaft does not

turn though the motor runs or the

drive shaft is being turned.

Breakage in the gear unit or shaft hub

connection disrupted.

Consult the producer.

Shrink disc connection slips through. Check the shrink disc connection.

Possible malfunctions on the gear unit:

Loading...

Loading...