E-34 | WG20 Geared Motors

18. Optional motor devices

18.1. Anti-condensation heating

18.2. Drain

18.3. Forced cooling

Brake, encoder, temperature controller, anti-condensation heating, forced ventilation, etc. are present only on special order.

Additional devices are to be connected according to the valid wiring diagrams.

Under certain climatic conditions, an anti-condensation heater may be required e. g. when there are great uctuations in

temperature or the motor is at rest in a humid atmosphere. For heater connection, see the motor terminal box.

Before energizing the motor, always make sure that the (optional) anti-condensation heating is switched off.

If motors are subject to great uctuations in temperature or extreme climatic conditions, humid air can condense inside the

machine. We recommend using a drain.

■ Open the drain depending on the environment and operating conditions. Afterwards, close the drain plug.

■ Before installing motors with drain, check that the mounting position is correct!

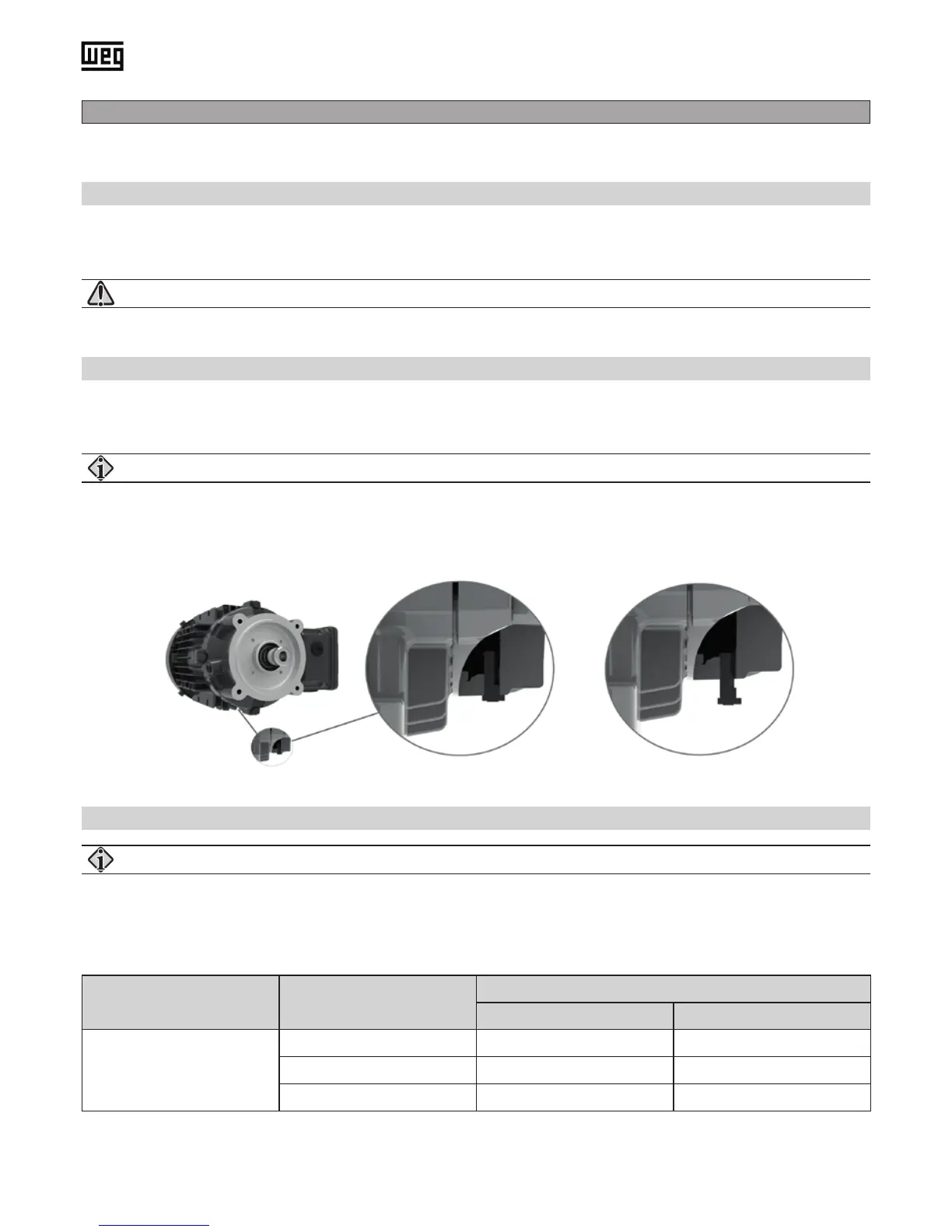

Figure 13: Detail of the drain plug position on drive endshield

■ The forced cooling must be connected according to the wiring diagram below (see also in forced cooling

terminal box).

■ If the motor is operated with a frequency inverter, it´s not allowed to connect the forced cooling to the frequen-

cy inverter. Connect the forced cooling to an EXTERNAL power supply.

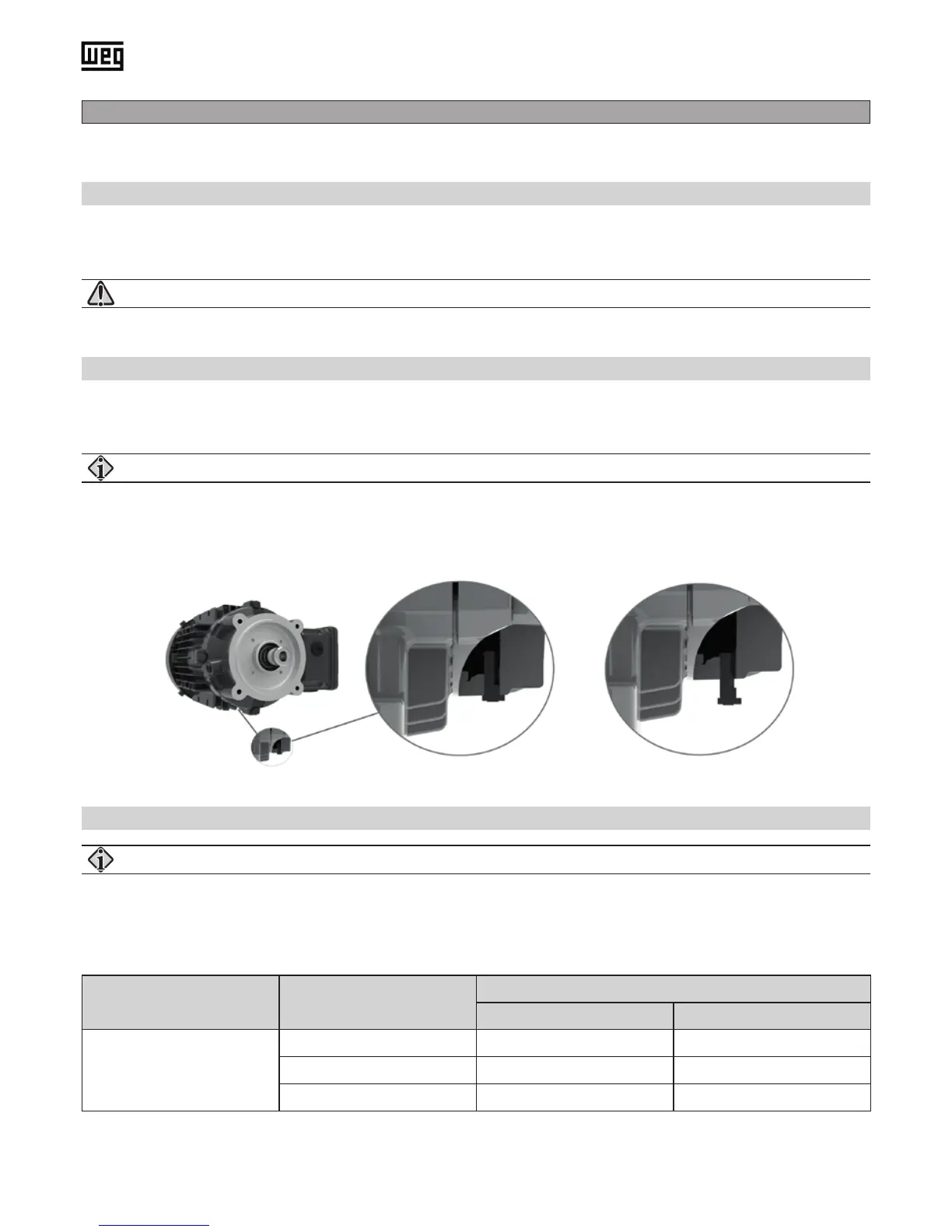

IEC frame size Phases / Connection

Voltage range [V]

50 Hz 60 Hz

63 - 180

3~ / Star 346 - 525 380 - 575

3~ / Delta 200 - 303 220 - 332

1~ / Delta Steinmetz 230 - 277 230 - 277

Loading...

Loading...