E-8 | WG20 Geared Motors

5. Storage

General:

The following items must be taken into account when storing the gear units:

■ In general, the drive units must be stored in closed rooms.

■ Ambient temperature max. 25 °C (77 °F)

■ Relative humidity max. 80 %

■ The drive units are to be protected from exposure to the sun or UV light.

■ No aggressive or corrosive materials are to be stored in the vicinity of the unit.

■ The gear units are to be stored in the same position that is intended for a later use.

■ The gear units are to be rotated 1-2 revolutions on the output side every 6 months to ensure that the interior parts are

wetted with lubricant.

■ The units are to be protected from mechanical loads and exposure to outside forces.

Long-term storage:

■ When the gear units are to be stored for longer than 12 months, they must be completely lled with lubricant as stated

on the nameplate or lubricant plate.

■ Unnished, bare-metal parts on the outside of the unit are to be protected with a corrosion protection product

(inspection every 6 months is recommended). The corrosion protection must be replaced after one year.

■ Before starting the gear unit, drain the lubricant from it. If more than one lubricant chamber is present, make certain that

all of the lubricant chambers have been drained out.

■ Gaskets settle, especially after a longer period without loading. Before starting, the screws must be retightened.

■ Then ll the gear unit with the lubricant type specied on the nameplate using the specied quantity.

■ If the gear units are stored for longer than 24 months before being put into service, they must be checked for leaks.

If there are any visible cracks on the surfaces of sealing elements, such parts must be replaced.

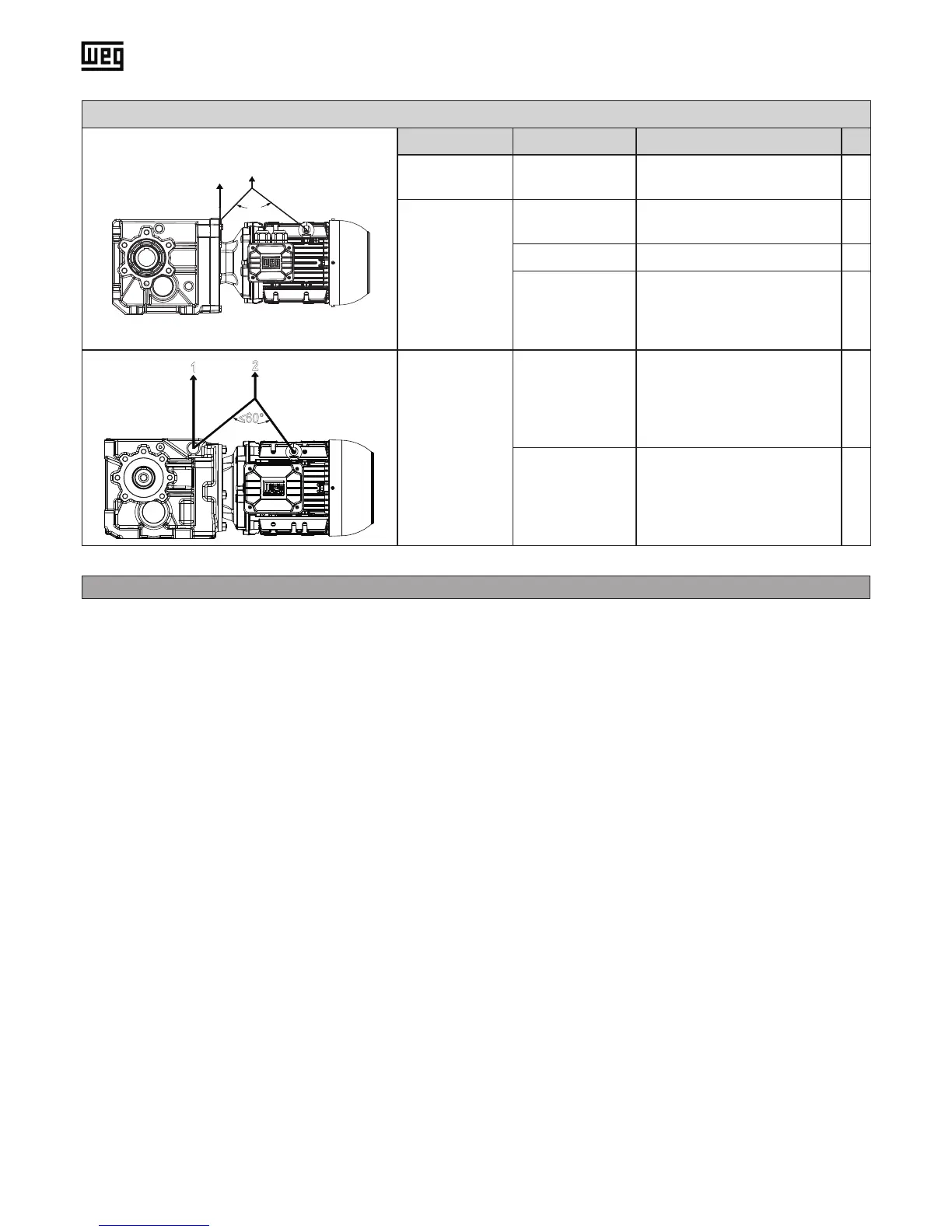

Helical bevel geared motors K

<

60°

1

Gear size Motor size Load handling

K02 all

No equipment for load

handling provided

-

K03

K04

K05

63 - 71

No equipment for load

handling provided

-

80 - 90 Lifting eye on the gearbox 1

100 - 132

Lifting eye on the gearbox

+ eye bolt on motor

(max. angle of 60° between

the ropes)

2

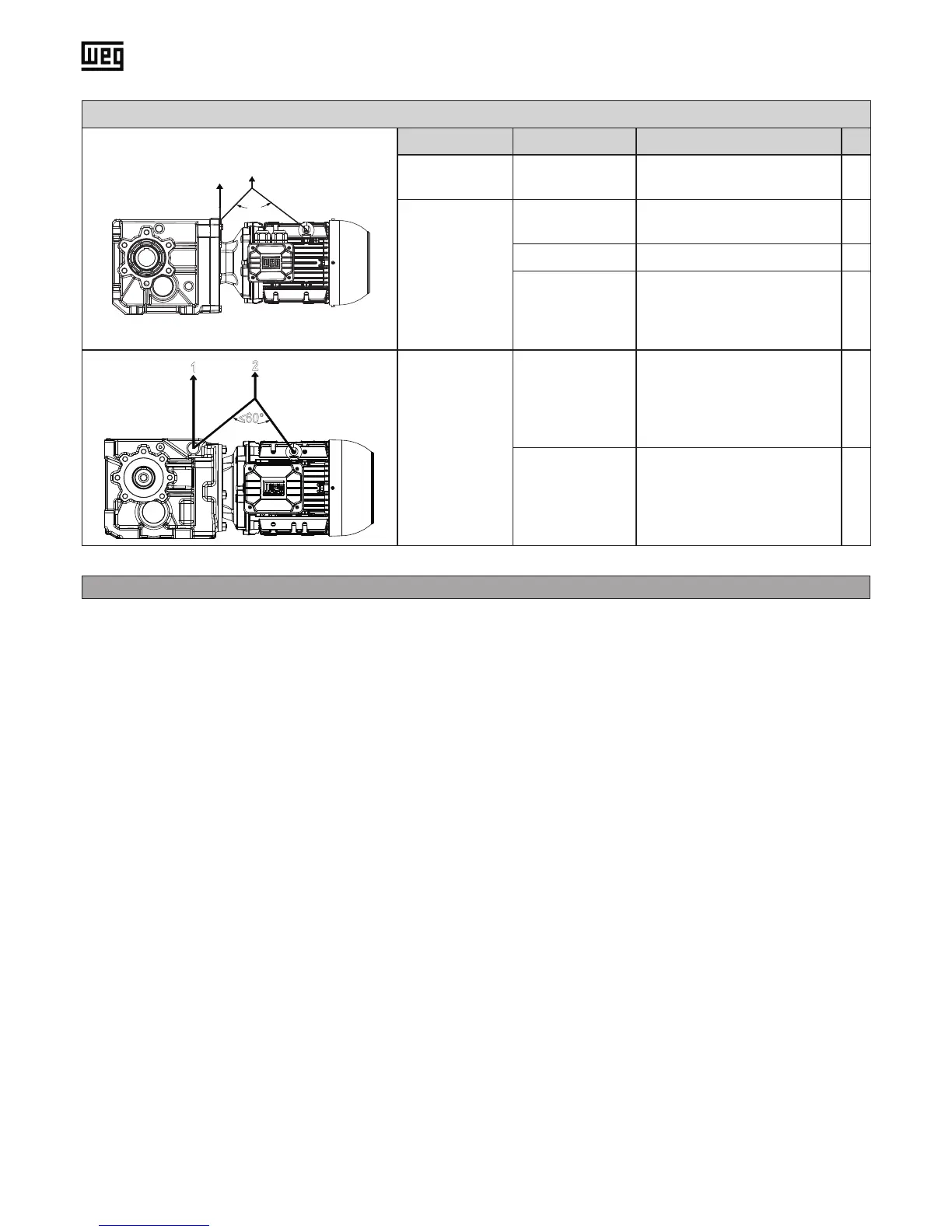

<

60°

1

2

K06

K07

63 - 90 Lifting eye on the gearbox 1

100 - 160

Lifting eye on the gearbox

+ eye bolt on motor

(max. angle of 60° between

the ropes)

2

Loading...

Loading...