E-28 | WG20 Geared Motors

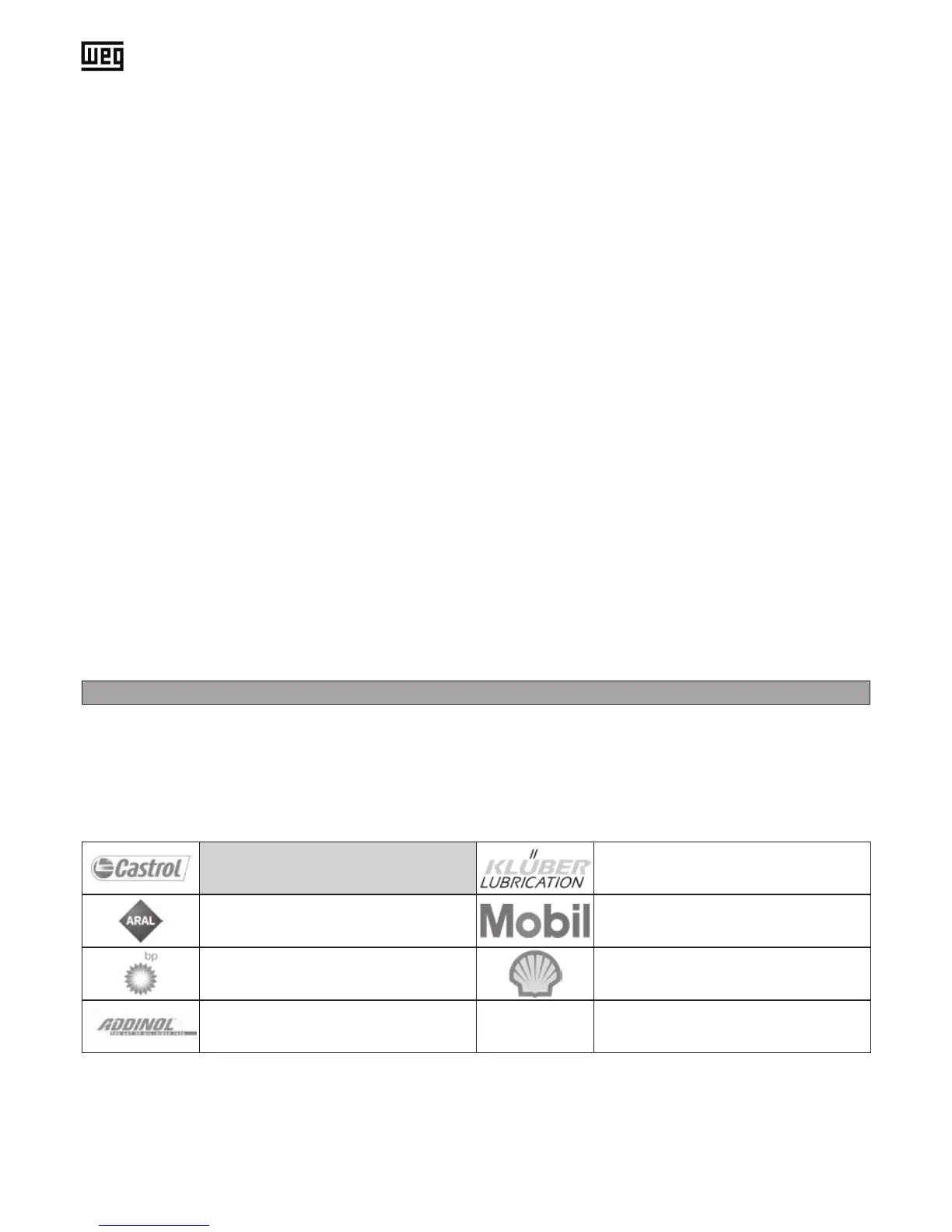

14. Lubricants

If a special agreement regarding the lubricant is not reached, the gear units shall be delivered factory-lled (see table

below marked grey). The specied gear ll amount and type is stated on the gear unit nameplate. The ll amount and oil

type can be different at special applications.

The following lubricant table shows the lubricants that are approved for WG20 gear units.

For helical, parallel shaft and helical bevel gear units at ambient temperatures -10 °C to +60 °C (14 °F to 140 °F)

Do not mix different types of lubricant!

Lubricants for other ambient conditions on request. Food proofed and biodegradable lubricants on request.

ALPHA SP 220 Klüberoil GEM 1-220 N

DEGOL BG 220 Mobilgear 600 XP 220

Energol GR-XP 220 Omala S2 GX220

Gear Oil 220 F

Remove dust deposits:

Remove any layers of dust that have accumulated on the gear unit. If the gear unit design included a protection cap, remo-

ve it and clean it too. Then reinstall the protection cap (see page E-22).

Change the shaft seals:

When changing the shaft seal, make certain that, depending on the design, a sufcient deposit of grease is present be-

tween the dust lip and the sealing lip.

When using double seals, ll one-third of the space between them with grease.

Oil change:

Let the gear cool down before beginning with the work! The oil has to be warm to make a complete emptying easier (poor

ow characteristics).

1. Put an appropriate container under the air vent and oil drain plug.

2. Remove the air vent and oil drain plug.

3. Let the oil drain completely.

4. Turn the plug in again completely.

5. Fill in the prescribed amount of oil over the vent plug (oil ll capacity see gear nameplate, permitted lubricants see page

E-28).

6. Tighten the vent plug completely again.

7. Dispose the used oil according to applicable regulations.

General overhaul:

The general overhaul is to be performed by the producer or by an authorised service partner.

Adjustment of air gap: see page E-35.

Nachträgliche Lackierung: Wird das Getriebe nachträglich neu lackiert, müssen Wellen, Wellendichtringe, Montage-

ächen, Gummibauteile, Entlüftungsventile, Ölschaugläser, Typenschilder und Aufkleber frei von Farben, Lacken und

Lösungsmitteln bleiben, um Beschädigungen und Unlesbarkeit zu vermeiden.

Loading...

Loading...