Lit. No. 27366, Rev. 01 February 15, 2008

17

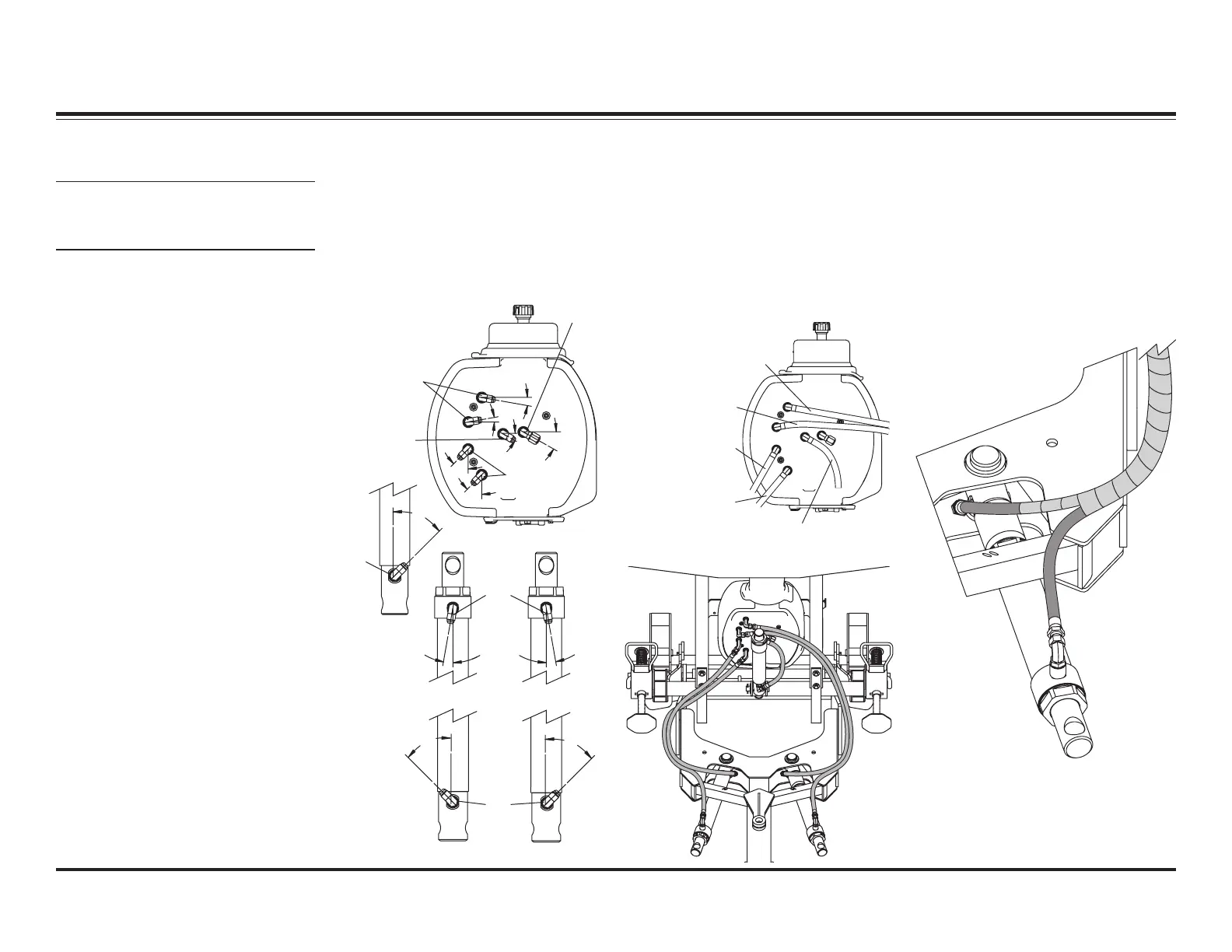

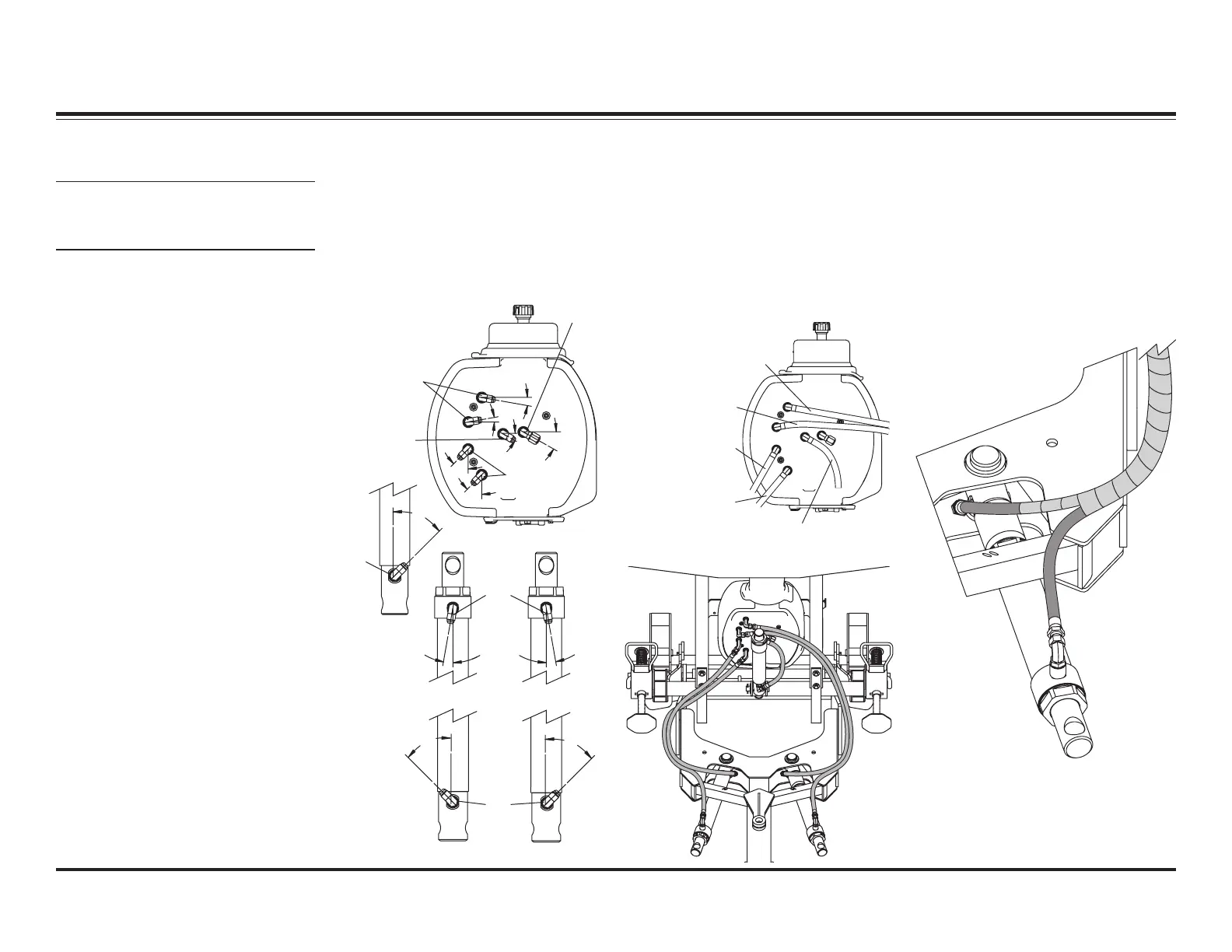

SYSTEM OVERVIEW – HYDRAULIC

NOTE: Overtightening JIC hose

fitting ends will result in a

fractured fitting.

Do not use thread sealant or tape on

hoses and fittings. This could

damage product.

Use the following procedure and

fitting orientation illustrations to

install SAE O-ring fittings in valve

block and rams.

1. Remove plug from ram or

manifold port. Use a rag to catch

residual fluid when removing

manifold plugs.

2. Turn jam nut on fitting as far back

as possible.

3. Lubricate O-ring with clean

hydraulic fluid.

4. Screw fitting into port by hand as

far as it will go. The washer

should contact port face and

shoulder of jam nut threads.

5. Unscrew fitting to proper position,

no more than one full turn.

6. Use one wrench to hold fitting

body in position and tighten the

jam nut with another wrench until

the washer again contacts port

face. Tighten 1/8–1/4 turn to lock

fitting in place.

HYDRAULIC FITTING AND HOSE INSTALLATION

PS Rod End

PS Base End

DS Rod End

Lift Ram

45°

90°

Elbow

10°10°

90°

Elbow

45°

DS Base End

45°

90°

Elbow

Angle Rams

Hydraulic Unit

Long 90°

Elbows

90° Elbow

and Cap

Long 90°

Elbows

90°

Elbow

10°

45°

45°

30°

30°

10°

Use the following procedure and

illustrations to install hydraulic

hoses.

1. Attach all hoses to fittings,

routing hoses as shown. Leave

hoses finger tight at this time.

1/4" x 36" Hose

To Passenger-

Side Rod (Front)

3/8" x 45" Hose

To Driver-Side

Base (Rear)

3/8" x 38" Hose

To Passenger-

Side Base (Rear)

1/4" x 12" Hose

To Lift Ram

1/4" x 42" Hose

To Driver-Side

Rod (Front)

2. Wrap angle ram hoses with

protective hose wrap as shown.

Start wrap on base end hose so

wrap covers diagonal brace.

Group hoses away from brace

and continue wrapping, forming a

smooth outward loop to the

hydraulic unit.

3. Using a wrench to hold the hose

end in position, tighten all hose

fittings 1/8–1/4 turn past finger

tight.

Excerpts taken from MVP PLUS™ Snowplow Installation Instructions (Lit. No. 44229, Rev. 05).

Loading...

Loading...