Lit. No. 27366, Rev. 01 February 15, 2008

79

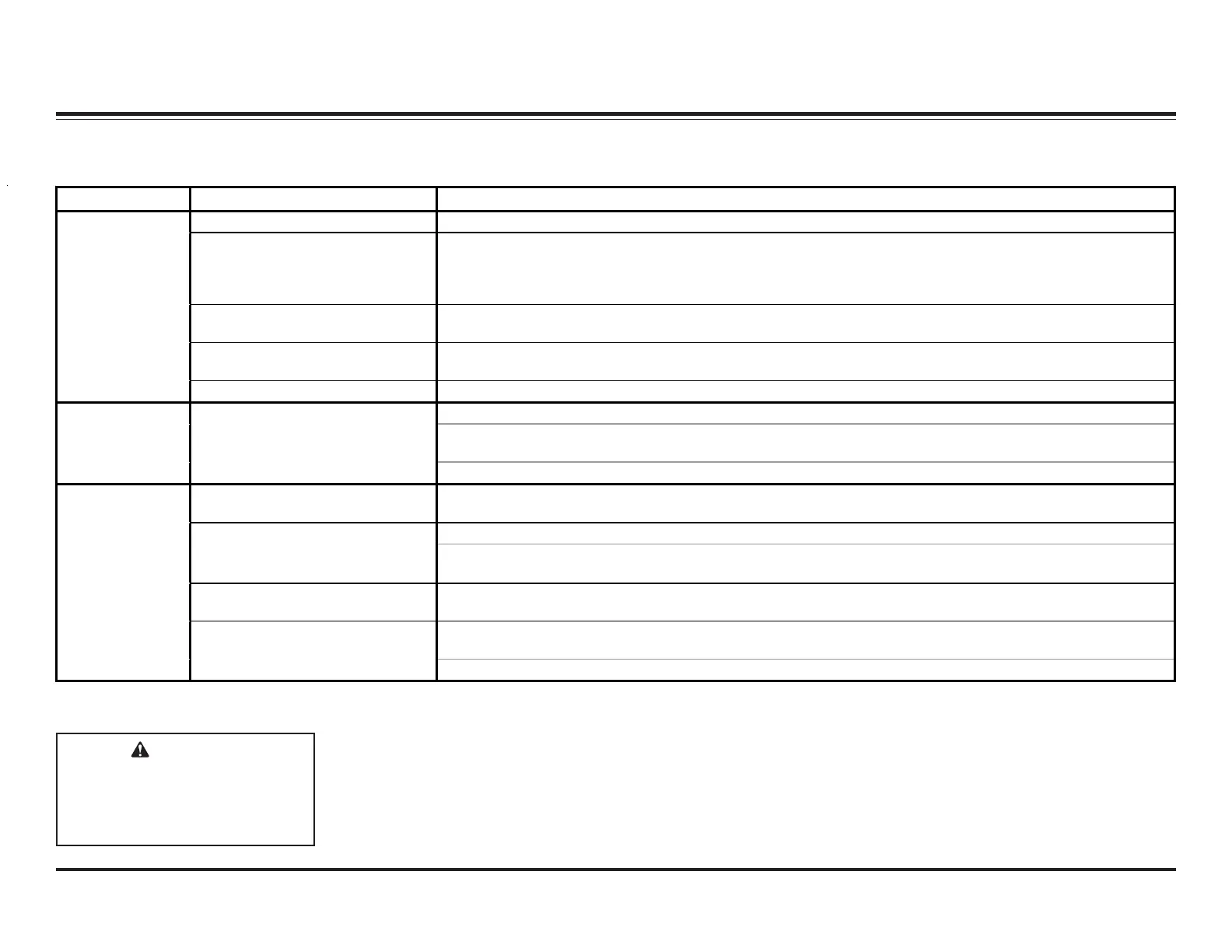

TROUBLESHOOTING GUIDE

CAUTION

Circuit board may be damaged

by static electricity. Always

touch ground before handling

PC board.

To Safely Handle PC Board:

Before disassembling control and

touching the PC board, be sure to

remove any static charge from

yourself. Static charge can build up

as a technician works on the control.

Best practice is to work at a properly

grounded work station with a

grounded wrist strap attached to the

technician. In place of proper work

station, the technician should work in

an oil and solvent free area and

touch a good ground each time

before touching the PC board while

servicing the unit.

Handle the PC board by the edges

only.

Do not touch the carbon (black)

areas of the keypad. Your skin oils

will deteriorate the contact area.

CONTROL/CABLE/PLOW MODULE TEST

CONDITION POSSIBLE CAUSE CORRECTIVE ACTION

Snowplow is not connected • Make sure grille plugs between snowplow and truck are properly connected.

Incomplete harness connection(s) or

damaged harness(es)

• With the vehicle switched accessory ON, test the 4-pin connector inside the cab. If pin 1 does not have 12V

and/or if pin 4 does not have ground, use the electrical schematic in this guide to trace the wires from the

connector back to their source. Look for incomplete connections or damaged wires. Complete connections or

repair/replace damaged wires and harnesses as needed.

Single-pin connector on vehicle

lighting harness is not connected.

• Make sure single-pin connector on vehicle lighting harness is properly connected.

Harnesses connected to Isolation

Module incorrectly.

• Using the electrical schematic in this guide, verify that Isolation Module and harnesses are properly

connected.

Control power

light is not ON.

Control fuse is blown. • Replace all blown fuses in under hood electrical harnesses.

• Make sure all plugs (control, between the snowplow and truck, on the snowplow, etc.) are properly connected.

• If all plugs are properly connected, install a properly working control. If problem is corrected, replace PC board

and/or coiled cord in damaged control.

Control power

light is blinking.

Poor connection, Damaged control

or Damaged Plow Module

• If problem is not corrected with properly working control, replace Plow Module.

Harnesses connected to Isolation

Module incorrectly.

• Using the electrical schematic in this guide, verify that Isolation Module and harnesses are properly

connected.

• Replace all blown fuses on truck and snowplow.

Blown fuse or Damaged Plow

Module

• If fuses are all okay, check for 12V at all coils and primary terminal of motor relay. If 12V is missing from any

coil or relay, replace Plow Module. If 12V is present, go to next Possible Cause.

Damaged harness(es) or cable(s)

• Perform a Solenoid Coil Activation Test (SCAT) according to the instructions in this guide. Replace/repair any

damaged harnesses and cables.

• Install a properly working control. If problem is corrected, replace PC board and/or coiled cord in damaged

control.

Control power

light is ON, but

snowplow does

not respond.

Damaged control or Plow Module

• If problem is not corrected with properly working control, replace Plow Module.

Loading...

Loading...