Lit. No. 27366, Rev. 01 February 15, 2008

82

TROUBLESHOOTING GUIDE

Inspection

1. Remove the valve stem, ball,

spacer and spring.

2. Look for broken or damaged

parts, contamination or missing

or damaged O-rings.

3. If parts are OK, place ball on

hard wood block, hold stem seat

on ball and lightly strike top of

stem with a hammer. This will

seat the ball and valve stem.

4. Apply a light coat of anti-seize or

grease to stem threads.

Lubricate O-rings with hydraulic

fluid. Reassemble components

into valve block.

CAUTION

Be careful to strike stem

squarely. You can bend stem if

you do not strike it squarely.

CAUTION

Never operate the unit while

adjusting the relief valve.

Doing so will damage the relief

valve O-rings.

Adjustment

1. Screw stem in until spring is fully

compressed.

2. Back out (counterclockwise) the

number of turns in the following

chart.

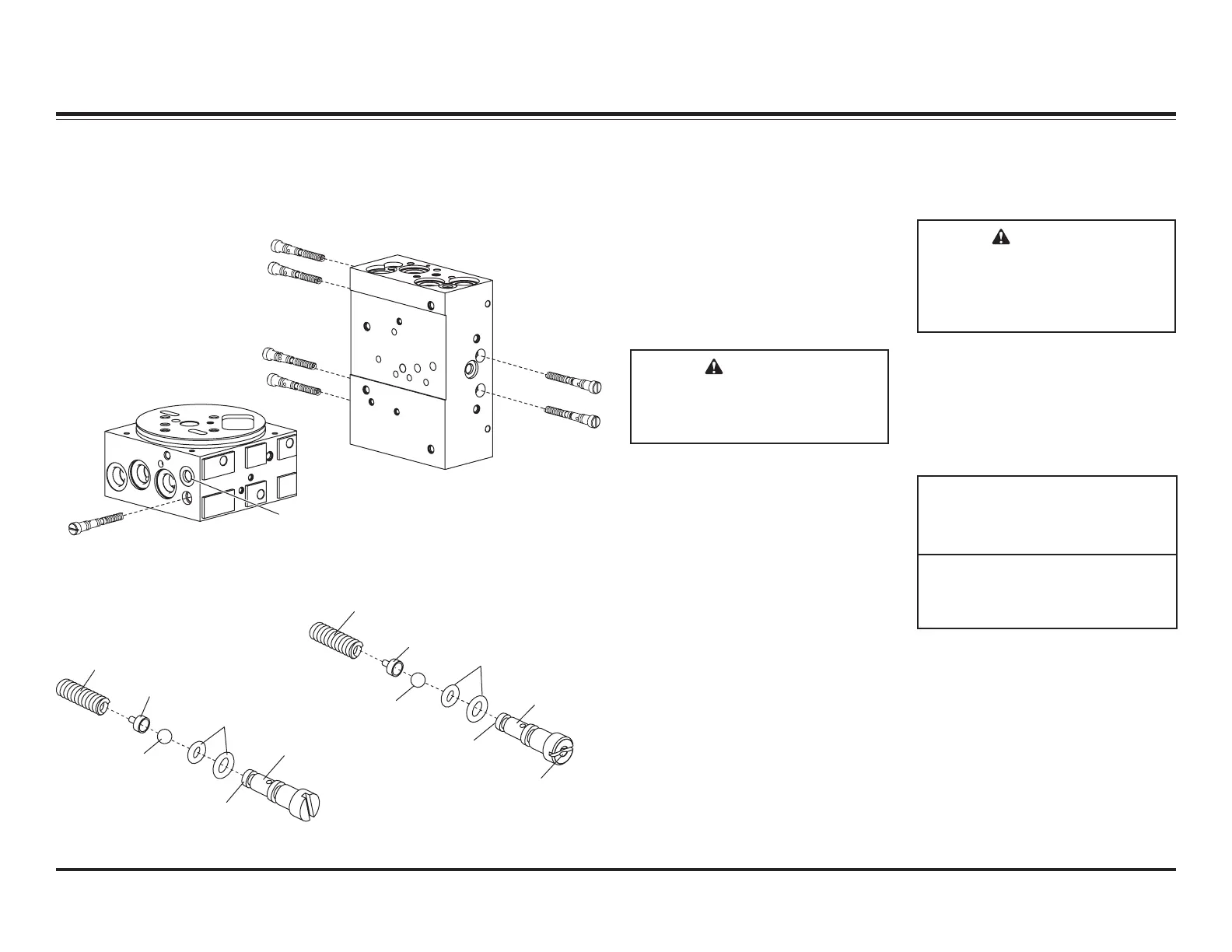

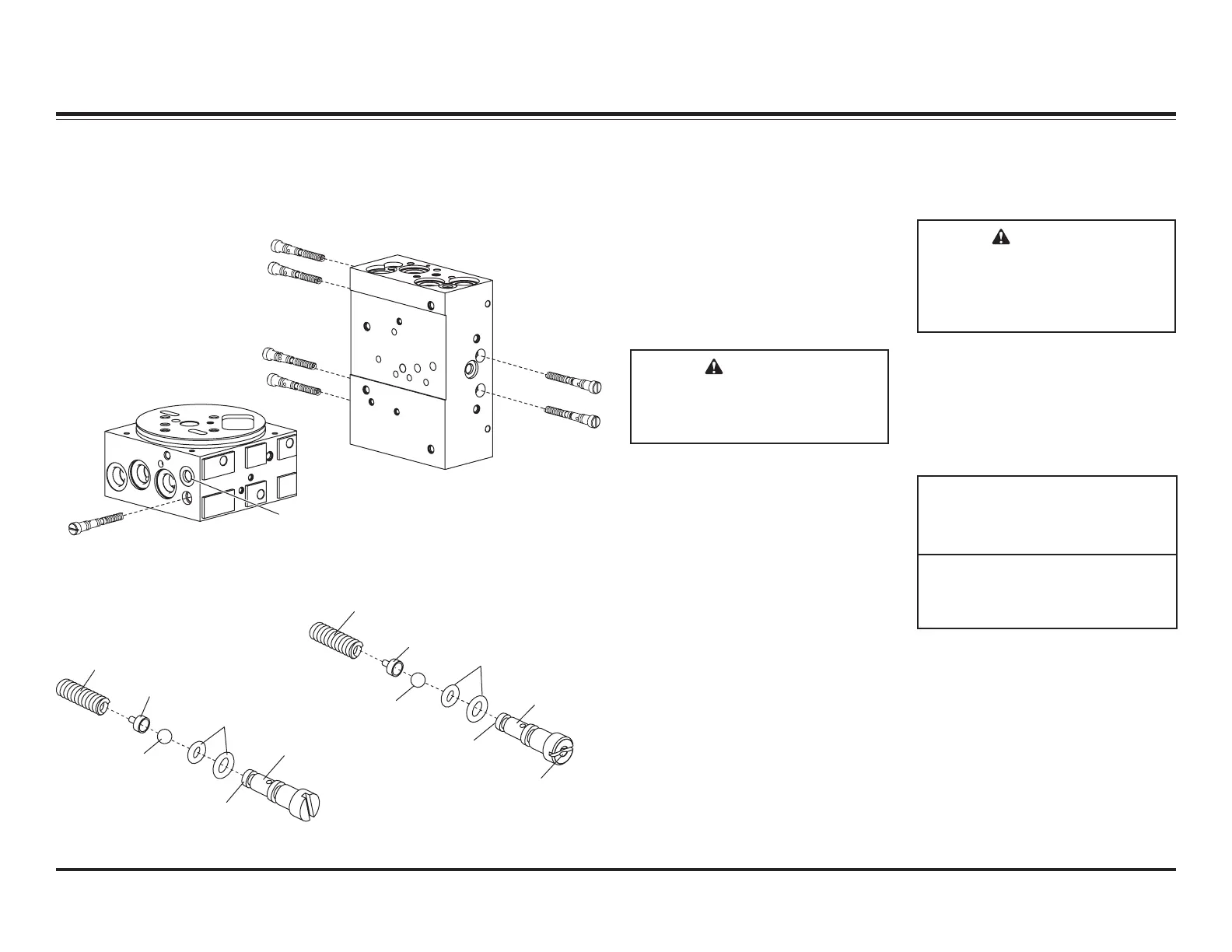

RELIEF VALVE INSPECTION AND ADJUSTMENT

Relief valves B and components are not interchangeable with A and C. The

stem is marked with a drill point in the screwdriver slot for identification.

Assembly A & C

1/4" Ball

.125 Ø Hole

Valve Stem

Seat

O-Rings

Spring

Spacer

Valve Stem

Assembly B

Drill Point

Identification

Mark

7/32" Ball

.115 Ø Hole

Valve Stem

Seat

O-Rings

Spring

Spacer

Valve Stem

PS

B

Base-End

Relief Valves

C

Pump Relief Valve

Pressure

Test Port

DS

A

Rod-End

Relief Valves

PS

DS

A (Qty 2)

B (Qty 4)

C (Qty 1)

1-1/4

1-1/4

2-1/2

3700

4600

2250*

Relief

Valve

Approx.

Pressure

(psi)

# of Turns

Out (ccw)

from

Fully Seated

* See the Pump Pressure Test

Section for details.

Loading...

Loading...