20

WILDEN PUMP & ENGINEERING, LLC WIL-10230-E-02

SECTION 8C

REASSEMBLY HINTS & TIPS

ASSEMBLY:

Upon performing applicable maintenance to the air distribu-

tion system, the pump can now be reassembled. Please

refer to the disassembly instructions for photos and parts

placement. To reassemble the pump, follow the disassem-

bly instructions in reverse order. The air distribution system

needs to be assembled first, then the diaphragms and finally

the wetted path. Please find the applicable torque speci-

fications on this page. The following tips will assist in the

assembly process.

• Clean the inside of the center section shaft bushing to

ensure no damage is done to new seals.

• Stainless bolts should be lubed to reduce the possibility

of seizing during tightening.

• Ensure proper alignment on the sealing surfaces of intake

and discharge manifolds.

• Liquid chambers are easier to attach when the diaphragm

is inverted. Prior to attaching the second water chamber,

push diaphragm assembly so that it is as close as possi-

ble to the center section.

• PVDF and PFA pumps require PTFE gasket kits for

improved sealing. Gasket kits may be installed on other

pumps where sealing is an issue.

• When assembling PTFE-coated hardware, care should

be taken to keep the coating intact.

• When installing Glyd™ rings, the use of the Wilden Ringer

tool simplifies seal installation.

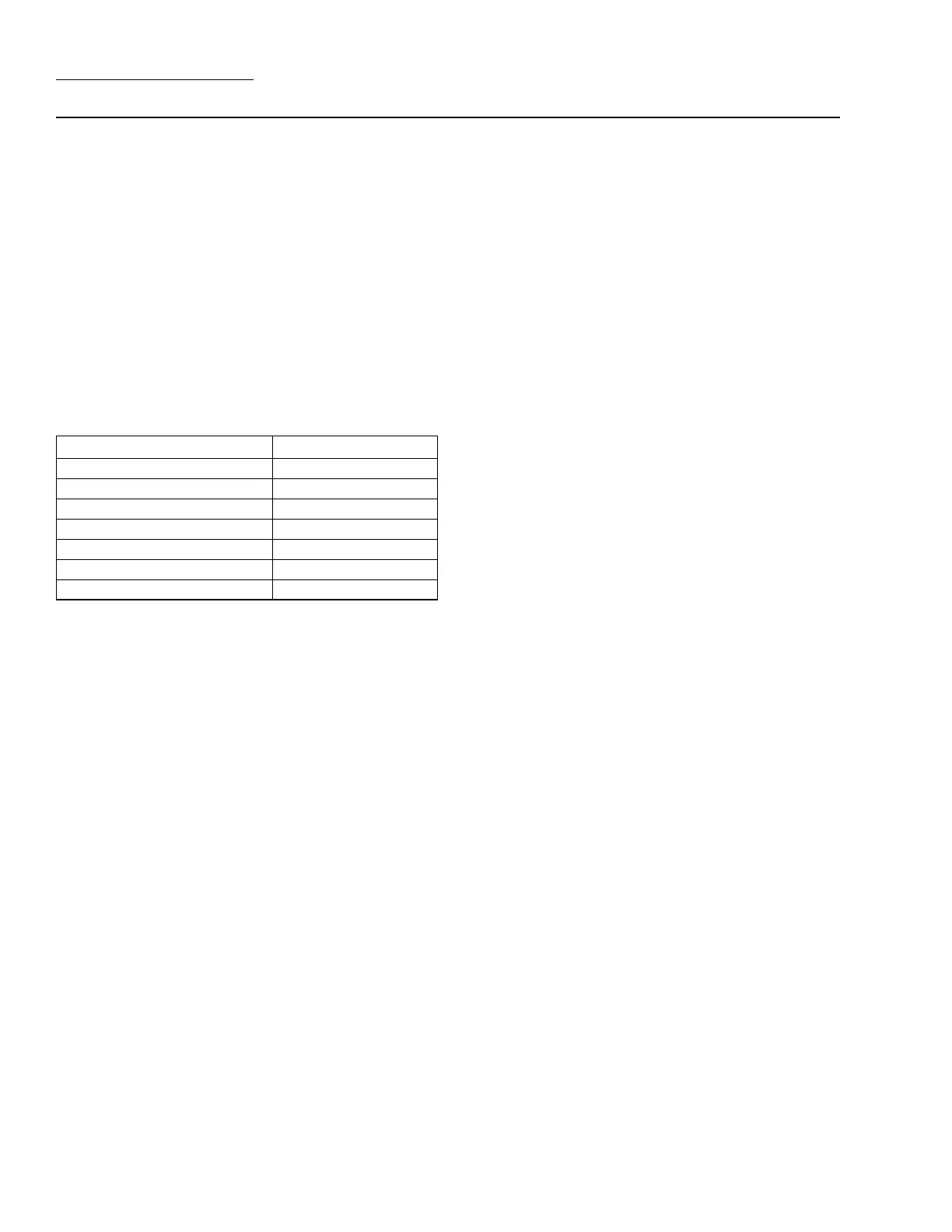

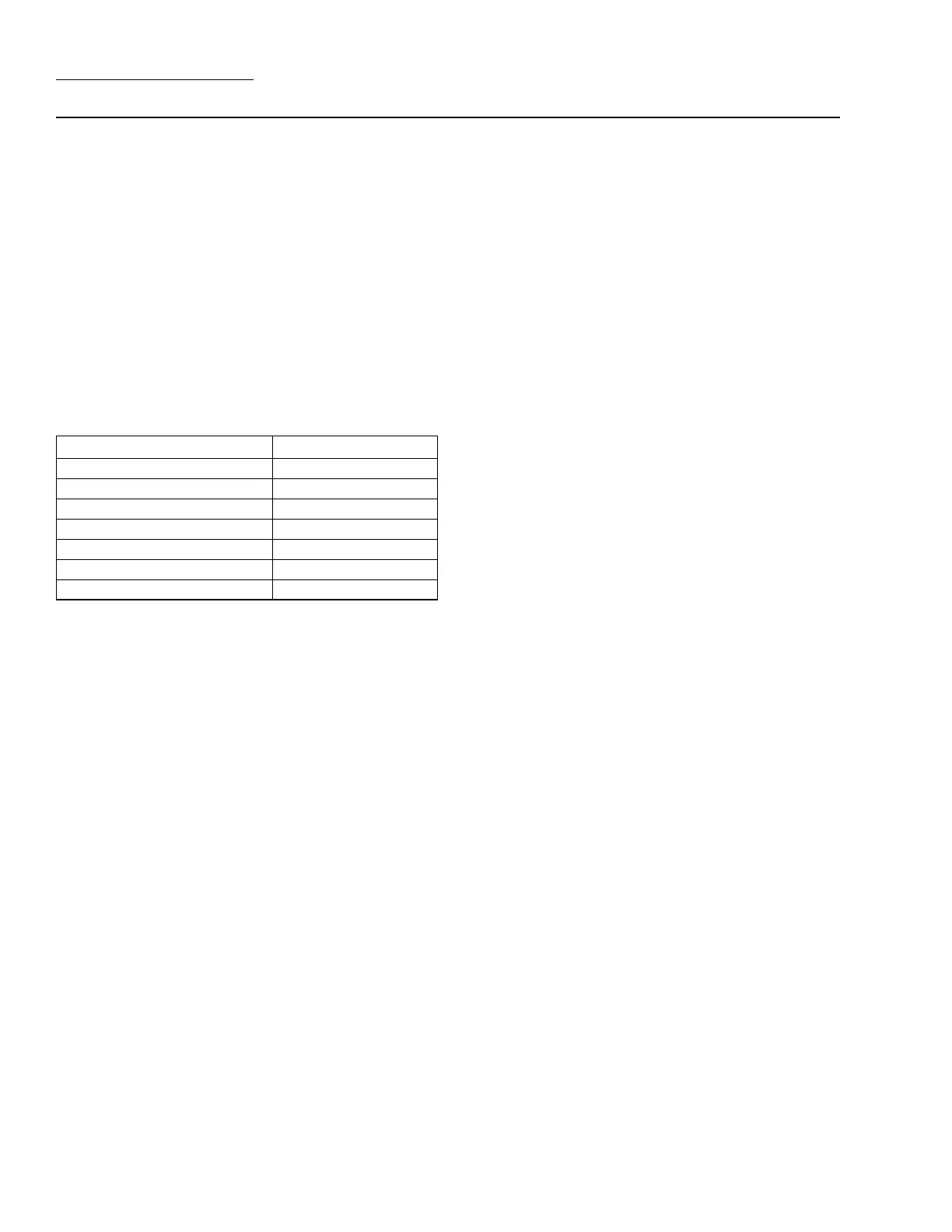

MAXIMUM TORQUE SPECIFICATIONS

Description of Part Plastic Pumps

Air Valve 6.8 N•m (60 in-lbs)

Outer Piston (PTFE-fi tted) 81.3 N•m (58 ft-lbs)

Outer Piston (Rubber-fi tted) 81.3 N•m (58 ft-lbs)

Small Clamp Band (All) 6.2 N•m (55 in-lbs)

Medium Clamp Band 10.2 N•m (90 in-lbs)

Large Clamp Band (All) 40.0 N•m (28 ft-lbs)

Center Block Assembly 47.5 N•m (35 ft-lbs)

Loading...

Loading...