21

WILDEN PUMP & ENGINEERING, LLCWIL-10230-E-02

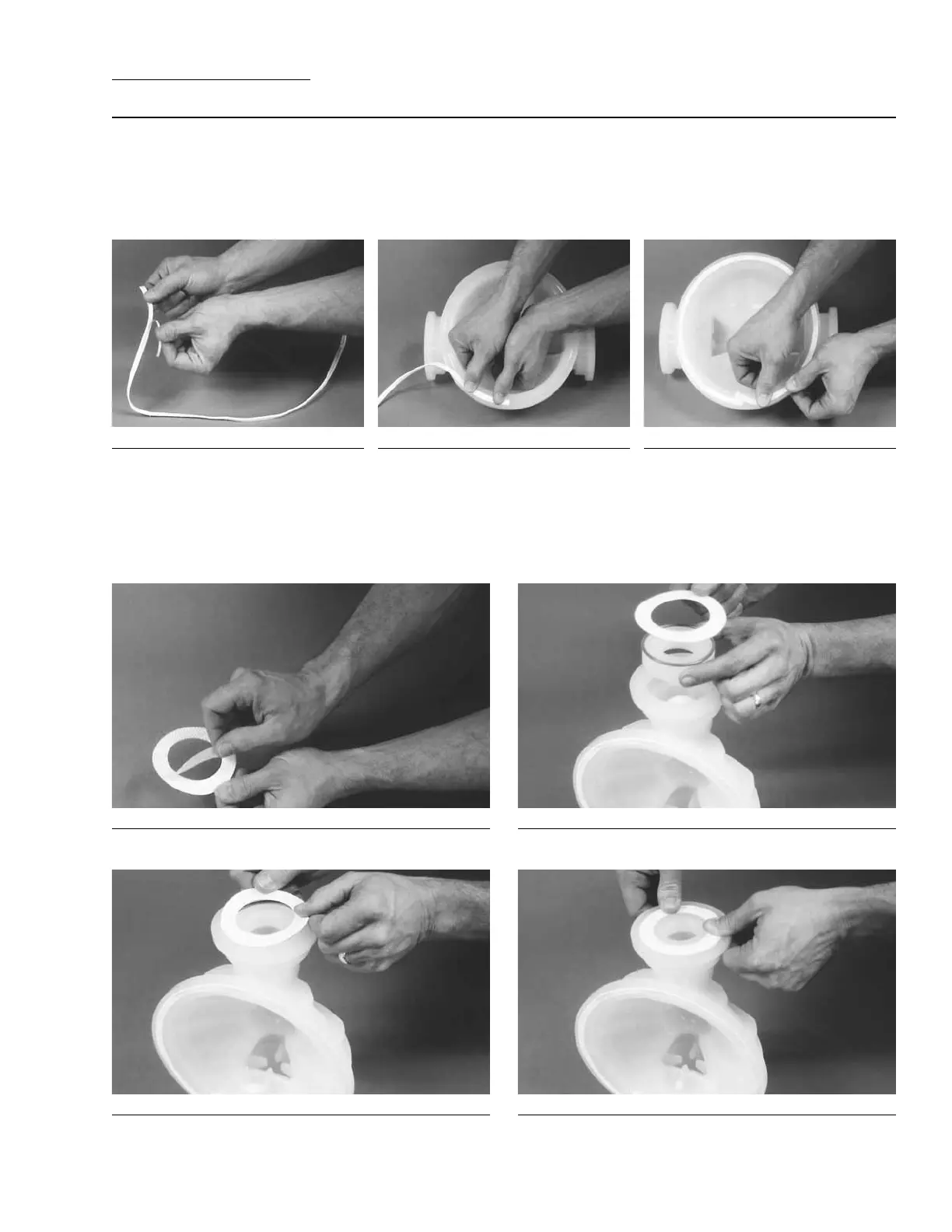

Step 1. Figure 1

Gently remove the adhesive covering

from the back of the PTFE tape. Ensure

that the adhesive strip remains attached

to the PTFE tape.

Step 2. Figure 2

Starting at any point, place the PTFE

tape in the center of the diaphragm

bead groove on the liquid chamber and

press lightly on the tape to ensure that

the adhesive holds it in place during

assembly. Do not stretch the tape during

placement in center of diaphragm bead

groove.

Step 3. Figure 3

The ends of the tape should overlap

approximately 13 mm (1/2”). Proceed to

install the PTFE tape on the remaining

liquid chamber.

Only PTFE-fitted T8 PVDF and polypropylene pumps come

standard with expanded PTFE Gasket Kits (P/N 08-9503-

99 for PVDF and 08-9502-99 for polypropylene). Carefully

prepare sealing surfaces by removing all debris and foreign

matter from diaphragm bead and all mating surfaces. If neces-

sary, smooth or deburr all sealing surfaces. Mating surfaces

must be properly aligned in order to ensure positive sealing

characteristics.

SECTION 8D

GASKET KIT INSTALLATION

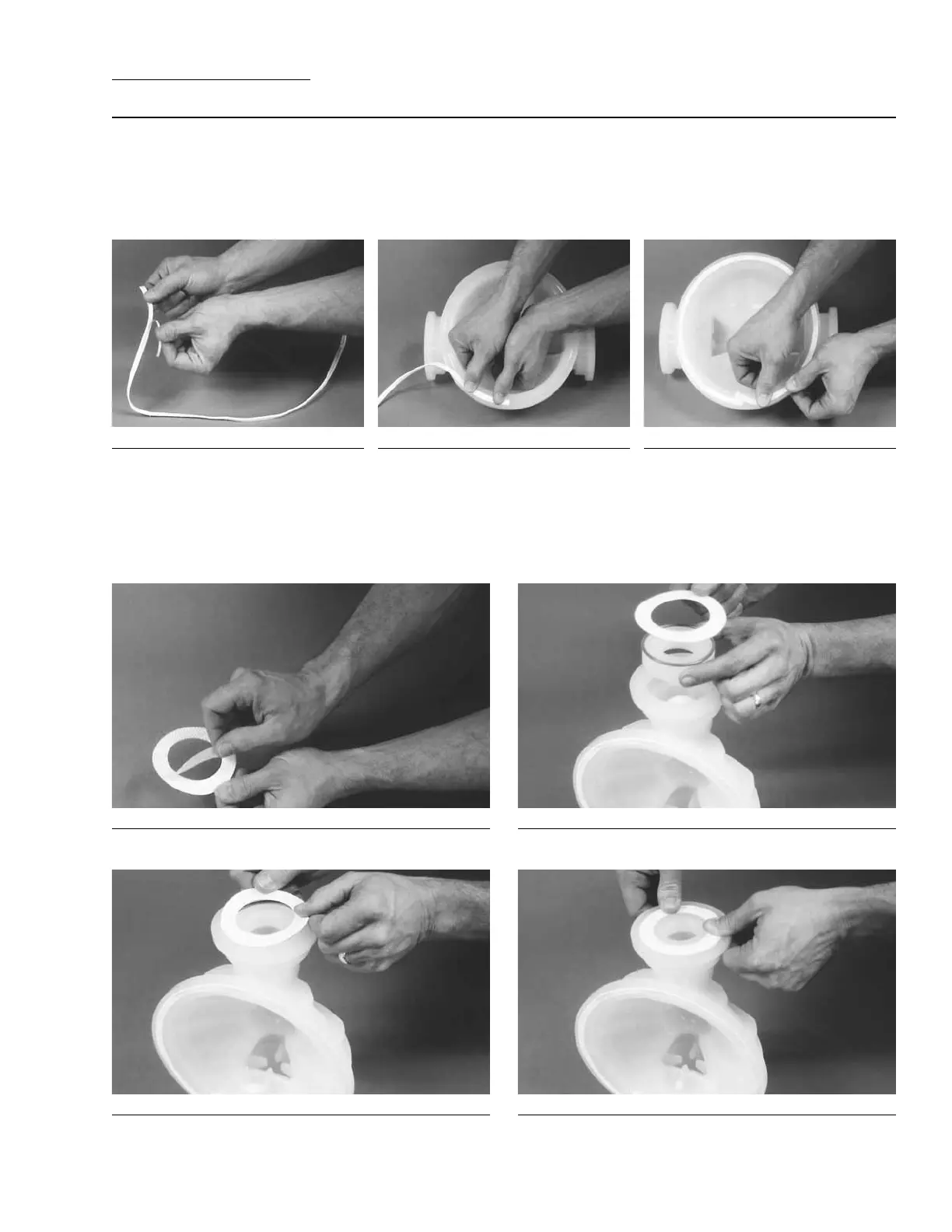

Step 4. Figure 4

Carefully remove the protective covering from the back of

the PTFE gasket attached to tape.

Step 5. Figure 5

Install the valve ball, valve seat and o-ring.

Step 6. Figure 6

Center the gasket so that it evenly covers the o-ring and

seat areas.

Step 7. Figure 7

Gently apply pressure to gasket to ensure the adhesive main-

tains a positive seal to stay in place during pump assembly.

PVDF

PVDF AND POLYPROPYLENE

Loading...

Loading...