6

WILDEN PUMP & ENGINEERING, LLC WIL-10230-E-02

SECTION 5C

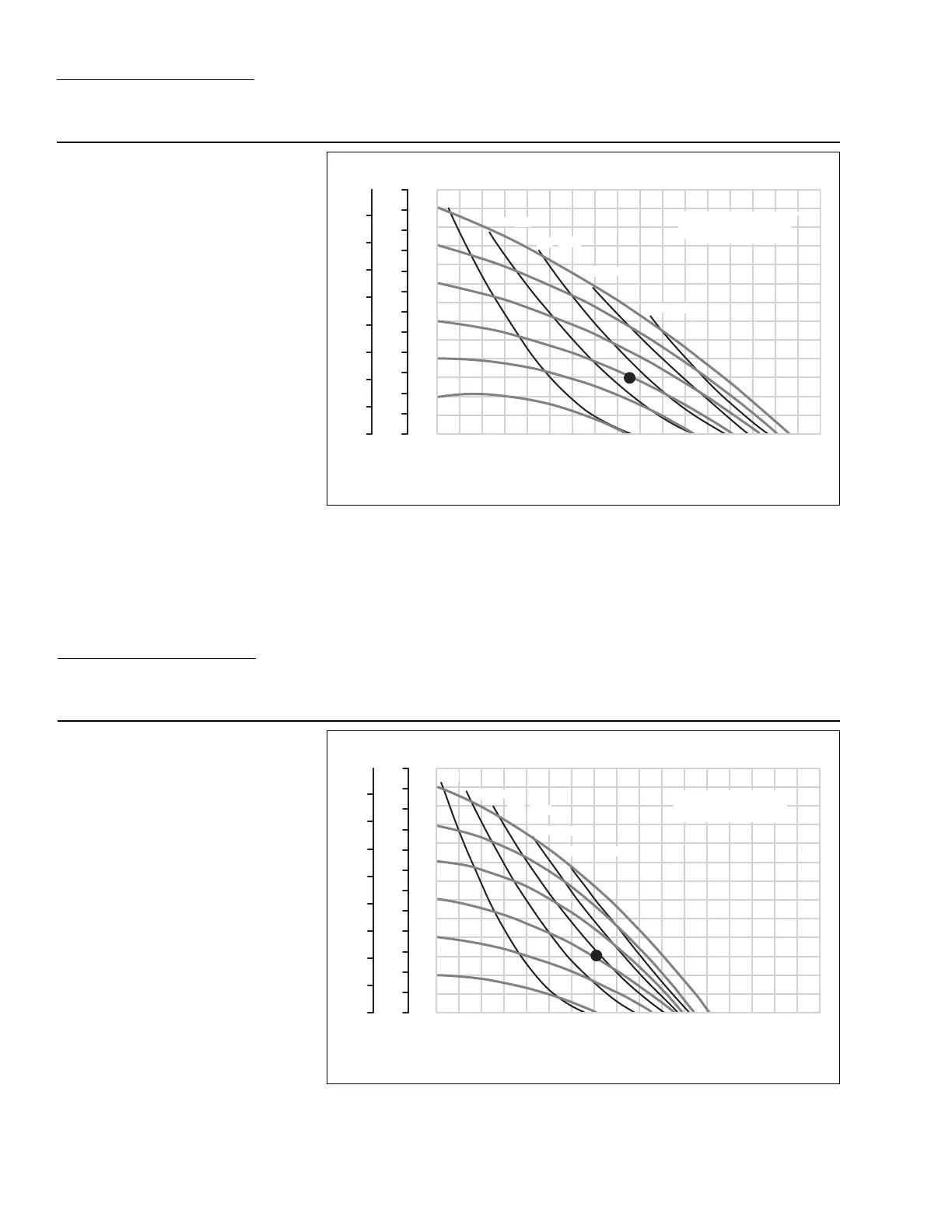

PERFORMANCE CURVES

T8 PLASTIC TPE-FITTED

Height ..................................770 mm (30.3”)

Width ...................................490 mm (19.3”)

Depth ..................................333 mm (13.1”)

Est. Ship Weight ........Polypropylene 35 kg (77 lbs)

Air Inlet ....................................19 mm (3/4”)

Inlet ............................................51 mm (2”)

Outlet .........................................51 mm (2”)

Suction Lift ...........................4.6 m Dry (15’)

9.5 m Wet (31’)

Displacement / Stroke ..... 2.91 l (0.77 gal.)

1

Max. Flow Rate ...............591 lpm (156 gpm)

Max. Size Solids .....................6.4 mm (1/4”)

1

Displacement per stroke was calculated at 4.8 bar

(70 psig) air inlet pressure against a 2 bar (30 psig)

head pressure.

Example: To pump 322 lpm (85 gpm) against

a discharge pressure head of 2 bar (30 psig)

requires 4.1 bar (60 psig) and 85 Nm

3

/h (50

scfm) air consumption. (See dot on chart.)

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

(20) [34]

(40) [68]

(60) [102]

(80) [136]

(100) [170]

AIR CONSUMPTION

(SCFM) [Nm

3

/h]

20 40 60 80 100 120 140 160

PSIG

20

40

60

80

100

120

FEET

0

25

50

75

100

125

150

175

200

225

250

275

300

BAR

0

1

2

3

4

5

6

7

8

GPM

[LPM]

[76] [151] [227] [303] [378] [454] [530]

Discharge Pressure

[606]

Water Discharge Flow Rates

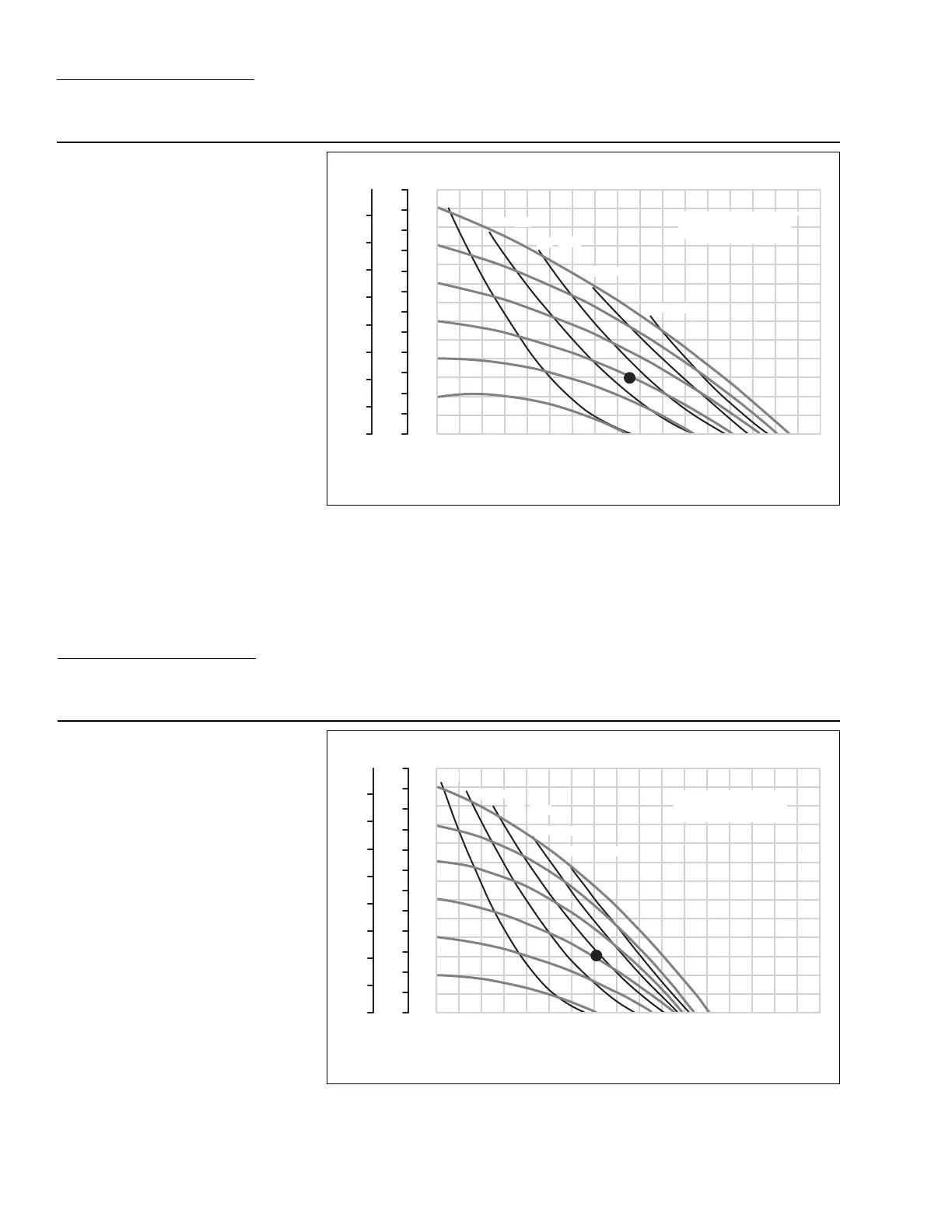

SECTION 5D

PERFORMANCE CURVES

T8 PLASTIC PTFE-FITTED

Height ..................................770 mm (30.3”)

Width ...................................490 mm (19.3”)

Depth ..................................333 mm (13.1”)

Est. Ship Weight ........Polypropylene 35 kg (77 lbs)

Air Inlet ....................................19 mm (3/4”)

Inlet ............................................51 mm (2”)

Outlet .........................................51 mm (2”)

Suction Lift ...........................3.1 m Dry (10’)

9.5 m Wet (31’)

Displacement / Stroke ...... 1.51 l (0.40 gal)

1

Max. Flow Rate ...............458 lpm (121 gpm)

Max. Size Solids .....................6.4 mm (1/4”)

1

Displacement per stroke was calculated at 4.8 bar

(70 psig) air inlet pressure against a 2 bar (30 psig)

head pressure.

Example: To pump 265 lpm (70 gpm) against

a discharge pressure head of 2 bar (30 psig)

requires 4.1 bar (60 psig) and 93.5 Nm

3

/

h (55 scfm) air consumption. (See dot on

chart.)

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

AIR CONSUMPTION

(SCFM) [Nm

3

/h]

20 40 60 80 100 120 140 160

PSIG

20

40

60

80

100

120

FEET

0

25

50

75

100

125

150

175

200

225

250

275

300

BAR

0

1

2

3

4

5

6

7

8

(20) [34]

(40) [68]

(60)

[102]

(80) [136]

(100) [170]

GPM

[LPM]

[76] [151] [227] [303] [378] [454] [530]

Discharge Pressur

e

[606]

Water Discharge Flow Rates

Loading...

Loading...