50 3062555_201804

Fluegastemperaturelimiter

The electronic ue gas temperature limiter switches the oil

condensingboileroffwhentheuegastemperatureexceeds

110 °C.

Theappliancewillrestartoperationwhenthe

restbuttonispressed.Itisimportanttondout

whytheappliancedeactivatedbeforeresetting

the boiler. Resetting the boiler when the ue

gas temperature is too highcan destroy the

uegassystem.

Note

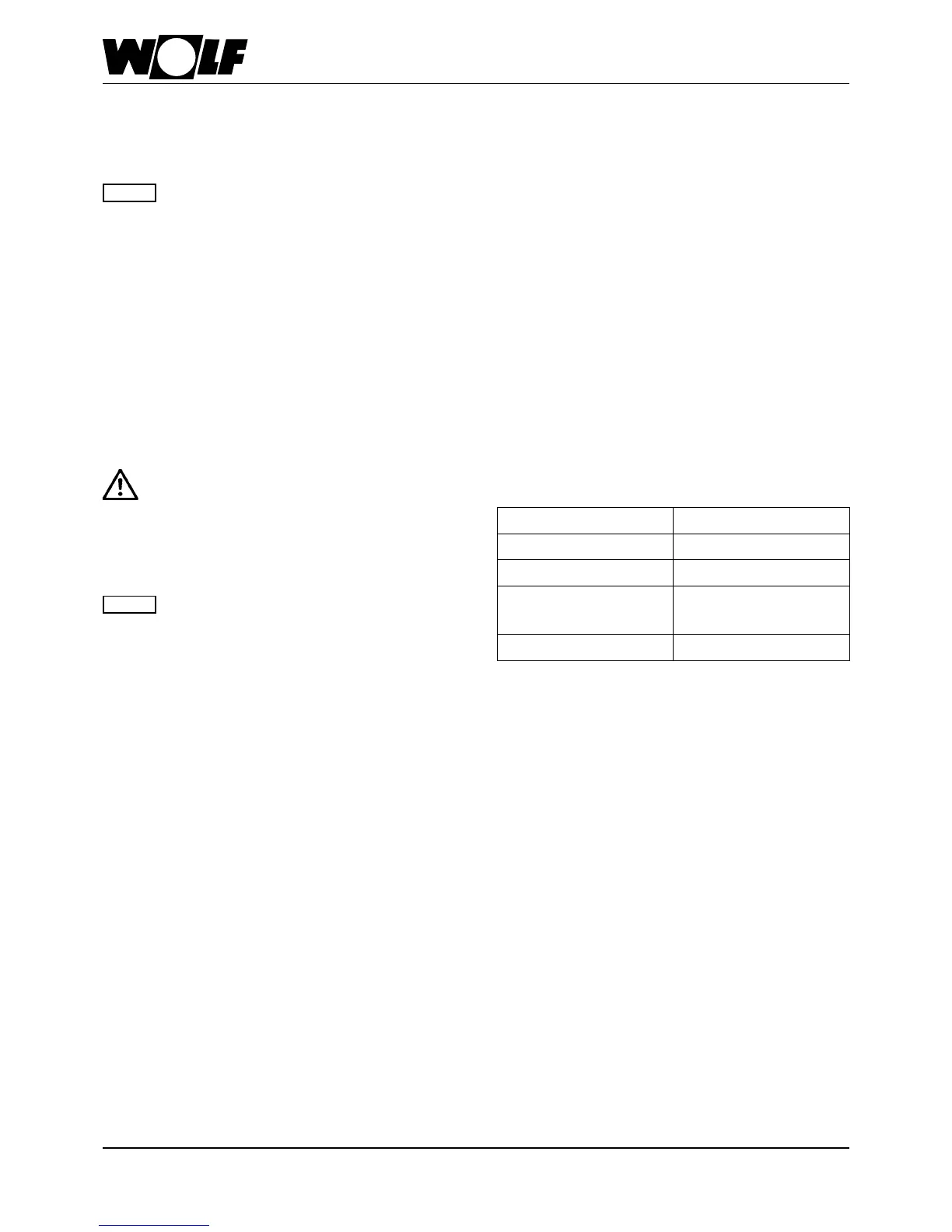

Calculatingthebalanceduelength

The calculated length of the air/ue gas routing system or

standard ue is derived from the straight pipe length and

the length of any pipe bends. In this calculation, a 87° bend

or a 87° tee is calculated as being 2 m and a 45° bend as

being 1 m.

For boilers with a rated heating output above 50 kW, a clear-

anceofat least1.0 mbetweenthe ueoutlet andthe roof

surface is required.

Example:

Lengthofstraightbalancedue1.5m

Inspectiontee87°=2m

2x45°bends=2x1m

L=1.5m+1x2m+2x1m

L=5.5m

Component Lengthtobeallowedfor

87° bend 2m

45° bend 1m

87° tee with

inspection port

2m

Straight pipe Corresponding to length

Table: Pipe length calculation

Connectiontotheair/uegasroutingsystem

It must be possible to inspect the entire cross-section of the

ues.Therefore,installanappropriatecleaningand/orinspec-

tion port inside the boiler room; agree suitable arrangements

withthelocaluegasinspector.

Flue connections are created using female connections and

gaskets. Always arrange female connections against the di-

rectionofthecondensateow.

Install the air/ue gas routing system with a

slopeofatleast3°(6cm/m)towardsthegas

condensingboiler.Installspacerclipstosecure

inplace(seeinstallationexamples).

Intheworstcasescenario,alesserslopeofthe

air/uegasroutingsystemmayleadtocorro-

sionoroperatingfaults.

Always bevel or deburr cut flues to ensure

gas-tight installation of pipe joints. En-

sure that gaskets are fitted correctly.Re-

move all contamination prior to installation.

–nevertdamagedparts.

Note

28.Technicalinformation

Loading...

Loading...