Do you have a question about the Wood-mizer LX250 and is the answer not in the manual?

Overview of the manual's purpose and scope.

Information on obtaining service, sales, and parts.

Details equipment specifications and references online manuals.

Explains how to identify the sawmill model, revision, and serial number.

Explains safety symbols and signal words used in the manual.

Covers owner/operator responsibilities and general safety rules.

Details the critical lockout/tagout procedures for electrical safety.

Lists necessary tools for sawmill assembly.

Step-by-step guide for safely removing the sawmill from its packaging.

Instructions for assembling the sawmill's bed sections and connecting them.

Procedures for mounting the end stops onto the sawmill frame.

Guidance on leveling the sawmill bed before installing the saw head.

Instructions for positioning and mounting the saw head onto the bed frame.

Steps for assembling and connecting the power feed drive system.

How to safely install a new bandsaw blade onto the sawmill.

Procedures for correctly tensioning the bandsaw blade using the tension gauge.

Steps to ensure the blade is tracking correctly on the blade wheels.

Covers sawblade specifics including guide alignment.

Instructions for safely starting the sawmill's engine.

Operation of the manual power feed system for mast movement.

How to manually raise or lower the cutting head.

Explanation of the Simple Set control for automated up/down adjustments.

Procedures for safely loading, turning, and clamping logs onto the sawmill bed.

Adjusting the blade guide arm for optimal cutting.

Detailed steps for cutting logs accurately and efficiently.

Process for edging flitches and boards to desired dimensions.

Using the blade height scale for accurate lumber thickness.

How to use the water lube system to keep the blade clean.

Guidelines for safely transporting the sawmill.

Estimated life expectancy for common replacement parts.

Maintenance procedures for the blade guide rollers.

Safe procedure for replacing the bandsaw blade.

Instructions for removing sawdust buildup from key areas.

Maintenance of the mast track, wipers, and scrapers for smooth operation.

Maintenance for the vertical mast rails.

General maintenance tasks including lubrication and decal checks.

How to adjust the drive belt tension for optimal performance.

Maintenance and adjustment procedures for the up/down system chain.

Steps for safely charging the sawmill's battery.

Identifies common sawing problems, their causes, and solutions.

Covers error messages, diagnostic lights, gear settings, and PID adjustments for the Simple Set system.

Covers error messages, diagnostic lights, gear settings, and PID adjustments for the Simple Set system.

Outlines the routine steps for aligning the sawmill to solve sawing issues.

Describes the comprehensive procedure for full sawmill alignment, performed periodically.

| Brand | Wood-mizer |

|---|---|

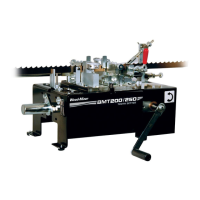

| Model | LX250 |

| Category | Industrial Equipment |

| Language | English |